Selenium-enriched bacillus bifidus micro-capsules

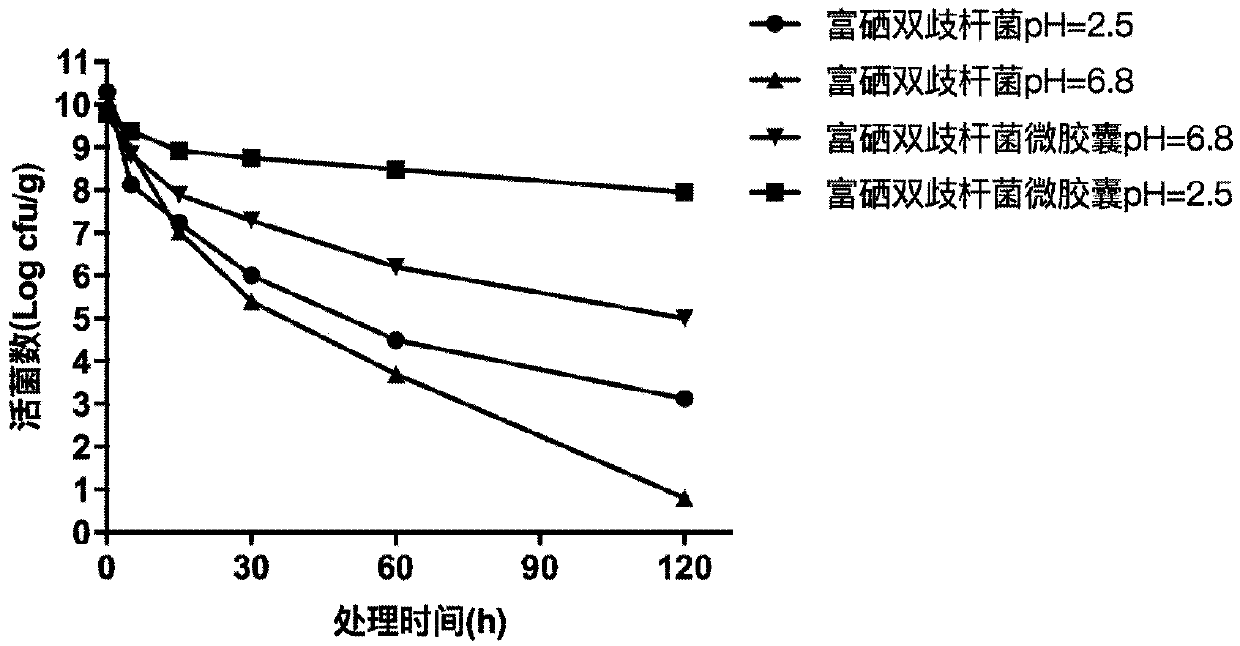

A bifidobacteria and microcapsule technology, applied in the field of microbial preparations, can solve the problems that microcapsules are not resistant to gastric acid and bile salts, the device efficiency is not easy to scale up production, etc. rate, and the effect of prolonging the storage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

