Special compound feed for juvenile Basa fish and preparation method thereof

A compound feed, pangasius technology, applied in the field of aquaculture, can solve problems such as the influence of organ development and metabolism, the unsound development of juvenile fish organs, and the influence on the survival rate of juvenile fish, achieving high protein content, improving immunity and digestion ability, The effect of improving feed utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

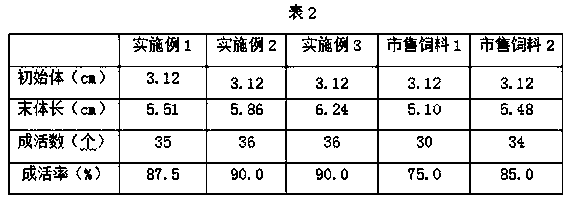

Examples

Embodiment 1

[0035] (1) 20 parts of domestic semi-skimmed fish meal, 16 parts of high-gluten flour, 1 part of corn, 11 parts of soybean meal, 10 parts of rapeseed meal, 0.75 parts of minerals, 0.2 parts of choline chloride, 1.35 parts of calcium dihydrogen phosphate, After mixing 3 parts of shrimp shell powder and 6.5 parts of pork powder, pulverize through an ultrafine pulverizer, and sieve through an 80-mesh sieve to obtain mixture A;

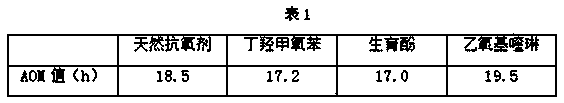

[0036] (2) Add 1 part of soybean oil, 0.2 part of multidimensional, 0.1 part of VC ester, 5 parts of natural antioxidant and 1 part of natural antifungal agent to the mixture A for secondary mixing, and put it in the room with ultraviolet disinfection lamp Stir and mix in the container for 4h to obtain mixture B;

[0037] The natural antioxidant in this example is to first mix 2 parts of tea leaves and 3 parts of Eucommia leaves, and carry out aroma enhancement and drying through an aroma enhancing machine. The aroma enhancing temperature is 50°C, and the...

Embodiment 2

[0042] (1) 24 parts of domestic semi-skimmed fish meal, 18 parts of high-gluten flour, 3 parts of corn, 15 parts of soybean meal, 15 parts of rapeseed meal, 2 parts of sunflower seed meal, 1.5 parts of minerals, 0.3 parts of choline chloride, phosphoric acid 1.75 parts of calcium dihydrogen, 5 parts of shrimp shell powder and 12 parts of pork powder are mixed and pulverized by an ultrafine pulverizer, and the mixture A is obtained after sieving through an 80-mesh sieve;

[0043](2) Add 3 parts of soybean oil, 0.2 parts of multidimensional, 0.1 part of VC ester, 7 parts of natural antioxidant and 2 parts of natural antifungal agent to the mixture A for secondary mixing, and put it in the room with ultraviolet disinfection lamp Stir and mix in the container for 5 hours to obtain mixture B;

[0044] The natural antioxidant is first mixed with 3 parts of tea leaves and 4 parts of eucommia leaves, and then dried by an aroma enhancing machine at a temperature of 55°C for 2.5 hours. ...

Embodiment 3

[0049] (1) 28 parts of domestic semi-skimmed fish meal, 21 parts of high-gluten flour, 5 parts of corn, 18 parts of soybean meal, 20 parts of rapeseed meal, 3 parts of sunflower meal, 2 parts of minerals, 0.5 parts of choline chloride, phosphoric acid 2.25 parts of calcium dihydrogen, 7 parts of shrimp shell powder and 19 parts of pork powder are mixed and pulverized by an ultrafine pulverizer, and the mixture A is obtained after sieving through an 80-mesh sieve;

[0050] (2) Add 4 parts of soybean oil, 0.2 parts of multidimensional, 0.1 part of VC ester, 9 parts of natural antioxidant and 3 parts of natural antifungal agent to the mixture A for secondary mixing, and put it in the room with ultraviolet disinfection lamp Stir and mix in the container for 6h to obtain mixture B;

[0051] The natural antioxidant is first mixed with 4 parts of tea leaves and 5 parts of eucommia leaves, and dried through an aroma enhancing machine. The temperature of aroma enhancement is 60°C, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com