Loose moisture regain adaptive moisture control method and system based on digital physical model

A loose moisture regain, digital physics technology, applied in the application, processing, and preparation of tobacco. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

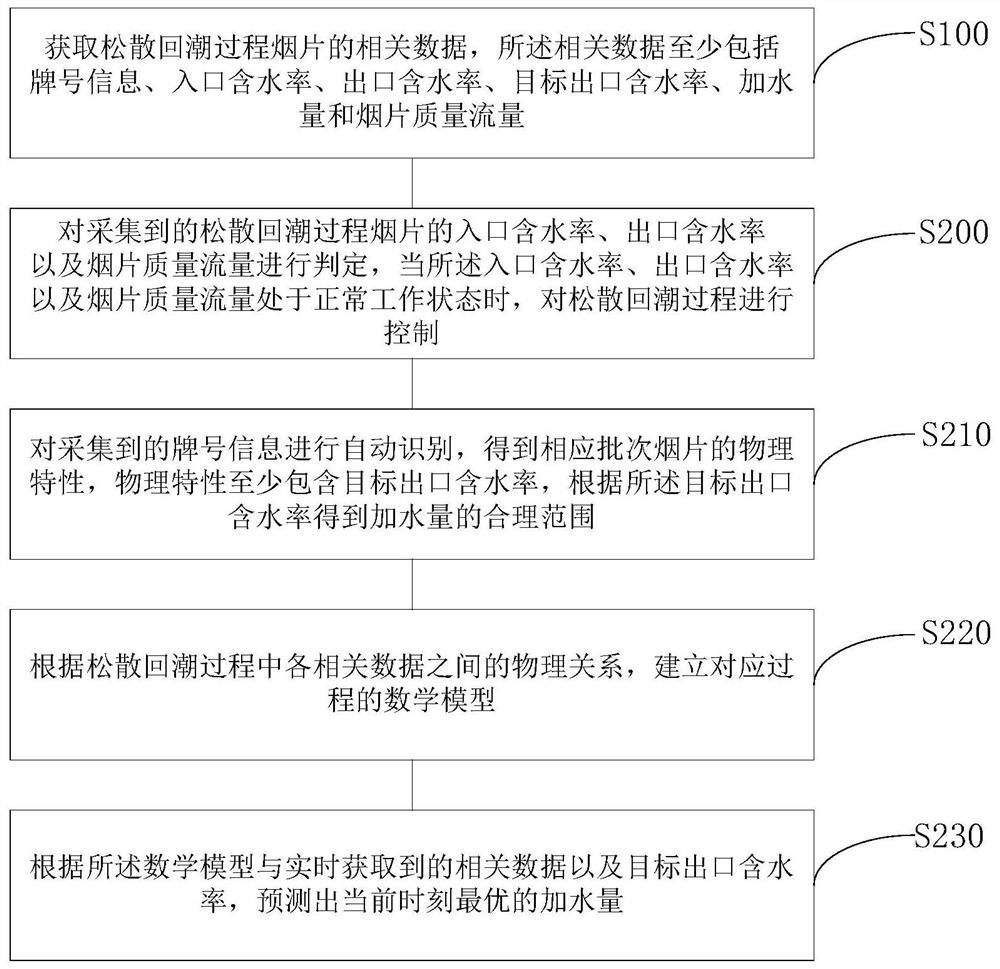

[0044] An adaptive moisture control method for loose moisture based on a digital physical model, such as figure 1 shown, including the following steps:

[0045] S100. Obtain relevant data of the loose tobacco sheet during the moisture regain process, the relevant data at least includes brand information, inlet moisture content, outlet moisture content, target outlet moisture content, water addition amount and mass flow rate of the tobacco sheet;

[0046]S200. Determine the inlet moisture content, outlet moisture content, and mass flow rate of the collected loose tobacco sheets during the moisture regaining process. Control the moisture regain process, wherein, the process of controlling the loose moisture regain process includes:

[0047] S210. Automatically identify the collected brand information to obtain the physical characteristics of the corresponding batch of cigarette sheets, the physical characteristics at least include the target outlet moisture content, and obtain ...

Embodiment 2

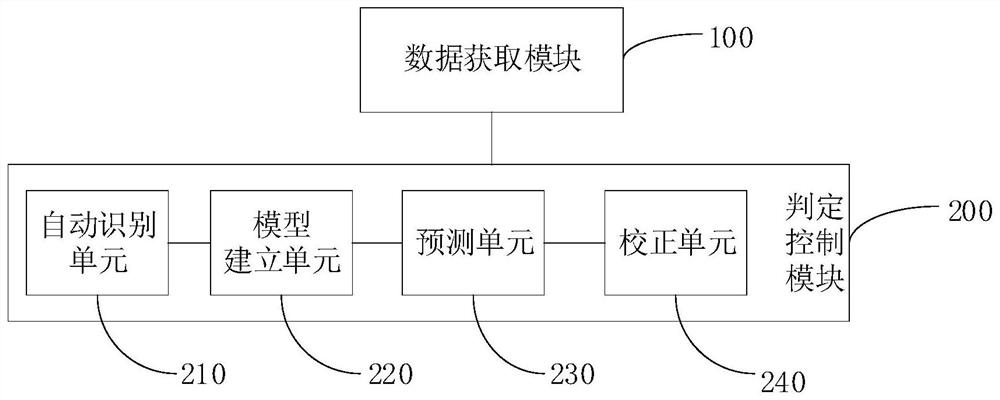

[0065] A loose moisture regain adaptive moisture control system based on a digital physical model, such as figure 2 As shown, it includes an acquisition data module 100 and a decision control module 200;

[0066] The data acquisition module 100 is used to acquire relevant data of the loose tobacco sheets during the moisture regaining process, the relevant data at least includes brand information, inlet moisture content, outlet moisture content, target outlet moisture content and mass flow rate of the tobacco sheets;

[0067] The determination control module 200 is used to determine the inlet moisture content, outlet moisture content and mass flow rate of the collected loose tobacco sheets in the moisture regaining process. During the normal working state, the loose regaining process is controlled, wherein the judgment control module 200 includes an automatic identification unit 210, a model building unit 220 and a prediction unit 230:

[0068] The automatic identification un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com