Device for directly synthesizing C1-C4 alcohol by CH4/CO2 at low temperature and synthesis method thereof

A C1-C4, CO2 technology, applied in the direction of chemical instruments and methods, chemical/physical processes, chemical/physical/physical chemical processes, etc., can solve the problems such as no alcohol, to avoid sintering and carbon deposition deactivation, The effect of high stability and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

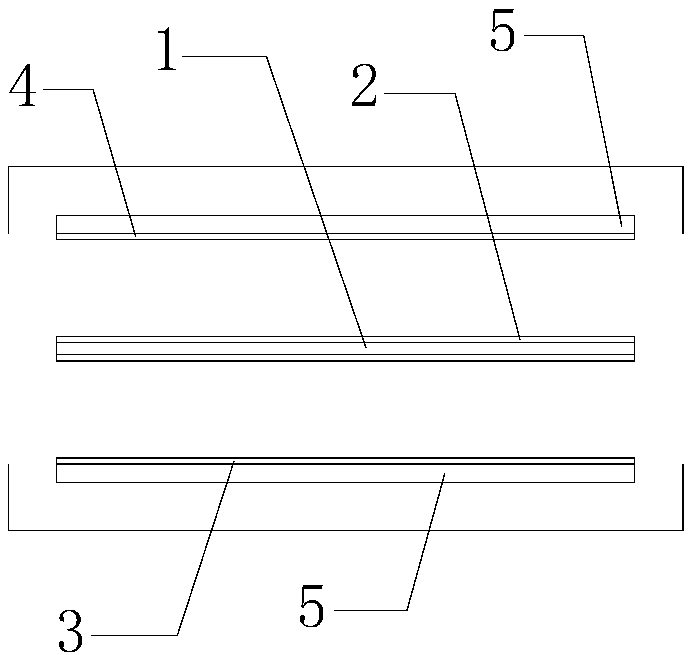

[0055] One CH 4 / CO 2 A device for directly synthesizing C1-C4 alcohols at low temperature, the device includes a 2mm thick stainless steel plate I1 as a high voltage electrode, a 2mm thick stainless steel plate II3 as a ground electrode, and a 2mm thick stainless steel plate III4 as a ground electrode;

[0056] The stainless steel plate I1 is located between the stainless steel plate II3 and the stainless steel plate III4, and the stainless steel plate II3, the stainless steel plate I1 and the stainless steel plate III4 are parallel to each other;

[0057] The upper and lower surfaces of the stainless steel plate I1 are covered with a 1mm thick glass layer 2;

[0058] The outer surface of the stainless steel plate II3 and the outer surface of the stainless steel plate III4 are in contact with the refrigeration unit 5;

[0059] The discharge distance between the stainless steel plate II3 and the stainless steel plate I1 is equal to the discharge distance between the stainless steel pla...

Embodiment 2

[0061] A CH using the device described in Example 1 4 / CO 2 A method for directly synthesizing C1-C4 alcohols at low temperature, the method is: using low-temperature plasma to selectively activate methane and carbon dioxide to generate C1-C4 alcohols;

[0062] The synthesis conditions are: the refrigeration unit 5 controls the reaction temperature to 30°C, the molar ratio of methane and carbon dioxide is 1, the residence time of methane and carbon dioxide in the plasma discharge zone is 4s, and the power input voltage is 40V, The input current is 1.00A, and the discharge frequency is 12kHz.

[0063] Conclusion: Alcohol products are detected, and it is found that low temperature is beneficial to the integration of methane dry weight into alcohols. Compared with the reaction raw materials methane and carbon dioxide, the reaction products are weaker in stability and relatively active, suggesting that low temperature inhibits the further decomposition of products, thus promoting alcoho...

Embodiment 3

[0065] The difference from Embodiment 2 is that the refrigeration unit 5 controls the reaction temperature to 90°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com