Oligonucleotide synthesis chip system and use method thereof

A technology of oligonucleotide and chip system, which is applied in the field of solid-phase chemical synthesis chip system, can solve the problems of reducing synthesis cost and chip manufacturing cost, and achieve the effects of reducing synthesis cost, low manufacturing cost and simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Embodiment 1 becomes the preparation of oligonucleotide synthesis chip

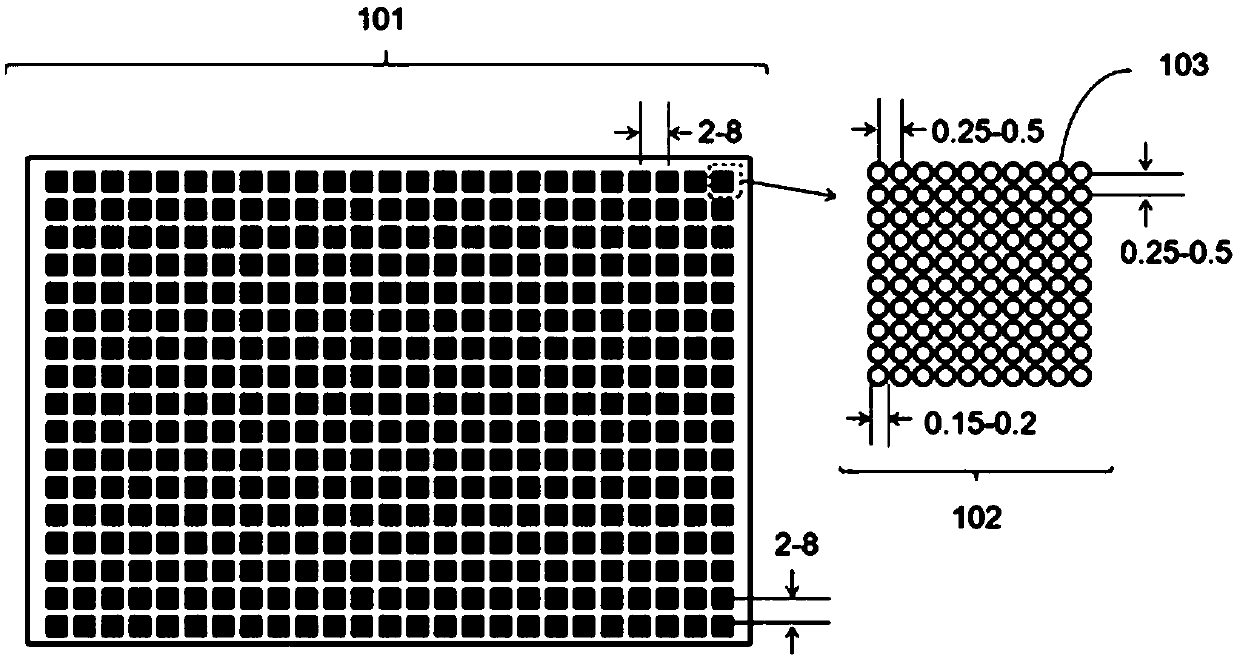

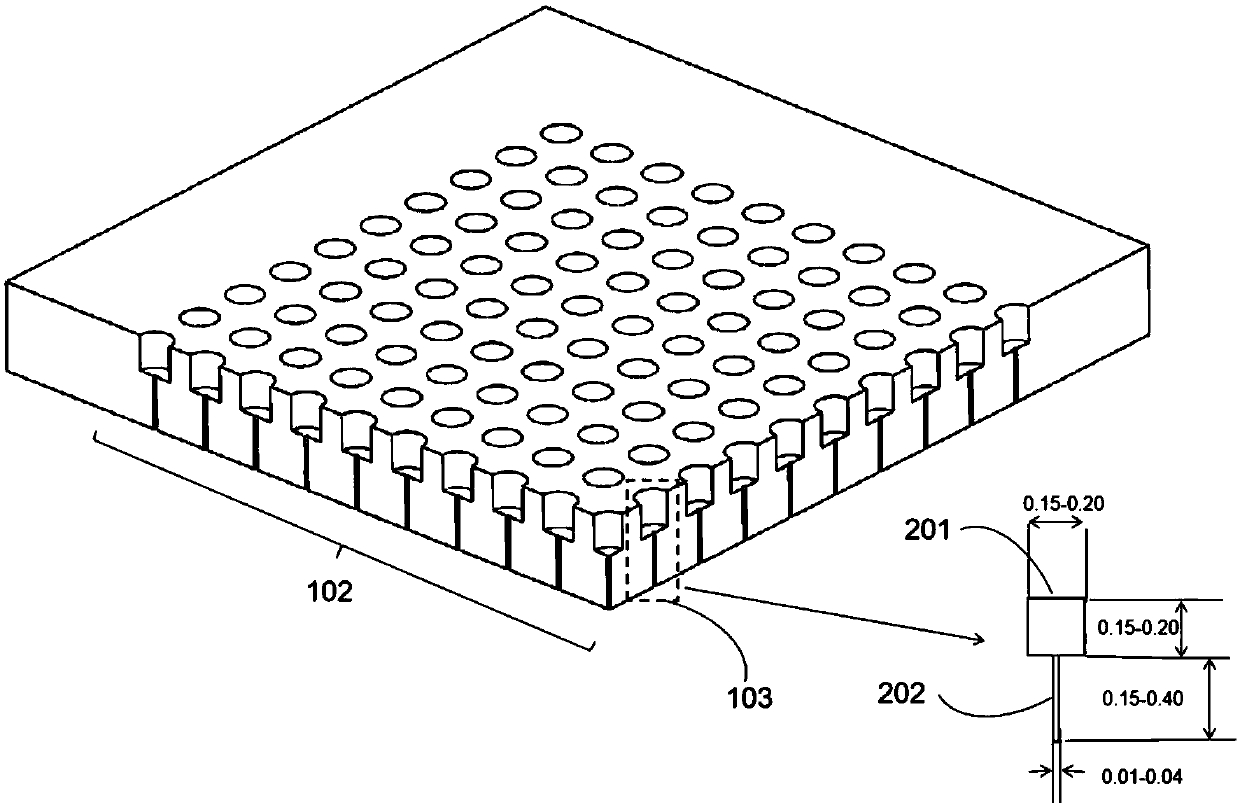

[0056] Please see attached figure 1 And attached figure 2, in this embodiment, the prepared oligonucleotide synthesis chip 101 has a length of 127 mm and a width of 85 mm, which is the same as that of a common 96-well plate. The diameter of the upper opening 201 of the micro-funnel structure 103 in the prepared oligonucleotide synthesis chip 101 is 0.15 mm, and the depth is 0.20 mm. The diameter of the lower end opening 202 is 0.02 mm, and the depth is 0.30 mm. The micro-funnel structure 103 The spacing is 0.3 mm, and the number of micro-funnel structures 103 in each group of micro-funnel structures 102 is 10×10, that is, 100. The distance between each group of micro funnel structures 102 is 3 mm.

[0057] Please see attached Figure 4 , in this embodiment, the prepared oligonucleotide synthesis chip 101 is made of silicon material, which is prepared by dry etching twice. Firstly, the photore...