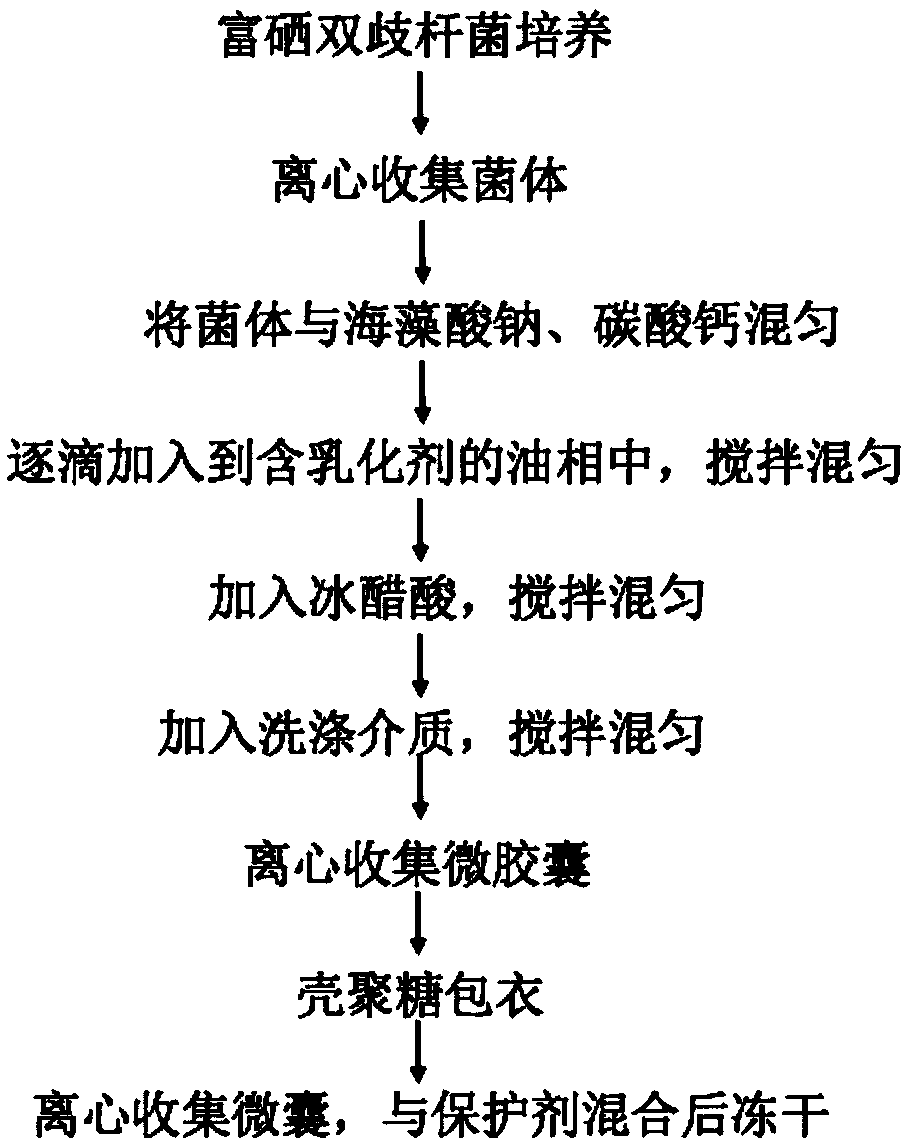

Method used

Image

Examples

Embodiment 1

[0031] The preparation of embodiment 1 selenium-enriched bifidobacteria

[0032] The 16S rDNA nucleotide sequence of Bifidobacterium longum DD98 (Latin name Bifidobacterium longum) used in the present invention is shown in SEQ ID No: 1. The bifidobacterium is preserved in the China General Microorganism Culture Collection Management Center (No. 3, No. 1, Beichen West Road, Chaoyang District, Beijing, Institute of Microbiology, Chinese Academy of Sciences, Zip Code 100101), and the preservation number is CGMCC No. 16573.

[0033] The main components of the RCM medium are beef extract, peptone, yeast powder, glucose, starch, sodium chloride, sodium acetate, L-cysteine hydrochloride, and the content of each component can be adjusted according to the conventional knowledge in the art.

[0034] Preferably, every 10 parts of RCM medium is composed of: 0.1 part of beef extract, 0.05 part of peptone, 0.03 part of yeast powder, 0.05 part of glucose, 0.01 part of starch, 0.05 part of ...

Embodiment 2

[0038] Example 2 Preparation of selenium-enriched bifidobacterium microcapsules

[0039] Mix sodium alginate solution, selenium-enriched bifidobacterium sludge and calcium carbonate powder evenly, then add the above mixed solution drop by drop into soybean oil containing emulsifier, stir, and then add Soybean oil with glacial acetic acid, stir, add emulsifier solution therein, stand still after stirring, until the microcapsules sink to the bottom of the water phase, absorb the oil phase, and centrifuge the water phase (3800r / min, centrifugal 2min) to obtain microcapsules , and then use the washing medium (1% emulsifier solution) to wash the microcapsules twice, remove the residual oil phase, and finally wash twice with sterile saline to obtain uncoated selenium-enriched bifidobacterium microcapsules.

[0040] According to Table 1, each process parameter is screened

[0041]

[0042]

[0043] The above research results show that:

[0044] 1. When Tween 80 is used as an ...

Embodiment 3

[0055] Embodiment 3 microcapsule coating

[0056] The prepared uncoated bifidobacterium selenium-enriched microcapsules were resuspended in a certain volume of purified water, then resuspended in 0.2% coating material solution and stirred, and after the coating was completed, the microcapsules were collected by centrifugation, and used The bacteria were washed twice with normal saline to obtain the coated selenium-enriched bifidobacteria microcapsules. Refer to Table 2 to investigate the effects of different conditions on the embedding rate and particle size during the coating process.

[0057] Table 2 is the effect of different conditions on the embedding rate and particle size in the microcapsule coating process

[0058]

[0059]

[0060] in conclusion:

[0061] 1. Although the particle size of the microcapsules is increased after coating with chitosan, the embedding rate is significantly higher than that of whey protein and polylysine, so chitosan is selected as the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com