Multi-element catalytic iron-carbon microelectrode filler using rare earth tailings as raw material and its preparation method and application

A rare earth tailings, catalytic iron-carbon technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, oxidized water/sewage treatment, etc., can solve the problem of small specific surface area of active fillers on the surface of raw materials, affecting the reaction efficiency of fillers, oxidation Reduce the problem of low potential difference, achieve the effect of saving resources, responding quickly and thoroughly, and reducing the amount of dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

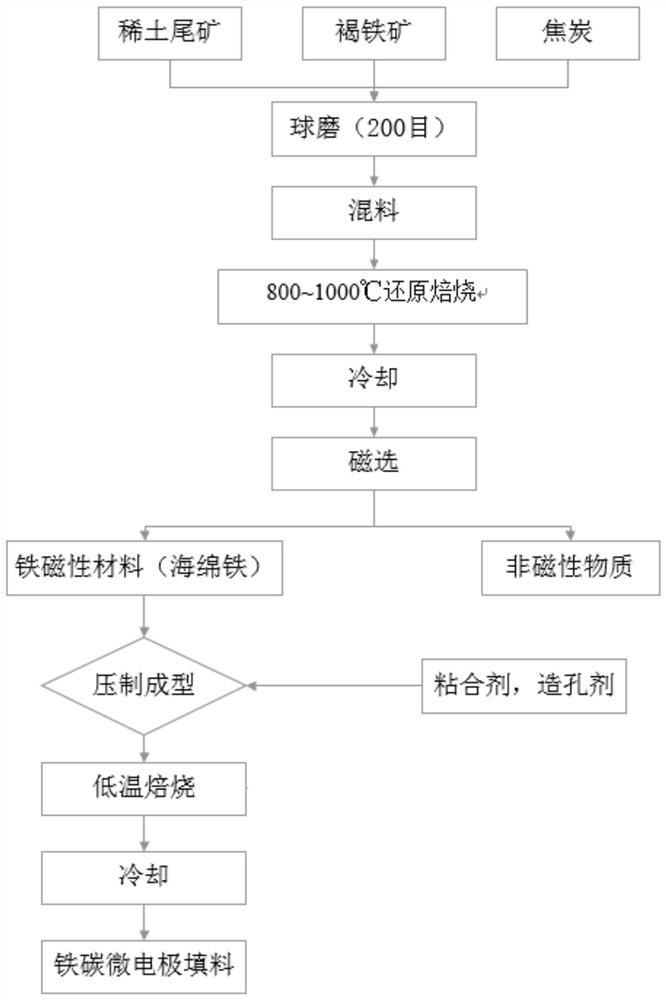

[0027] In addition, for the multi-component catalytic iron-carbon microelectrode filler of the present invention, the applicant provides a preparation method specifically, such as figure 1 shown, including the following steps:

[0028] S1: Put the rare earth tailings, limonite and coke into a ball mill for ball milling, and then pass through a 200-mesh sieve.

[0029] S2: Mix the rare earth tailings, limonite and coke after ball milling and sieving in proportion, then reduce and roast at 800-1000°C for 1-3 hours, and cool after roasting.

[0030] S3: Magnetic separation is performed on the reduced and roasted samples to obtain ferromagnetic materials (sponge iron) and non-magnetic materials, respectively.

[0031] S4: Add binder and porogen to the ferromagnetic material (sponge iron), mix and stir evenly, then press and form spherical particles with a diameter of 8-10cm, and then gradually heat up at a speed of 3-5°C / min To 70 ~ 80 ℃, and then continue to dry for 20min.

[...

Embodiment 1

[0040] This implementation provides a method for preparing multi-component catalytic iron-carbon microelectrode fillers by using rare earth tailings, including the following steps:

[0041] S1: Mix 35g of rare earth tailings, 30g of limonite and 75g of coke, perform ball milling, and pass through a 200-mesh sieve.

[0042] S2: The rare earth tailings, limonite and coke that have been sieved by the ball mill are uniformly mixed in a mixing box, and then reduced and roasted at 1000°C.

[0043] S3: performing magnetic separation on the reduced and roasted samples to obtain ferromagnetic materials and nonmagnetic materials respectively.

[0044] S4: Add 40g of kaolin and 15g of activated carbon to the magnetically separated Fe element, add a certain amount of water, slowly shake it to form spherical particles with a particle size of 9mm, and then put it into a muffle furnace at a speed of 3°C / min Gradually raise the temperature to 80°C, continue drying for 20 minutes, and evapora...

Embodiment 2

[0048] This implementation provides a method for preparing multi-component catalytic iron-carbon microelectrode fillers by using rare earth tailings, including the following steps:

[0049] S1: Mix 35g of rare earth tailings, 30g of limonite and 75g of coke, perform ball milling, and pass through a 200-mesh sieve.

[0050] S2: The rare earth tailings, limonite and coke that have been sieved by the ball mill are uniformly mixed in a mixing box, and then reduced and roasted at 900°C.

[0051] S3: performing magnetic separation on the reduced and roasted samples to obtain ferromagnetic materials and nonmagnetic materials respectively.

[0052] S4: Add 40g of kaolin and 15g of activated carbon to the magnetically separated Fe element, add a certain amount of water, slowly shake it to form spherical particles with a particle size of 8mm, and then put it into a muffle furnace at a speed of 5°C / min Gradually raise the temperature to 70°C, continue drying for 20 minutes, and evaporat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com