A Piezoelectric Network Method for Improving the Sound Insulation Performance of Plate and Shell Structures

A technology of plate shell structure and plate structure, which is applied in the direction of transducer acoustic response prevention, etc., can solve the problems of sound insulation performance reduction, weakening, control effect dependence, etc., meet the requirements of performance reduction, improve sound insulation performance, and save work volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0036] The invention provides a piezoelectric network method for improving the sound insulation performance of a plate and shell structure. The plate and shell structure is not limited to the structure on a specific mechanical device, but generally refers to all the structures that can be attributed to plates or shells in academics. Structures such as aircraft, automobiles, submarine bulkheads, ship engine cases, and road sound insulation panels.

[0037] Taking building a piezoelectric network on a plate structure to improve its sound insulation performance as an example, the implementation steps of the present invention are specifically described below:

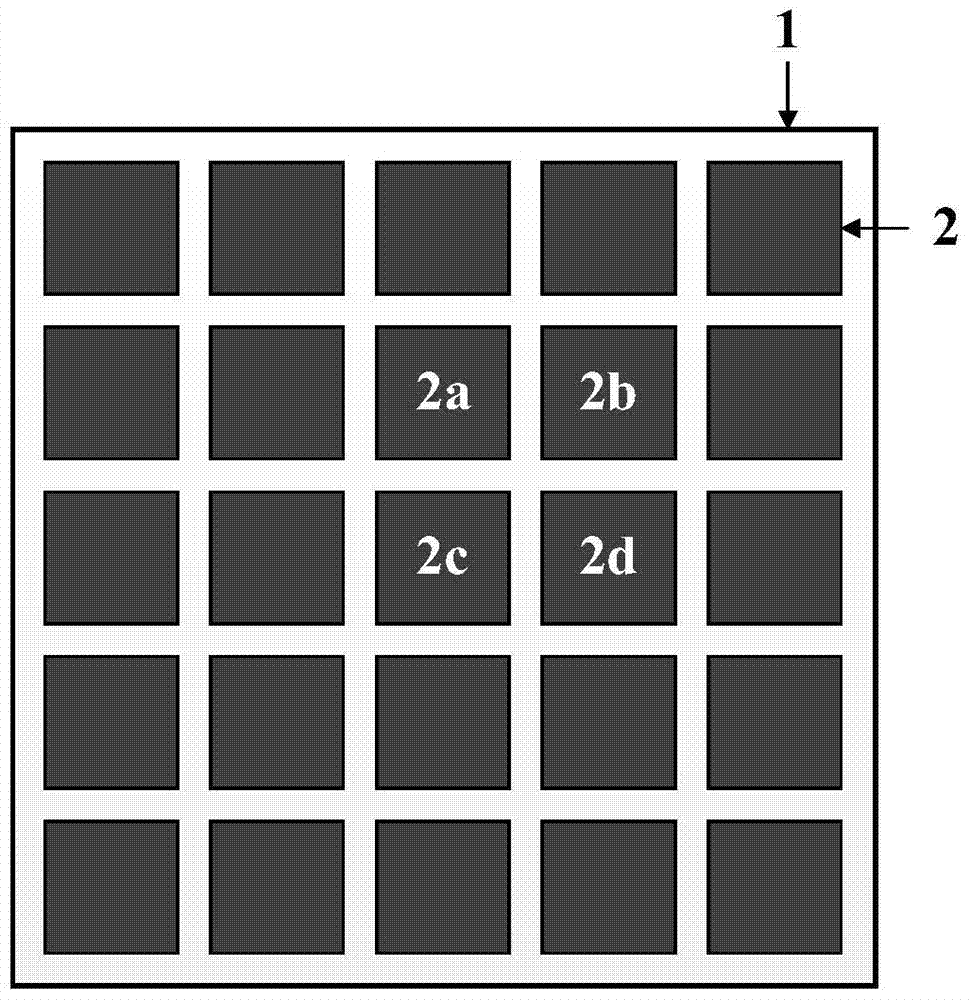

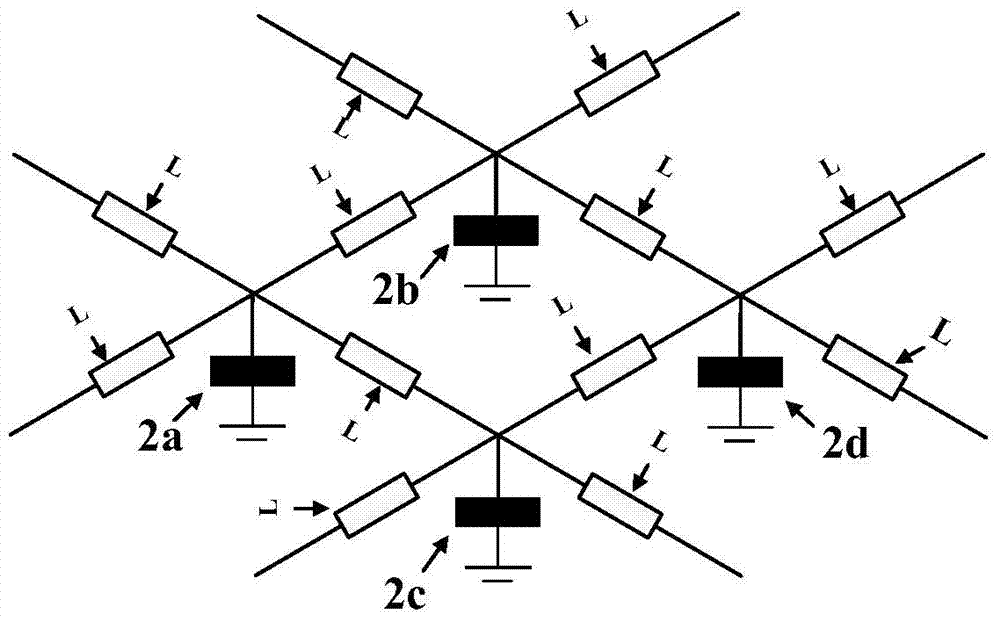

[0038] Such as figure 1 Shown:

[0039] Step 1: Evenly distribute piezoelectric actuators on the plate structure;

[0040] The piezoelectric actuator 2 can be pasted on the surface of the board structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com