Functional corneal contact lens and preparation method thereof

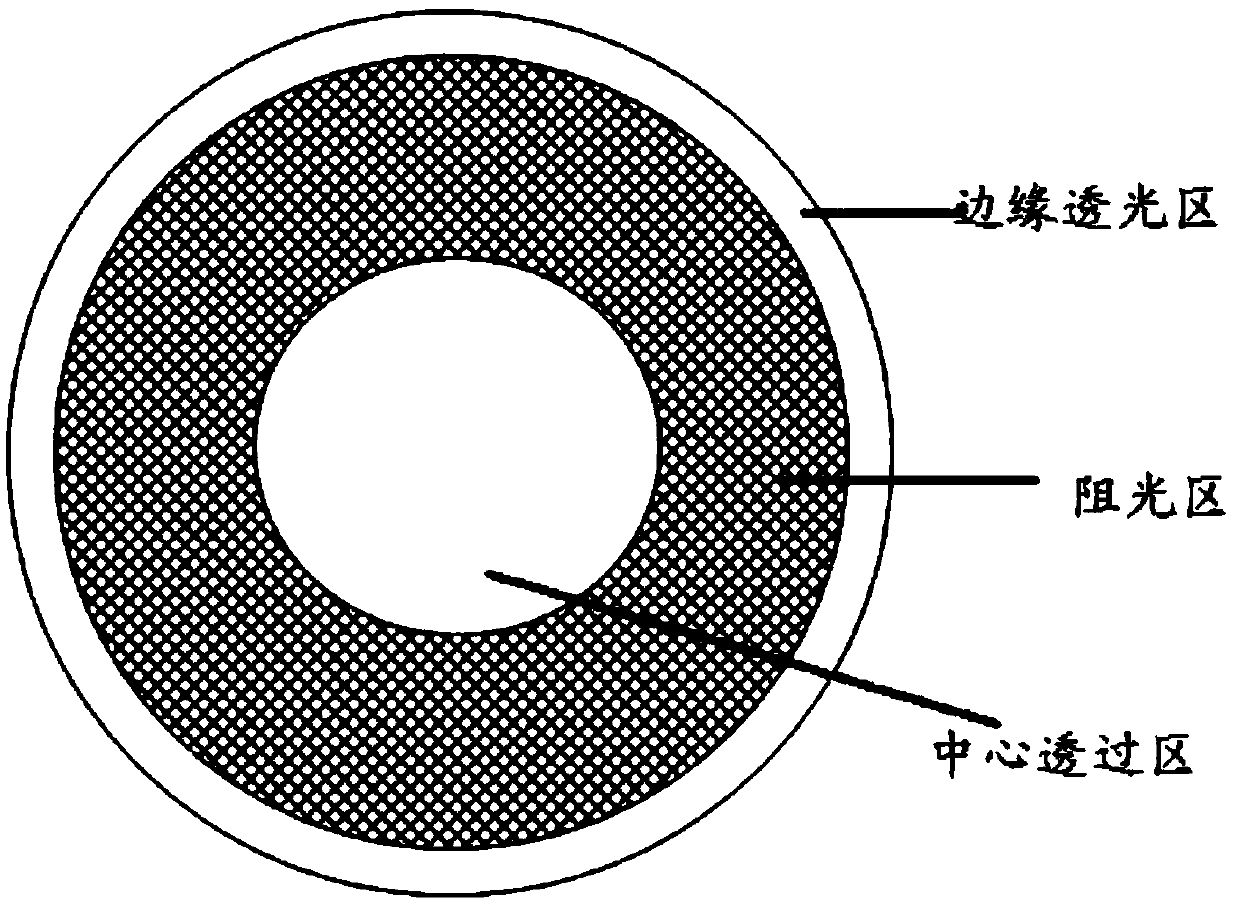

A corneal contact lens, functional technology, applied in glasses/goggles, coatings, instruments, etc., can solve the problems of photophobia, blurred vision, artificial iris and pupil size fixation of patients, and achieve correct iris defects, The effect of ensuring wearing comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

