Heat collecting pipe rotary type grooved light condensed heat collecting system

A technology of concentrating heat and heat collecting tubes, applied in the field of solar thermal utilization, can solve the problems of cost increase, bending failure, overheating of heat collecting tubes, etc., and achieve the effect of avoiding bending failure and changing energy distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

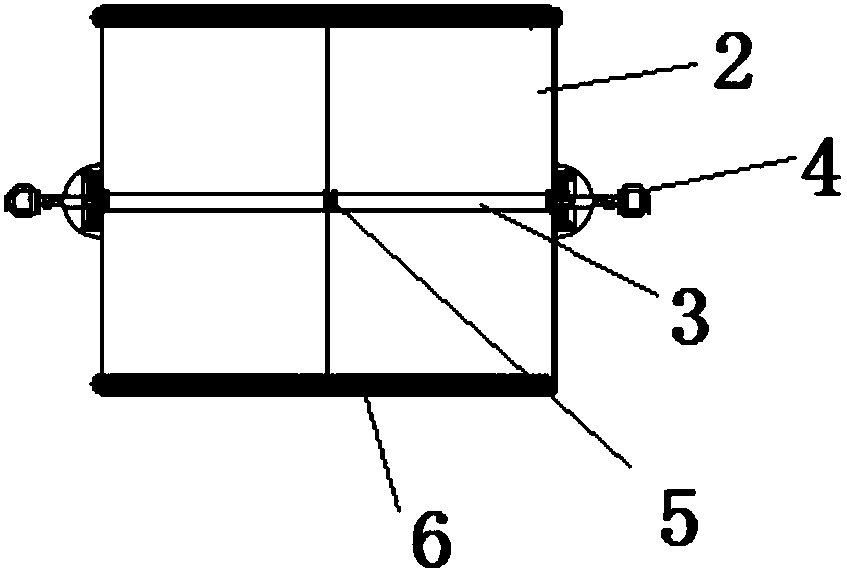

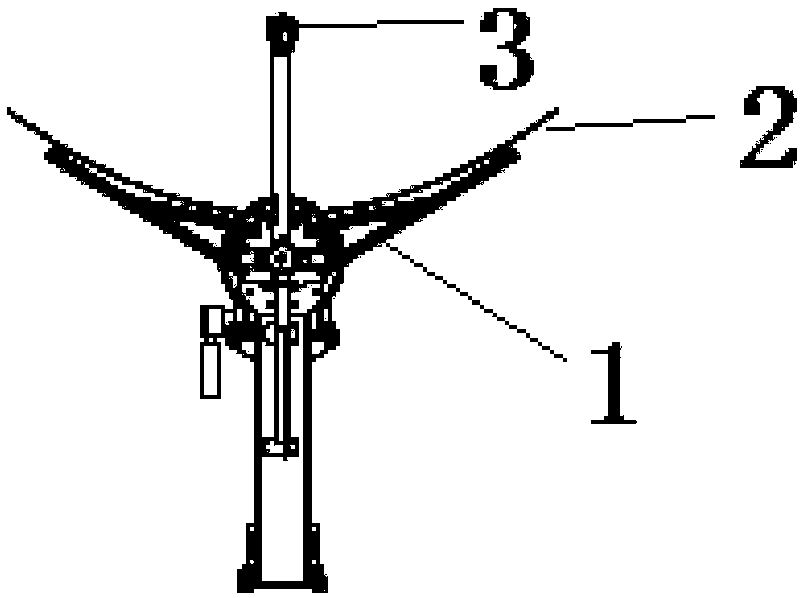

[0011] The present invention provides a trough-type light concentrating and heat-collecting system with rotating heat-collecting tubes. The structure of the system of the present invention will be further described below in conjunction with the accompanying drawings.

[0012] figure 1 and figure 2 It is a schematic diagram of a heat collecting tube rotating trough-type concentrating heat-collecting system. The concentrated heat-collecting system includes a trough bracket 1, a reflector 2, a heat collecting tube 3, a high-temperature rotary joint 4, a drive 5, and photovoltaic modules or solar energy Thin film battery 6; the heat collecting tube 3 is connected to the trough support 1 through a driving and high-temperature rotary joint, the reflector 2 is connected to the trough support 1 through bolt connection, riveting or bonding, and the photovoltaic module or solar thin film battery 6 is installed The upper and lower edges of the trough support 1 are connected with the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com