Laser cladding device based on multi-focus lens to generate preheating and slow cooling light

A multi-focus lens, laser cladding technology, applied in the direction of metal material coating process, coating, etc., can solve the problems of complex crack shape, low processing efficiency, complex processing process, etc., to reduce complexity and simple structure. , light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

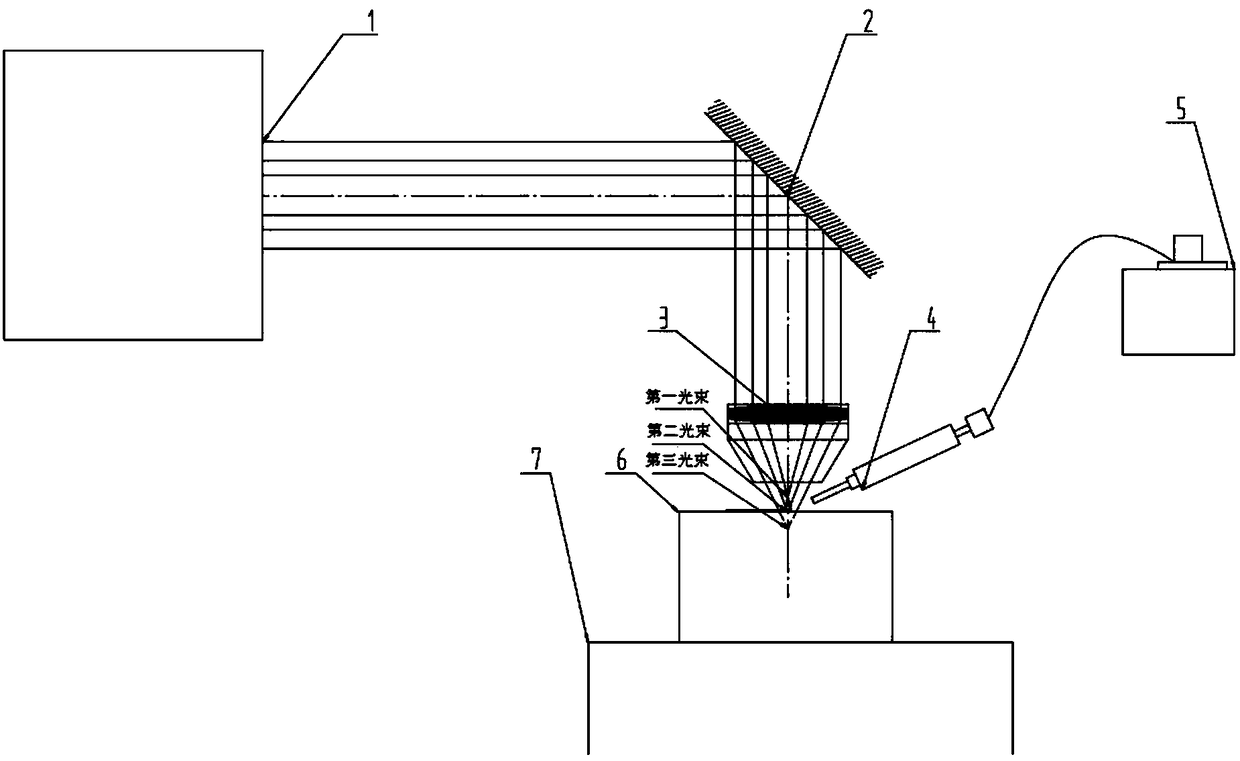

[0030] Such as figure 1 As shown, the laser cladding device based on multi-focus lens to generate preheating and slow cooling light disclosed in this embodiment includes: laser 1, mirror 2, multi-focus lens 3, side powder feeding head 4, powder feeding system 5, workpiece 6 , Workbench 7.

[0031] The laser 1 is a Nd:YAG semiconductor-pumped solid-state laser or a fiber laser with a gain medium of 1064nm, a spot diameter of 2mm, and a maximum output power of 10KW, and is used to provide a laser cladding light source.

[0032] The laser light output horizontally from the laser 1 is reflected by the mirror 2 set at 45 degrees to the horizontal laser light path, and then vertically incident on the multi-focus lens 3 . The multi-focus lens 3 is composed of a diffractive multi-focus element and a focusing mirror. The optical structure of the diffractive multi-focus element can be a zigzag blazed groove or a binary type with a rectangular waveform. It has the advantages of light we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com