Manipulator desertion device for manned submersible

A manned submersible, manipulator technology, applied in motor vehicles, underwater ships, transportation and packaging, etc., can solve the increase in installation and maintenance workload and time, cannot take into account the requirements of seawater anti-corrosion, and the weight of the manipulator discarding device is too heavy and other problems, to achieve the effect of improving maintenance and guarantee efficiency, abandoning efficiency and reliability, and reducing personnel maintenance and guarantee time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

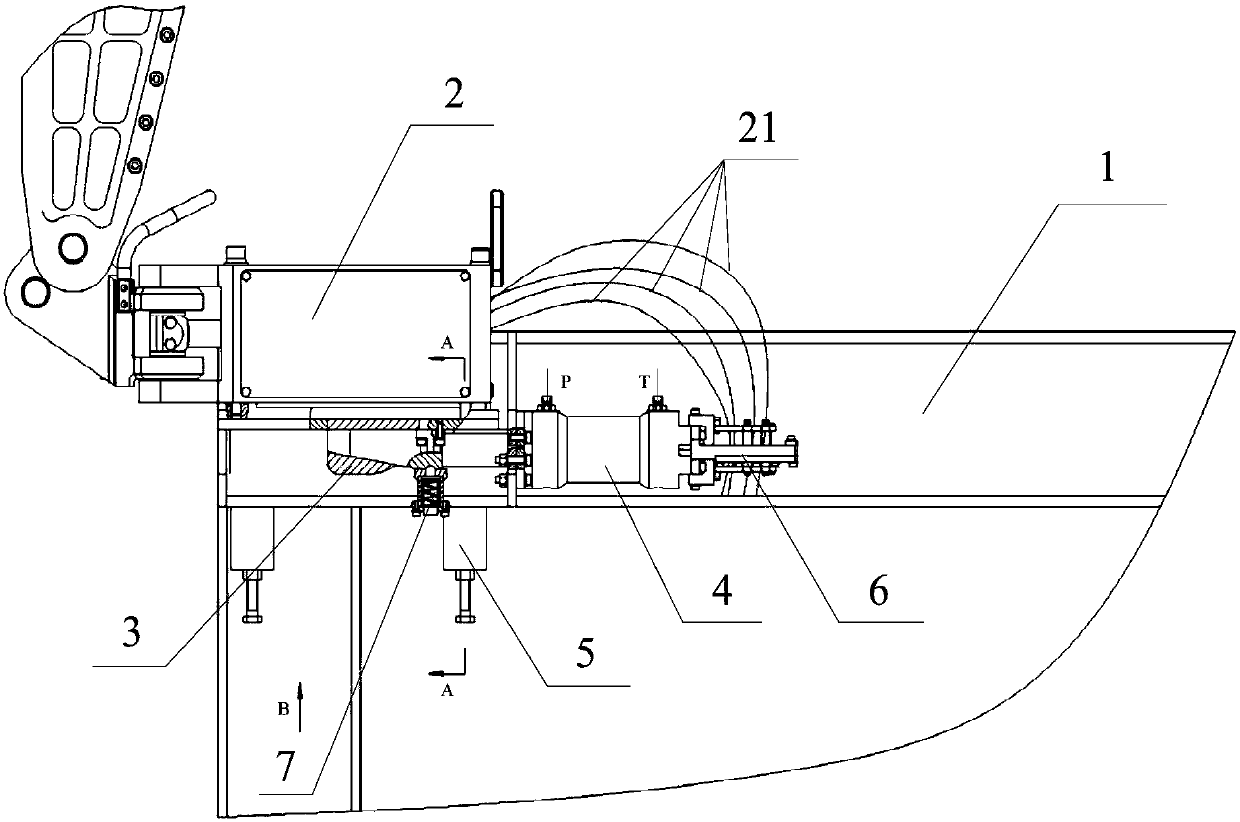

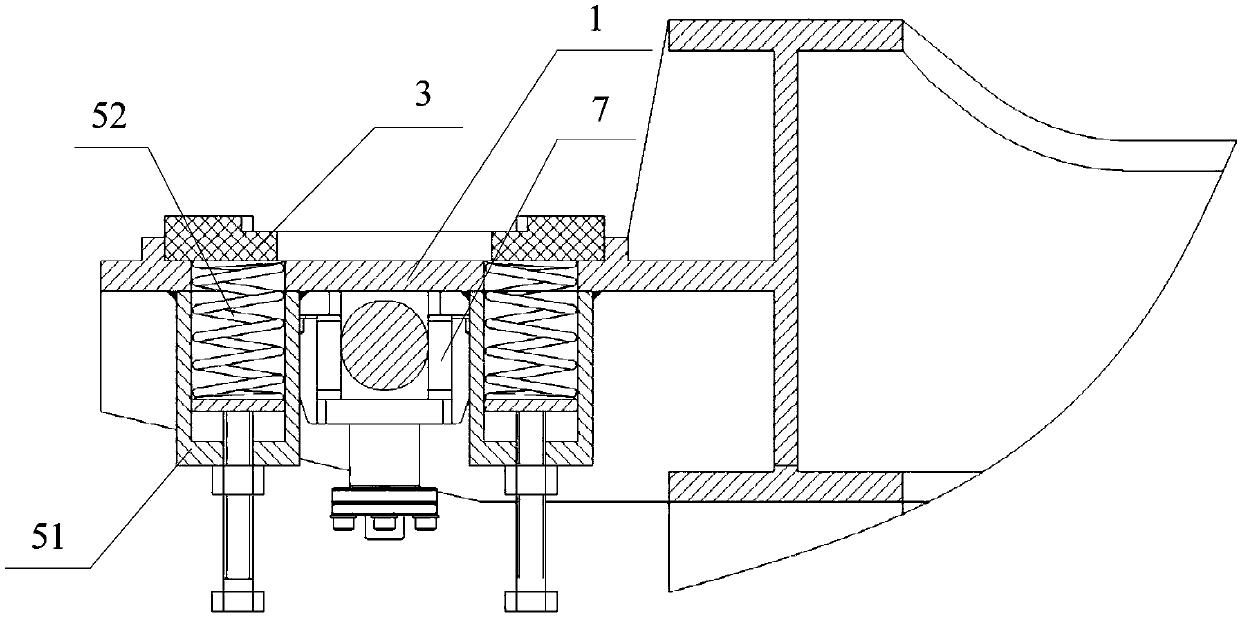

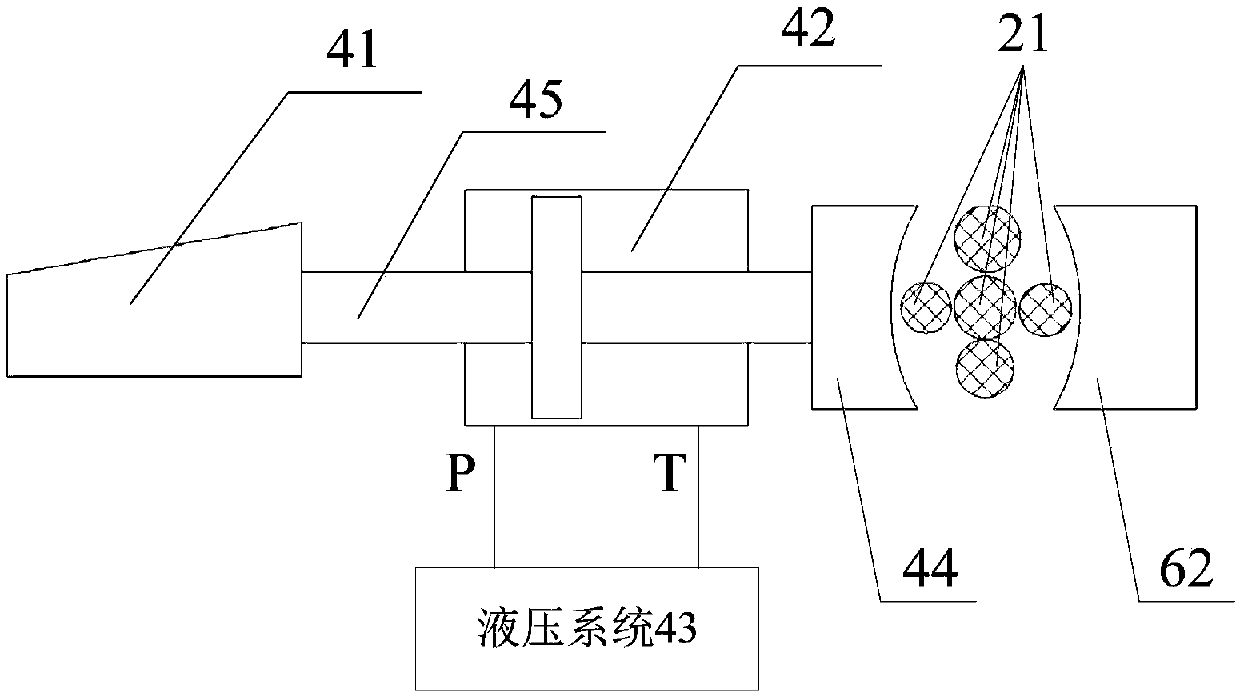

[0026] This application discloses a manipulator discarding device for a manned submersible, which includes a submersible frame 1 and a manipulator 2 of the manned submersible. For discarding, please refer to figure 1 As shown in the structural diagram, the discarding device of the manipulator includes a bottom plate 3 , a discarding cutting assembly 4 , an overturning assembly 5 and a piping protection assembly 6 . The bottom plate 3, the jettison cutting assembly 4 and the piping protection assembly 6 are sequentially arranged on the submersible frame 1 and located on the same axis. The submersible frame 1 is provided with a frame opening, the shape of the bottom plate 3 matches the shape of the frame opening, and the bottom plate 3 is arranged in the frame opening. In this application, the top of the bottom plate 3 is a flat plate struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com