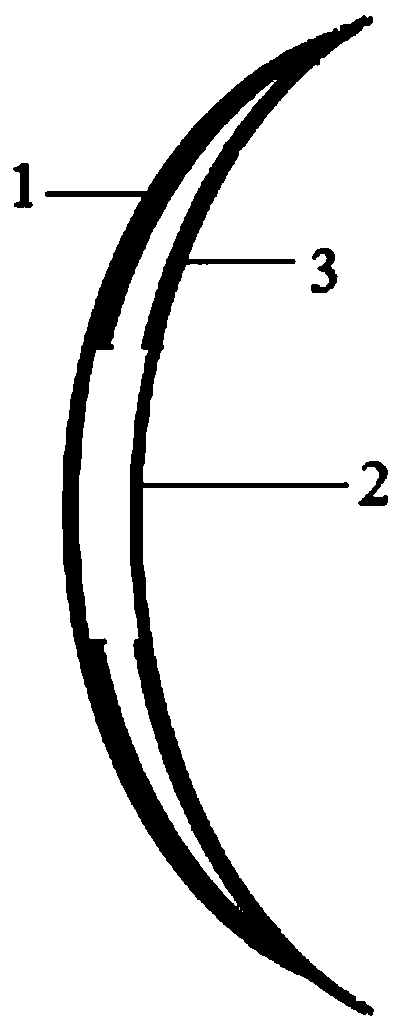

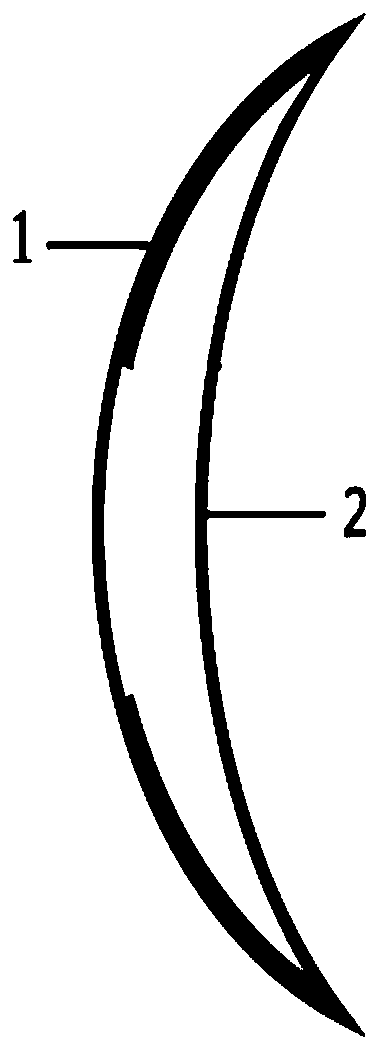

[0034] The present invention also provides a method for preparing a functional contact lens without a protective film described in the above technical solution, comprising the following steps:

[0035] The raw material mixture of the light-blocking layer is printed on the upper mold and / or the lower mold of the mold, and then the raw material mixture of the lens body is injected into the lower mold, and then the molds are closed and cured to obtain a functional contact lens.

[0036] The preparation method provided by the invention does not need to use a new mold, but can directly use the existing mold for preparing corneal contact lenses, and the preparation method is simple, easy to implement, and suitable for industrial production.

[0037] In the present invention, the raw material mixture of the light blocking layer preferably includes a pigment, a first main raw material, a first crosslinking agent, a first initiator, a binder and a solvent; the first main raw material is...

Embodiment 1

[0069] (1) Mix the following materials to obtain the raw material mixture of the light-blocking layer: iron oxide 3wt.%, phthalocyanine blue 3wt.%, hydroxyethyl methacrylate 32wt.%, ethylene glycol dimethacrylate 5wt.%, 32wt.% of 1-vinyl-2-pyrrolidone, 23.7wt.% of cyclopentanone, 1wt.% of n-dodecanethiol and 0.3wt.% of azobisisobutyronitrile; the viscosity of the raw material mixture of the light blocking layer 300000mPa;

[0070] (2) Print the raw material mixture of the light-blocking layer on the upper mold and the lower mold of the mould, the inner diameter of the printed light-blocking layer is 5 mm, and the outer diameter is 12 mm;

[0071] (3) Mix the following materials to obtain the raw material mixture of the lens body: hydroxyethyl methacrylate 98.1wt.%, ethylene glycol dimethacrylate 0.5wt.%, UV416 ultraviolet absorber 1wt.%, C.I. reactive blue 40.05 wt.%, reactive yellow 860.05wt.% and azobisisobutyronitrile 0.0.3wt.%;

[0072] (4) Inject the raw material mixtur...

Embodiment 2

[0076] (1) Mix the following materials to obtain the raw material mixture of the light blocking layer: iron oxide 3wt.%, phthalocyanine green 3wt.%, permanent violet 2.7wt.%, PDMS 30wt.%, SIGMA 30wt.%, ethylene glycol di 5wt.% of methacrylate, 10wt.% of 1-vinyl-2-pyrrolidone, 15wt.% of ethyl lactate, 1wt.% of n-dodecanethiol and 0.3wt.% of benzoyl peroxide; The viscosity of the raw material mixture of the layer is 360000mPa;

[0077] (2) Print the raw material mixture of the light-blocking layer on the upper mold of the mould, the inner diameter of the ring of the light-blocking layer printed is 8mm, and the outer diameter is 12mm;

[0078] (3) Mix the following materials to obtain the raw material mixture of the lens body: PDMS 46wt.%, SIGMA 38wt.%, ethylene glycol dimethacrylate 4.6wt.%, 1-vinyl-2-pyrrolidone 10wt.%, UV416 UV absorber 1wt.%, C.I. reactive blue 40.1wt.% and azobisisobutyronitrile 0.3wt.%;

[0079] (4) Inject the raw material mixture of the lens body obtaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com