Embodiment 2

[0059] Example 2 Synthetic Carrier Particle Size Screening Chip Manufacturing

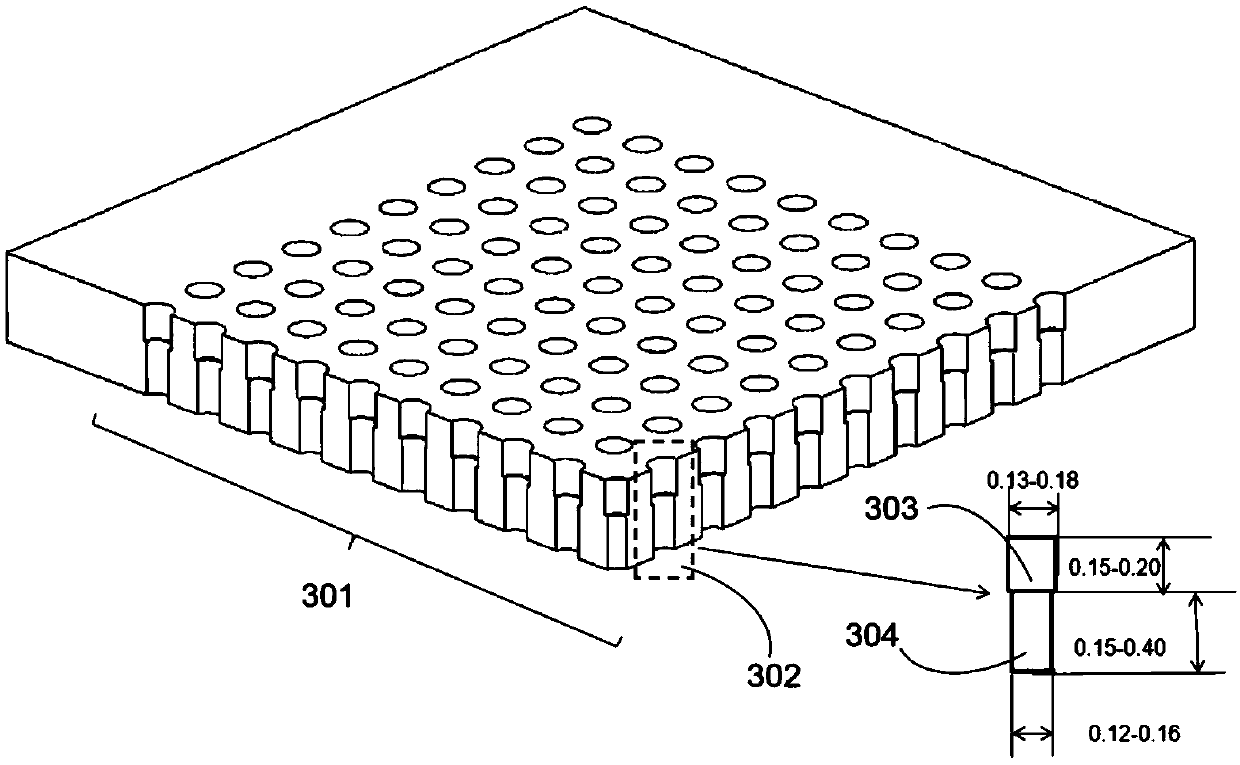

[0060] Please see attached image 3 , in this embodiment, the prepared synthetic carrier particle size screening chip 301 has an appearance size of 127 mm in length and 85 mm in width, which is the same as that of a common 96-well plate. The diameter of the upper opening 303 of the sieve structure 302 in the prepared synthetic carrier particle size screening chip 301 is 0.14 mm, the depth is 0.20 mm, the diameter of the lower end opening 304 is 0.13 mm, and the depth is 0.30 mm. is 0.3 mm.

[0061] Please see attached Figure 4 , in this embodiment, the prepared synthetic carrier particle size screening chip 301 is made of silicon material, which is prepared by dry etching twice. As shown in step 403, first, the photoresist 402 is spin-coated on the front surface of the silicon wafer 401, and the micropattern to be etched on the upper surface of the synthetic carrier particle size screening chip...

Embodiment 3

[0063] Embodiment 3 Synthetic carrier sorting method

[0064] The basic material of commercially available DNA synthesis carriers is porous glass, which is usually used to fill the synthesis columns used in commercial synthesizers. The particle size distribution range is wide, usually reaching about 0.12-0.18 mm. Compared with the synthetic carrier with larger particle size, the difference in the synthetic load of DNA can reach more than 3 times. For high-throughput oligonucleotide synthesis, the initial synthesis load varies too much, which can lead to significant differences in the yield of the target product. However, high-throughput oligonucleotide synthesis is usually used to construct high-throughput DNA libraries, perform long-sequence DNA or gene splicing, etc. If the yield of target products is too different, it will lead to poor DNA library uniformity and failure of long-sequence DNA splicing. Therefore, before applying the oligonucleotide synthesis reaction microch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com