A wide particle size pulsating shallow groove dense medium separator

A dense medium and sorting machine technology, applied in the field of separation, can solve the problems of unstable medium density, increase processing costs, shorten the separation time of raw coal, etc., achieve uniform medium density, prevent density changes, and improve the effect of sorting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The invention provides a sorting machine with wide particle size (higher upper limit and lower lower limit), high sorting efficiency and good energy saving effect.

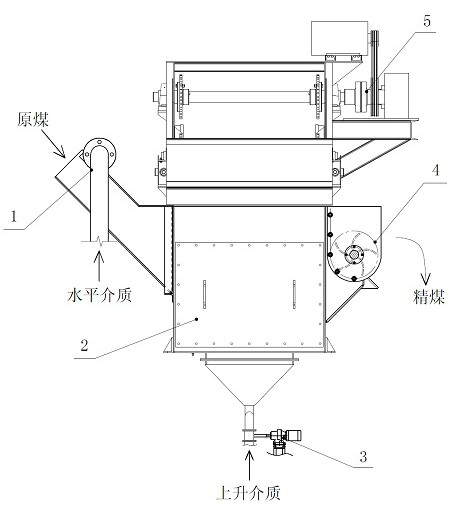

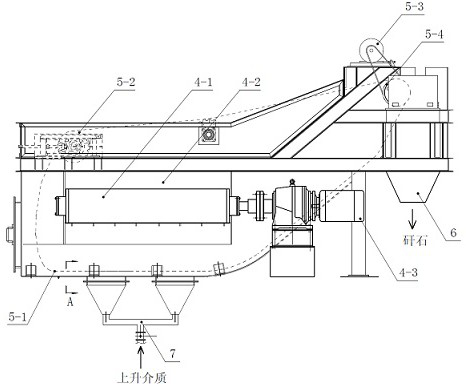

[0023] see Figure 1 ~ Figure 4 , The present invention mainly includes a coal medium mixing box 1, a sorting tank 2, a pulse valve 3, a clean coal discharge device 4 and a scraper stone discharge device 5.

[0024] The coal medium mixing box 1 includes a box body 1-1 and an inlet pipe 1-2. The box body 1-1 is a semi-closed box body, which is installed at the feeding end of the sorting tank 2 of the dense medium separator, and the raw coal and the horizontal medium The flow is fed from the upper part of the box 1-1 and the side inlet pipe 1-2 respectively. The pressure of the horizontal medium flow is relatively high. Under the action of the high-speed medium flow, the raw coal and the medium are fully stirred in the coal-mediated mixing box. Wetting ensures full contact between the medium and the raw coal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com