Atomizing agent for cigarettes and method for increasing atomizing agent absorbing amount of conventional tobacco leaves

A technology of atomizing agent and tobacco leaves, which is applied in the fields of tobacco, application, and tobacco treatment, etc., which can solve the problems of poor absorption capacity of atomizing agent and inability to increase the adsorption or loading capacity of atomizing agent, so as to avoid complicated process and facilitate the absorption of fog The effect of reducing agent and reducing the proportion of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

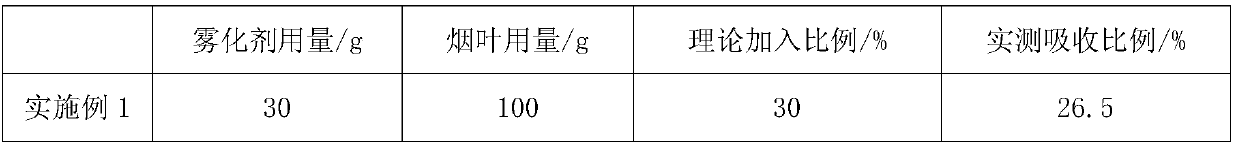

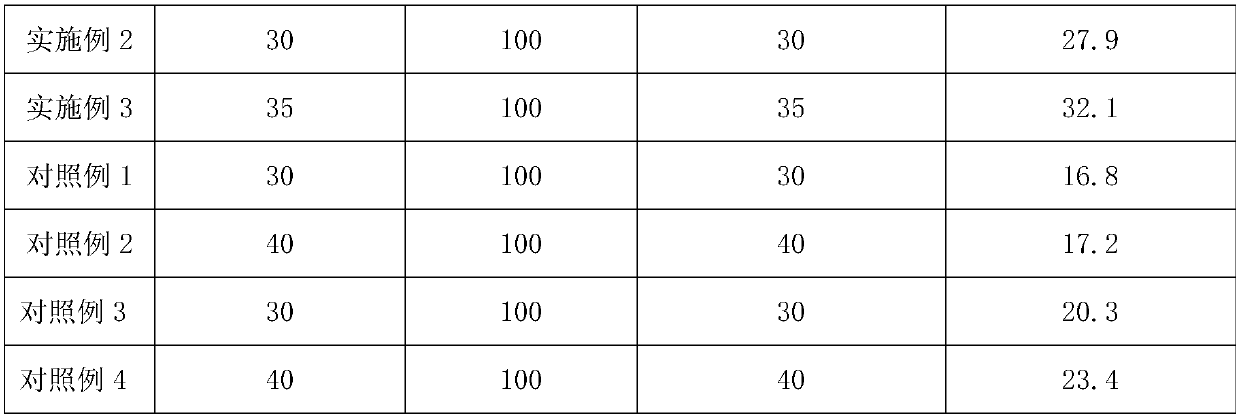

Embodiment 1

[0023] Embodiment 1 A kind of method for improving traditional tobacco leaf atomizing agent, its specific process is as follows:

[0024] (1) First prepare the atomizer according to the following formula: weigh sorbitol, glycerin, glycerol, triethylene glycol diacetate, methyl stearate according to the mass ratio of 1:10:10:7.5:3.5:0.7 Ester, dimethyl dodecanedioate, mixed uniformly to prepare cigarette atomizer A;

[0025] (2) 150g tobacco leaves are placed in steam explosion equipment, and steam explosion is carried out under the conditions of temperature 40°C, pressure 0.6MPa, and pressure retention time of 15 seconds; the steam explosion time is less than 0.01 second, and the pressure retention time is 10 to 60 seconds; The working medium of steam explosion is saturated water vapor;

[0026] (3) Put 30 g of the atomizer A for tobacco prepared in the step (1) into the feeding barrel, and after the steam explosion treatment in the step (2), quickly spray all the atomizer A ...

Embodiment 2

[0027] A kind of method that embodiment 2 provides to improve traditional tobacco leaf aerosol, its specific process is as follows:

[0028] (1) Weigh sorbitol, glycerin, glycerol, 7g triethylene glycol diacetate, methyl stearate, dodecanedioic acid diacetate according to the mass ratio 1:15:15:7:3:0.6 Methyl ester, mixed uniformly to prepare cigarette atomizer B;

[0029] (2) 100g tobacco leaves are placed in steam explosion equipment, and steam explosion is carried out under the conditions of temperature 45° C., pressure 0.6 MPa, and pressure retention time of 30 seconds. The steam explosion time is less than 0.01 second, and the pressure retention time is 10 to 60 seconds; The working medium of steam explosion is saturated water vapor;

[0030] (3) Put 30 g of the atomizer B for tobacco prepared in the step (1) into the feeding barrel, and after the steam explosion treatment in the step (2), quickly spray all the atomizer B for tobacco in the feeding barrel on the The sur...

Embodiment 3

[0031] A kind of method that embodiment 3 provides to improve traditional tobacco leaf aerosol, its specific process is as follows:

[0032] (1) Weigh sorbitol, glycerin, glycerol, triethylene glycol diacetate, methyl stearate, and dimethyl dodecanedioate according to the mass ratio of 1:20:20:7:3:0.5 ester, mixed uniformly to obtain atomizer C;

[0033] (2) Put 100g of tobacco leaves in the steam explosion equipment, and carry out steam explosion at a temperature of 45°C, a pressure of 0.8MPa, and a pressure retention time of 40 seconds. The steam explosion time is less than 0.01 seconds, and the pressure retention time is 10 to 60 seconds; steam explosion The working medium is saturated water vapor;

[0034] (3) Put 35g of the atomizer C for tobacco prepared in the step (1) into the feeding barrel, and after the steam explosion treatment in the step (2), quickly spray all the atomizer C for smoke in the feeding barrel on the The surface of the tobacco leaves after the blas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com