Preparation method of visible light response high-efficiency composite photocatalyst g-C3N4/alpha-FeOOH/Ag

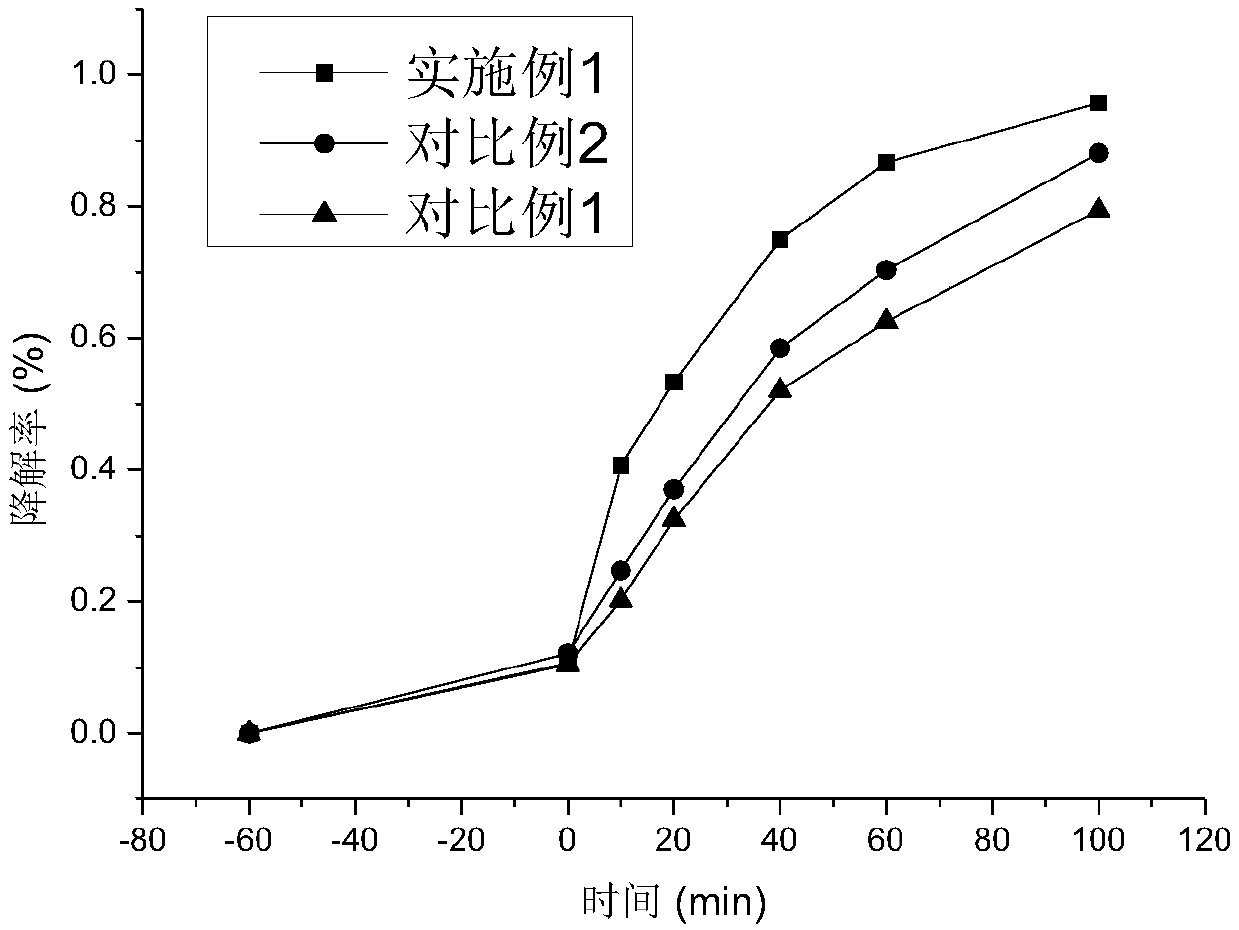

A technology of g-c3n4 and composite light, which is applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problem of low reduction ability of photogenerated electrons, low photocatalytic activity, and difficult separation of electrons and holes and other problems, to achieve the effect of facilitating degradation, high photocatalytic activity, and improving photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] High-efficiency composite photocatalyst g-C responsive to visible light of the present invention 3 N 4 The preparation method of / α-FeOOH / Ag, comprises the steps:

[0031] 1) Mechanical grinding: Weigh 0.1g of α-FeOOH nanoparticles and 0.8g of g-C 3 N 4 Nanoparticles (by mass ratio α-FeOOH nanoparticles: g-C 3 N 4 Nanoparticles = 1:8) Grind in an agate mortar for 5 minutes to fully compound the two materials and form g-C 3 N 4 / α-FeOOH composite solid material;

[0032] 2) Photorecombination: Take 0.4g of g-C obtained in the above step 1) 3 N 4 / α-FeOOH composite solid material in a beaker, add 50ml deionized water, then add 0.01gAgNO 3 Powder (AgNO 3 powder with g-C 3 N 4 / α-FeOOH solid composite material with a mass ratio of 1:40), stirred for 90min under visible light conditions and then separated from solid to liquid to obtain a solid phase;

[0033] 3) Drying and grinding: Dry the solid phase obtained in step 2) at 70°C for 10 hours, and finally grind...

Embodiment 2

[0037] High-efficiency composite photocatalyst g-C responsive to visible light of the present invention 3 N 4 The preparation method of / α-FeOOH / Ag, comprises the steps:

[0038] 1) Mechanical grinding: Weigh 0.1g of α-FeOOH nanoparticles and 0.2g of g-C 3 N 4 Nanoparticles (by mass ratio α-FeOOH nanoparticles: g-C 3 N 4 Nanoparticles = 1:2) Grind in an agate mortar for 10 minutes to fully compound the two materials and form g-C 3 N 4 / α-FeOOH composite solid material;

[0039] 2) Photorecombination: take 0.5g of g-C obtained in the above step 1) 3 N 4 / α-FeOOH composite solid material in a beaker, add 60ml deionized water, then add 0.01gAgNO 3 Powder (AgNO 3 powder with g-C 3 N 4 The mass ratio of / α-FeOOH solid composite material is 1:50), using a xenon lamp as the light source, the light wavelength range is 400nm, stirring under light conditions for 90-120min and then undergoing solid-liquid separation to obtain a solid phase;

[0040] 3) Drying and grinding: ...

Embodiment 3

[0044] High-efficiency composite photocatalyst g-C responsive to visible light of the present invention 3 N 4 The preparation method of / α-FeOOH / Ag, comprises the steps:

[0045] 1) Mechanical grinding: Weigh 0.1g of α-FeOOH nanoparticles and 0.6g of g-C 3 N 4 Nanoparticles (by mass ratio α-FeOOH nanoparticles: g-C 3 N 4 Nanoparticles = 1:6) Grind in an agate mortar for 10 minutes to fully compound the two materials and form g-C 3 N 4 / α-FeOOH composite solid material;

[0046] 2) Photorecombination: Take 0.6g of g-C obtained in the above step 1) 3 N 4 / α-FeOOH composite solid material in a beaker, add 80ml deionized water, then add 0.01gAgNO 3 Powder (AgNO 3 powder with g-C 3 N 4 The mass ratio of / α-FeOOH solid composite material is 1:60), using a xenon lamp as the light source, the light wavelength range is 800nm, stirring for 120min under light conditions and then undergoing solid-liquid separation to obtain a solid phase;

[0047] 3) Drying and grinding: Dry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| band gap | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com