A Radial Ultrasonic Vibration Lens Assisted Laser Processing Device

An ultrasonic vibration and auxiliary laser technology, applied in metal processing equipment, laser welding equipment, manufacturing tools, etc., can solve the problems of no laser focus measurement method, high requirements for laser overlap rate, and inability to guarantee processing quality, etc. The effect of overlapping ratio, improved surface quality and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

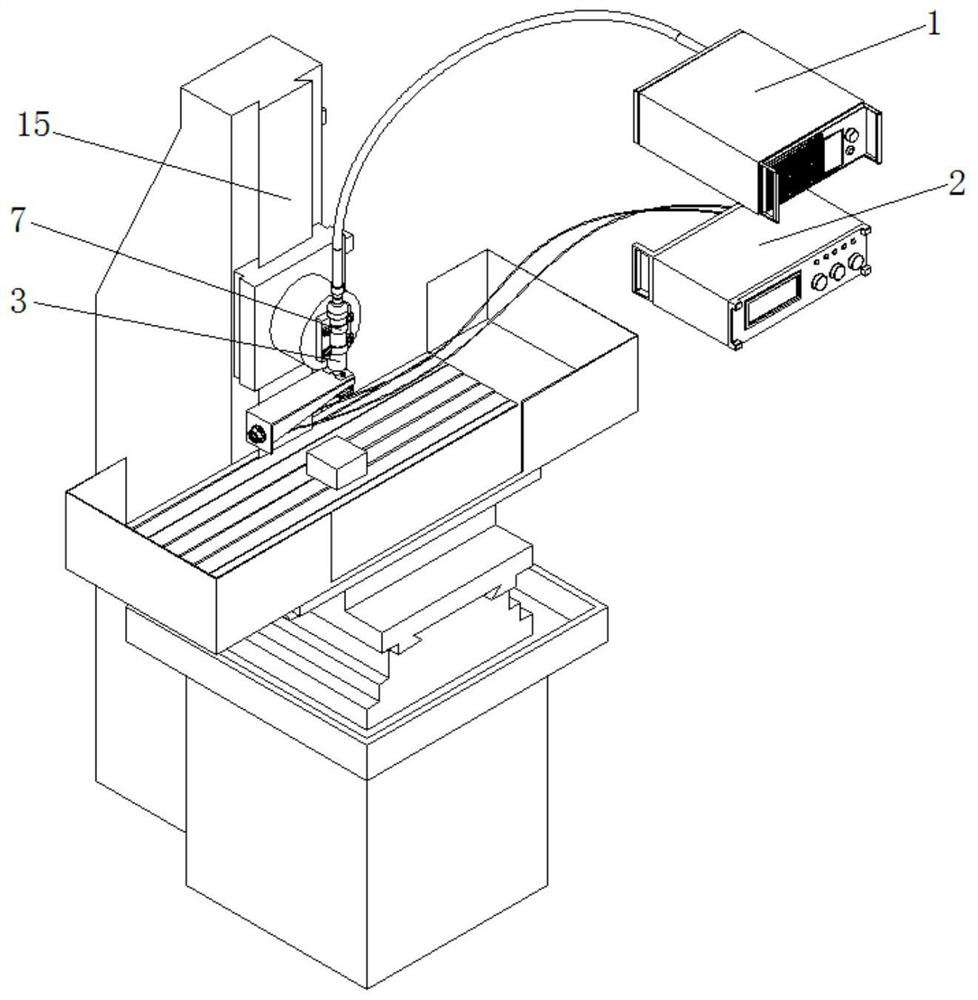

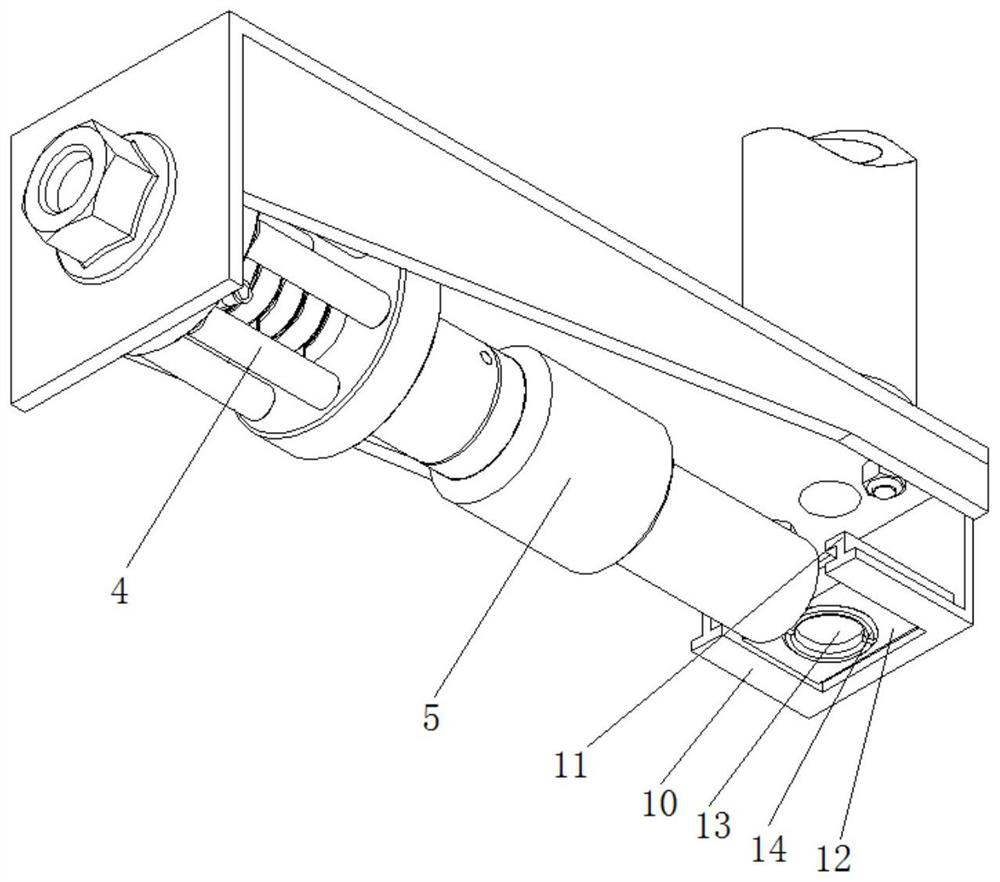

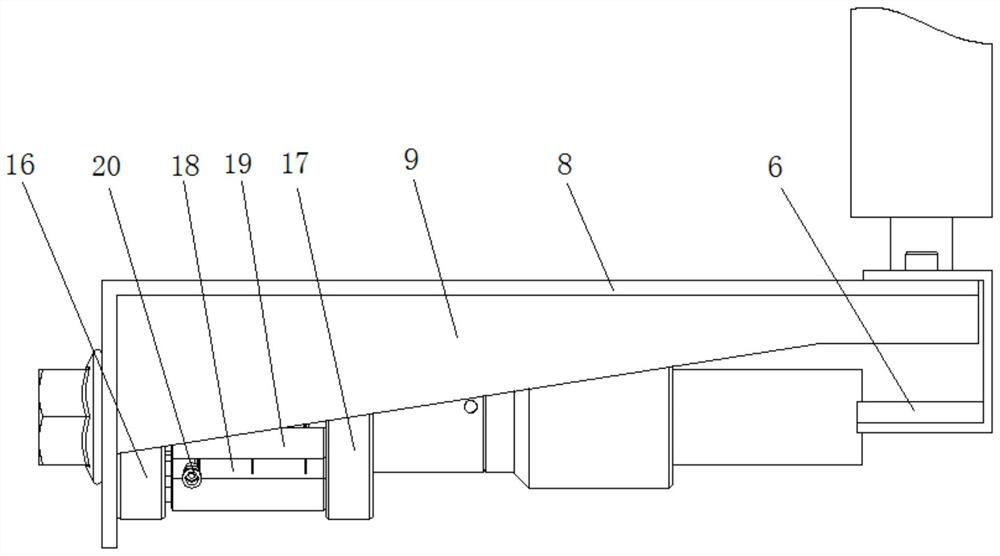

[0022] Such as Figure 1-4 As described above, a radial ultrasonic vibrating lens-assisted laser processing device includes a laser generator 1 and an ultrasonic generator 2, and the output end of the laser generator 1 is connected to one end of the collimating mirror 3 of the laser working head through an optical fiber terminal. The laser working head includes a collimating mirror 3, an ultrasonic transducer 4, a horn 5, a focusing lens mechanism 6 and a fixing frame. On the main shaft 15, the fixed frame includes a fixed frame connecting plate 8, and one end of the horizontal plate of the fixed frame connecting plate 8 is fixedly installed with the other end of the collimator mirror 3 through threads, and the fixed frame connecting plate 8 is vertically arranged with the collimating mirror 3, and fixed The vertical plate at the other end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com