A single-roller crusher with a toothed nut sleeve

A nut sleeve and single-roller technology, which is used in the pretreatment field of silicon slag recovery, can solve the problems of bolts and nuts being worn, bolts and nuts cannot be taken out of the screw holes normally, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

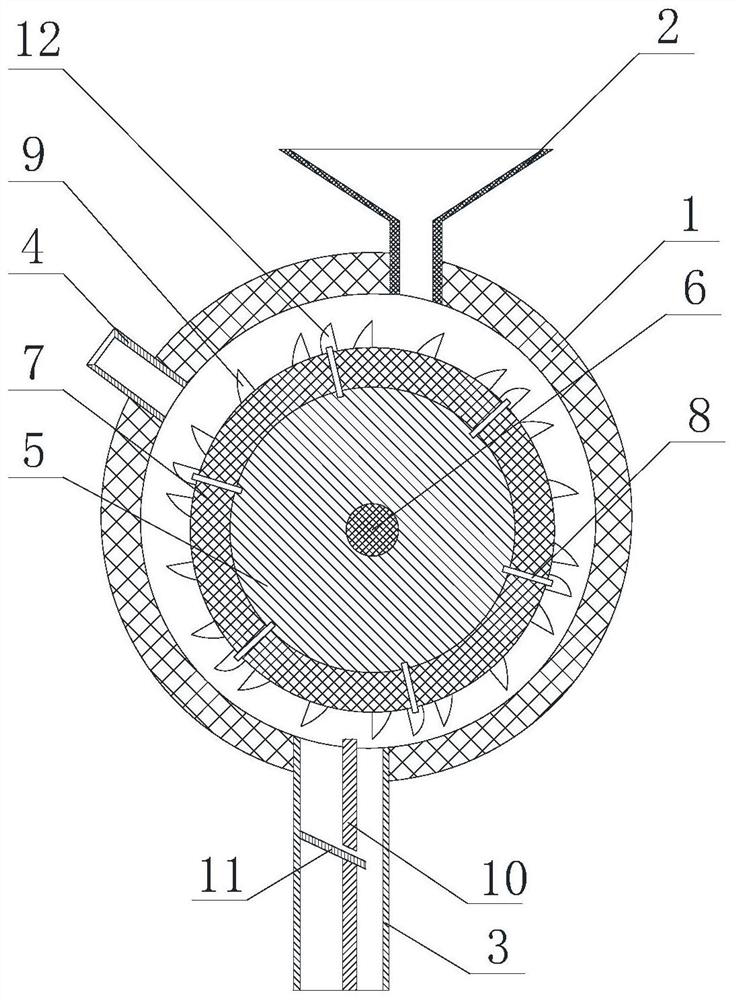

[0035] like figure 1 The shown single-roller crusher with a toothed nut cover includes a casing 1, a feed hopper 2 is arranged on the upper part of the casing 1, a discharge pipe 3 is arranged on the bottom of the casing 1, and inside the casing 1 A roller 5 is provided, and a bushing 7 is set on the outside of the roller 5, and the bushing 7 is connected with the roller 5 through a bolt 8, and the bushing 7 is provided with crushing teeth 9, and it is characterized in that the bolt 8 and the A toothed nut sleeve 12 is sheathed on the matching nut of the bolt 8 .

