Preparation method of bacteriostatic cationic nanofibrillated cellulose

A cationic and cellulose technology, applied in the field of preparation of nanofibrillated cellulose, can solve the problems of biodegradability, reduced NFC hydrophilicity, poor biosafety or environmental friendliness, etc., and achieves good thermal stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

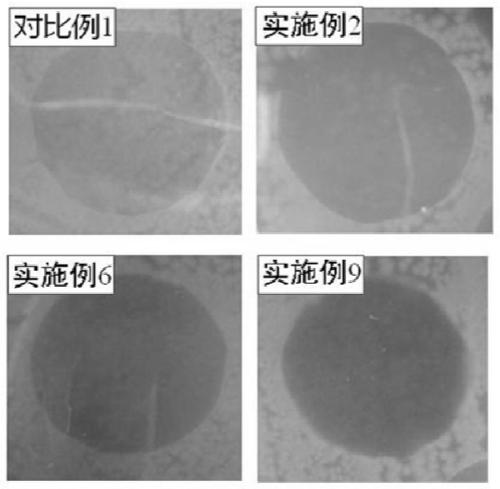

Image

Examples

Embodiment 1

[0024] The method for preparing antibacterial Q-NFC at room temperature is as follows:

[0025] Weigh 0.3g NaOH and dissolve in 6.6g bleached wet bamboo pulp with a solid content of 15wt%, stir until evenly mixed, add 1.4g 2,3-epoxypropyltrimethylammonium chloride (EPTAC), and mix well Afterwards, place it at room temperature and react for 1 hour. After the reaction is completed, disperse the slurry in deionized water, use 0.07M ethanol solution containing 4-coumaric acid to adjust the pH value of the system to neutral, and wash away unresolved impurities with deionized water. After reacting the reagents, homogenize under high pressure to obtain a uniform Q-NFC water dispersion.

Embodiment 2

[0027] The method for preparing antibacterial Q-NFC at room temperature is as follows:

[0028] Weigh 0.2g NaOH and dissolve in 3.5g solid content of 28wt% bleached wet bamboo pulp, stir until evenly mixed, add 2.9g 2,3-epoxypropyltrimethylammonium chloride (EPTAC), fully mix After homogenization, place it at room temperature to react for 1 hour. After the reaction is completed, disperse the slurry in deionized water, use 0.1M ethanol solution containing 4-coumaric acid to adjust the pH value of the system to neutral, and wash it away with deionized water. After unreacted reagents, high-pressure homogenization to obtain a uniform Q-NFC aqueous dispersion.

Embodiment 3

[0030] The method for preparing antibacterial Q-NFC at room temperature is as follows:

[0031] Weigh 0.2g NaOH and dissolve it in 3.3g of bleached wet bamboo pulp with a solid content of 30wt%, stir until evenly mixed, add 4.3g 2,3-epoxypropyltrimethylammonium chloride (EPTAC), and mix thoroughly After homogenization, place it at room temperature to react for 1 hour. After the reaction is completed, disperse the slurry in deionized water, use 0.1M ethanol solution containing 4-coumaric acid to adjust the pH value of the system to neutral, and wash it away with deionized water. After unreacted reagents, high-pressure homogenization to obtain a uniform Q-NFC aqueous dispersion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com