Milling machining device

A milling processing and equipment technology, applied in metal processing equipment, grinding/polishing equipment, grinding workpiece supports, etc., can solve the problems of difficult control of grinding amount and large labor input, and achieve the effect of reducing labor input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following is further described in detail through specific implementation methods:

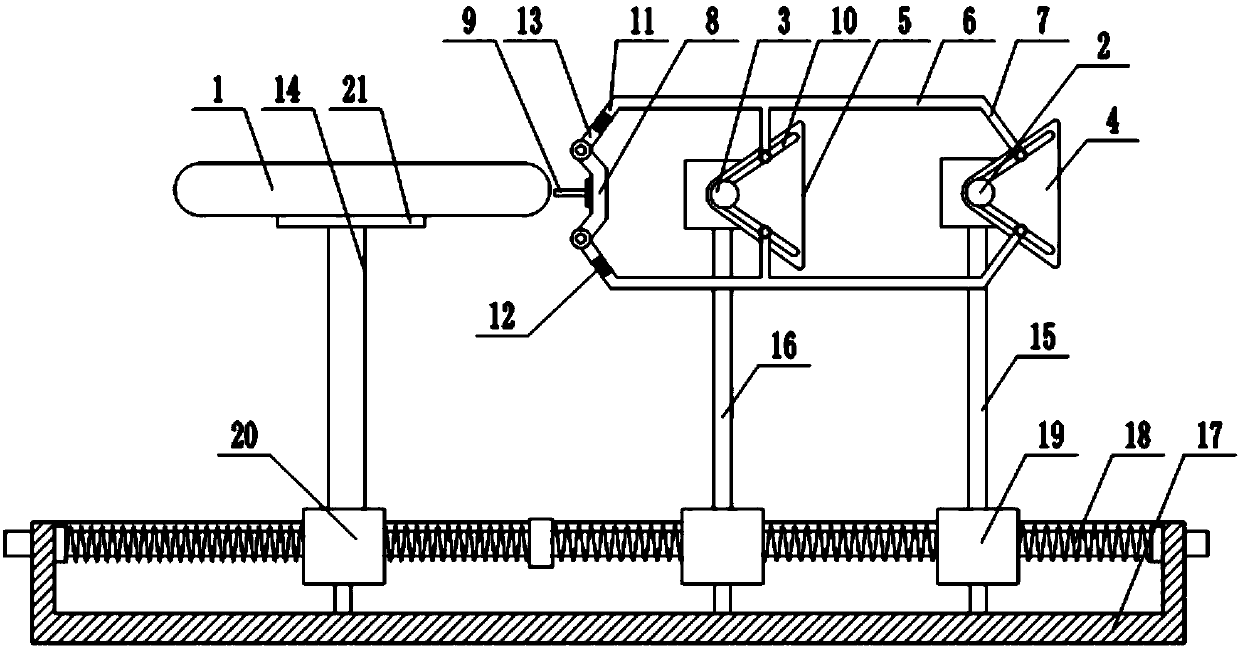

[0022] The reference signs in the drawings of the specification include: workpiece 1, first rotating shaft 2, second rotating shaft 3, first fixing seat 4, second fixing seat 5, bending rod 6, bending part 7, grinding seat 8, grinding Head 9, adjustment groove 10, first threaded cylinder 11, adjustment screw 12, second threaded cylinder 13, drive shaft 14, first pole 15, second pole 16, fixed groove 17, two-way screw rod 18, the first A nut 19, a second nut 20, a fixed plate 21, an arc block 22, and a telescopic rod 23.

[0023] The embodiment is basically as attached figure 1 Shown: milling processing equipment, comprise fixed groove 17, in the fixed groove 17 horizontal rotation is connected with two-way screw rod 18, the two ends of two-way screw rod 18 respectively pass through the left and right side walls of fixed groove 17, the two-way screw rod 18 The left end is coaxially ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com