Embodiment 2

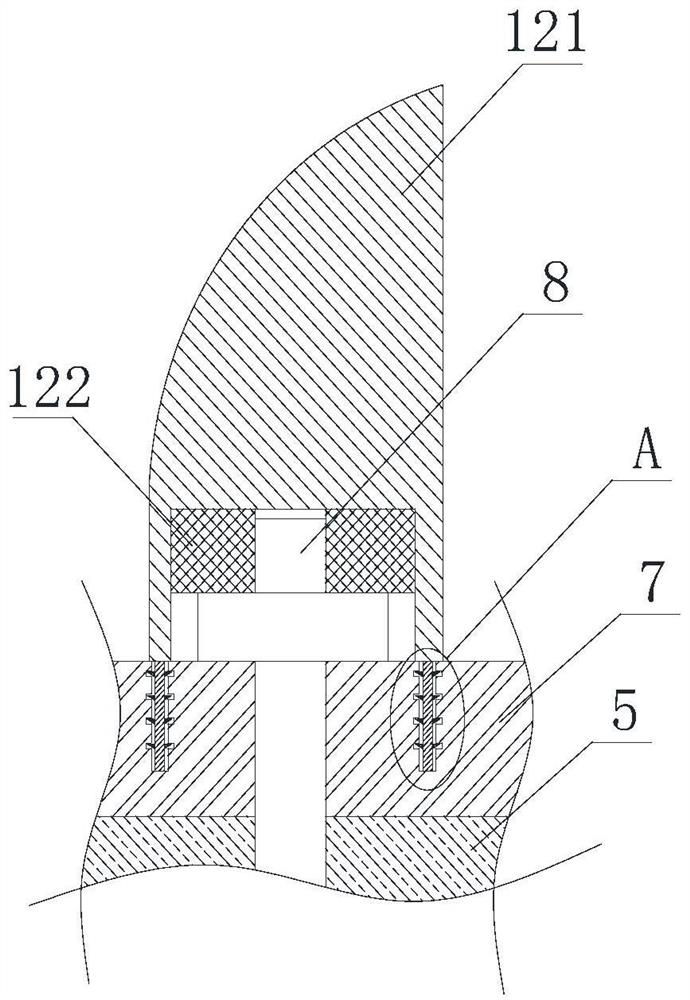

[0037] like figure 2 and image 3 As shown, on the basis of Embodiment 1, the toothed nut sleeve 12 includes a toothed cover 121, and the bottom of the toothed cover 121 is provided with an accommodating cavity, and the accommodating cavity is used to accommodate the bolt 8 on the surface of the bushing. and nuts, a snap ring 122 is arranged in the housing chamber, the inner wall of the snap ring 122 squeezes the outer surface of the bolt 8, and the outer wall of the snap ring 122 squeezes the wall surface of the housing chamber; the snap ring 122 is formed by a Made of nitrile rubber.

Embodiment 3

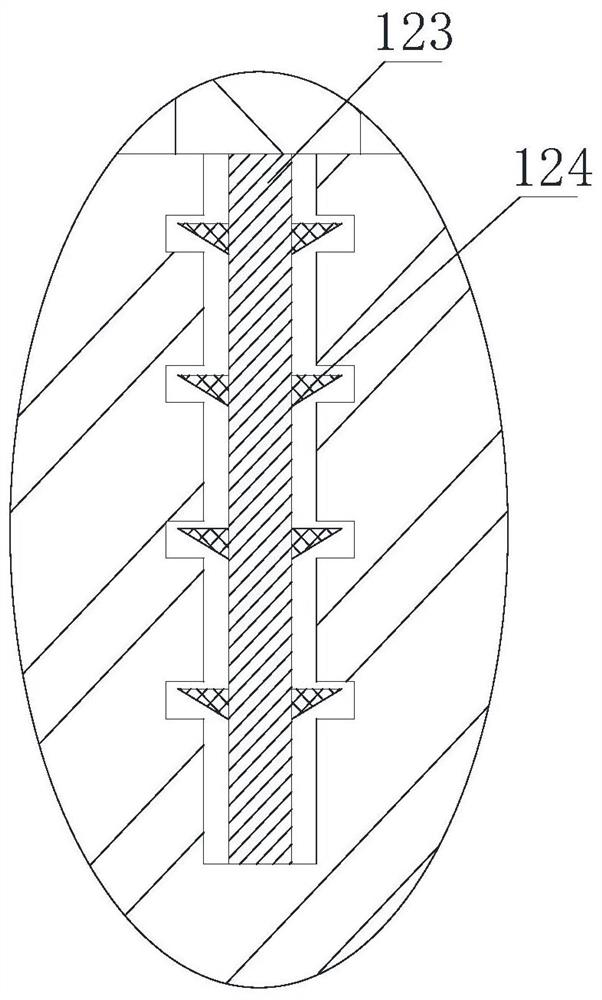

[0039] On the basis of Embodiment 2, the bottom end of the toothed cover 121 is provided with a clamping rod 123, and the bushing 7 is provided with a clamping groove, and the size of the clamping rod 123 matches the clamping groove; The side wall of the clamping groove is provided with a rectangular groove, and the clamping rod 123 is provided with an engaging tooth 124, and the rectangular groove is used to accommodate the engaging tooth 124; the cross section of the engaging tooth 124 is a right triangle, and the right angle The hypotenuse of the triangle faces downward; the number of the clamping rods 123 is four; the engaging teeth 124 are made of rubber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com