Doped graphene material and preparation method and application thereof

A nitrogen-doped graphene and graphite material technology, applied in the field of materials, can solve the problems of graphene sheet thickness, high oxygen content, and low graphene yield, and achieve thin graphene sheets, low oxygen content, and yield high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

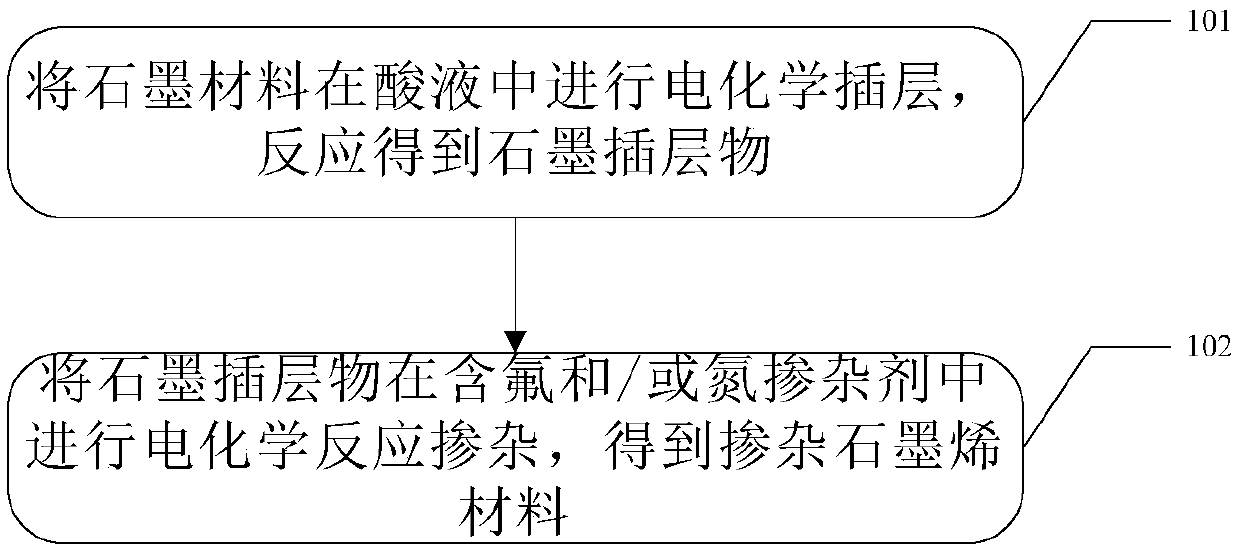

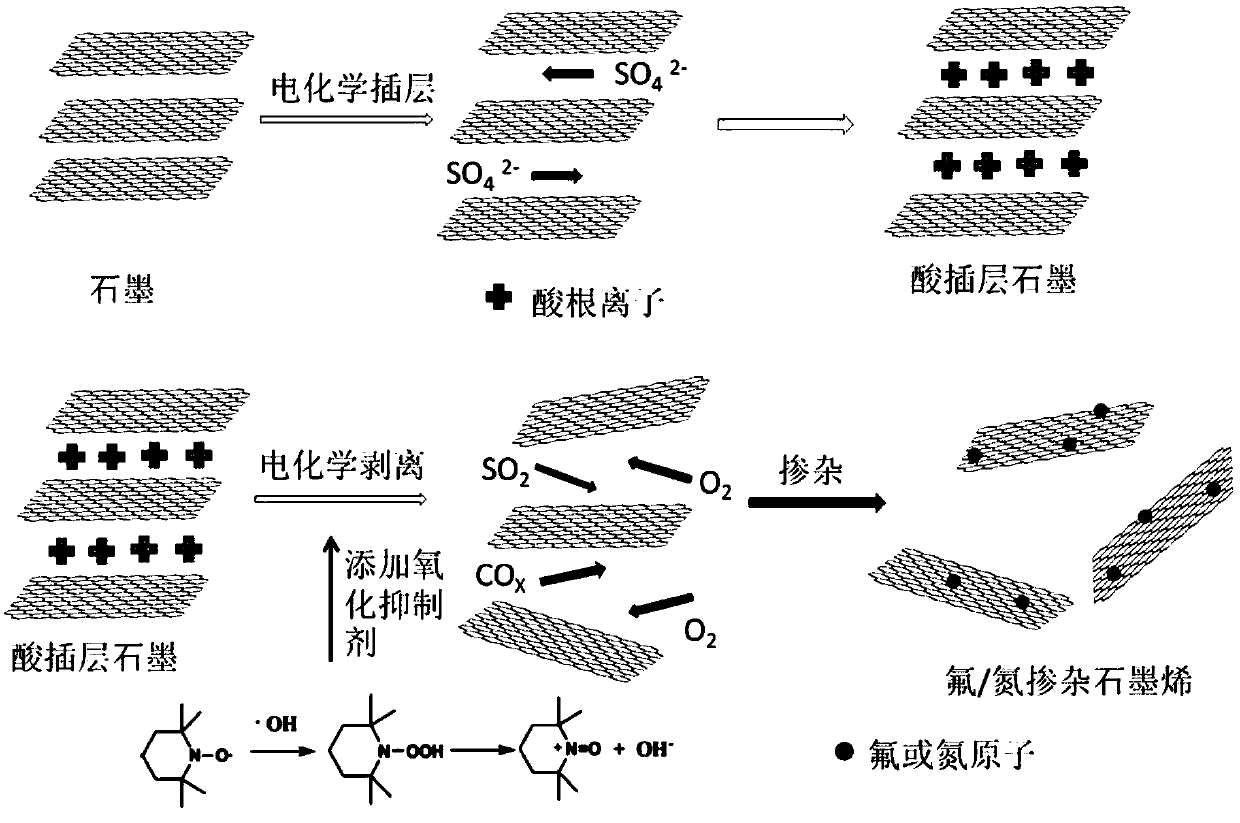

[0029] see figure 1 and figure 2 The embodiment of the present invention provides a method for preparing a doped graphene material, including: step 101, electrochemically intercalating the graphite material in an acid solution, and reacting to obtain a graphite intercalation product. Step 102, electrochemically doping the graphite intercalation in fluorine- and / or nitrogen-containing dopants to obtain a doped graphene material.

[0030] In the method provided by the embodiments of the present invention, when preparing a doped graphene material, electrochemical intercalation is first performed to obtain a graphite intercalation, and then doped by an electrochemical reaction to obtain a doped graphene material, which has graphite The graphene layer is thin, the oxygen content is low, the conductivity is high, the water dispersibility is good, and the yield of the obtained doped graphene is high, and the preparation method is simple, and it is suitable for large-scale productio...

Embodiment 1

[0052] A preparation method of doped graphene material, comprising the steps of:

[0053] Step 201: Press 500 mg of graphite powder into graphite paper, connect the graphite paper and the platinum sheet to the positive and negative electrodes of the power supply through wires, and immerse the graphite paper and the platinum sheet in concentrated sulfuric acid. Start the power supply, control the power supply voltage to 2V, and perform electrochemical intercalation with a reaction time of 30 minutes to obtain intercalated graphite. Due to the insertion of a large number of anions and co-intercalated substances into the graphite layer, the distance between the graphite layers increases, and a slight expansion of the intercalated graphite paper can be observed.

[0054] Step 202: Mix urea, 2,2,6,6-tetramethylpiperidine-1-oxyl radical, and ammonium sulfate to make an electrolyte solution. After mixing, the urea in the electrolyte solution is 0.5mol / L, 2,2, 6,6-tetramethylpiperidi...

Embodiment 2

[0064] A preparation method of doped graphene material, comprising the steps of:

[0065] Step 301: Pressing 1g of flake graphite into a graphite rod; mixing concentrated sulfuric acid and glacial acetic acid at a volume ratio of 6:4 to obtain a mixed electrolyte, connecting the graphite rod and the platinum sheet to the positive and negative electrodes of the power supply through wires, and Graphite paper and platinum flakes are immersed in the mixed electrolyte. Start the power supply, control the power supply voltage to 3V for electrochemical intercalation, and the reaction time is 30 minutes to obtain intercalated graphite rods.

[0066] Step 302: Melamine, NaBH 4 , ammonium sulfate mixed to make an electrolyte, the melamine in the electrolyte after mixing is 1mol / L, NaBH 4 2mg / mL, ammonium sulfate 0.1mol / L. The intercalated graphite rod and the platinum sheet are respectively connected to the positive and negative electrodes of the power supply through wires, and the i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com