U-shaped steel composite beam member with self-contained shearing parts

A technology of shear parts and composite beams, which is applied in the direction of building components, building structures, floor slabs, etc., can solve the problems of large welding workload of shear connectors, less welding workload of shear parts, waste of steel on the upper flange, etc. , to achieve the effect of improving stability and fire prevention ability, reducing labor cost and good construction stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

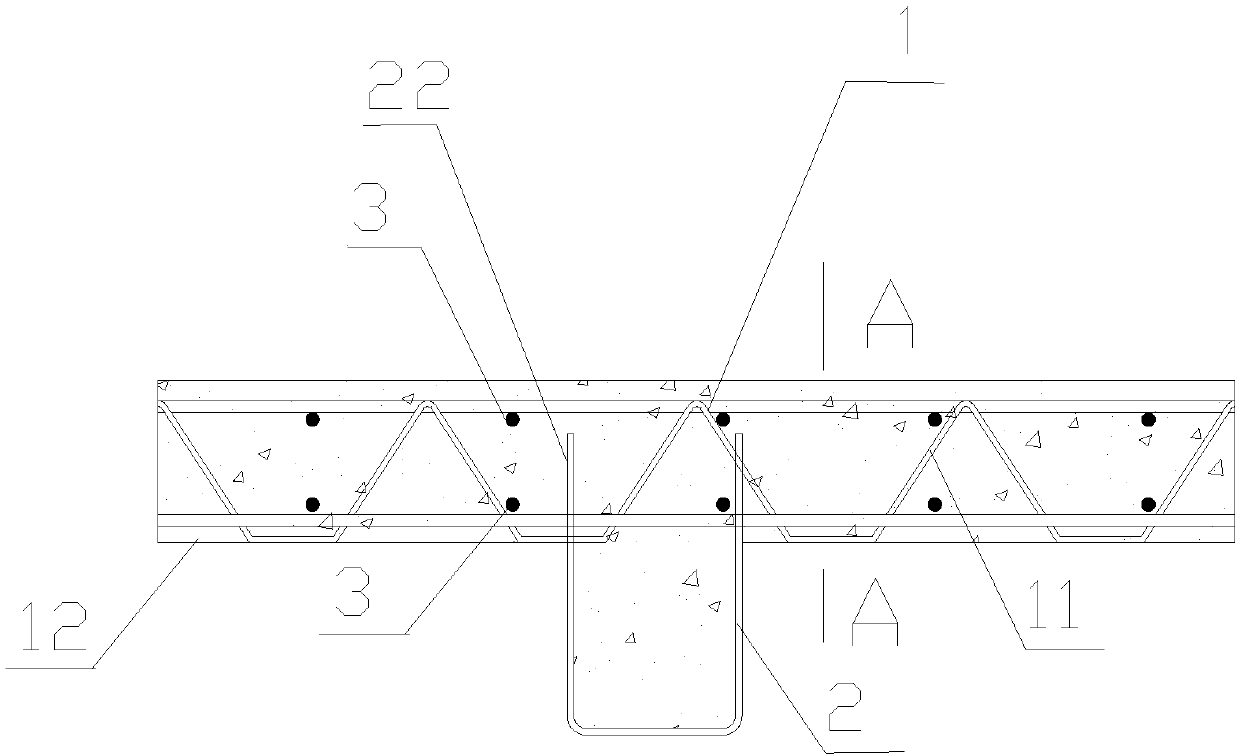

Embodiment 1

[0035] Example 1 as figure 1 Shown: a U-shaped steel composite beam member with its own shear parts according to the present invention, including a reinforced truss floor deck 1, a steel beam 2, distributed steel bars 3, and a concrete layer 4, and the reinforced truss floor deck 1 It includes several steel bar trusses 11 and bottom film 12, the steel bar trusses 11 are arranged in parallel, and are fixed by a plurality of distributed steel bars 3 perpendicular to the steel bar trusses 11; the bottom film 12 is laid horizontally on the bottom of the steel bar trusses 11; The steel beam 2 is a U-shaped steel beam arranged horizontally, and the two edges of the steel beam 2 along the axial direction are provided with grooves 21 for clamping the steel truss, so that the edges of the steel beam are toothed edges 22, and adjacent The part between the two grooves is used as the shearing part of the steel beam; the steel beam truss 11 or the distributed steel bar 12 are inserted into...

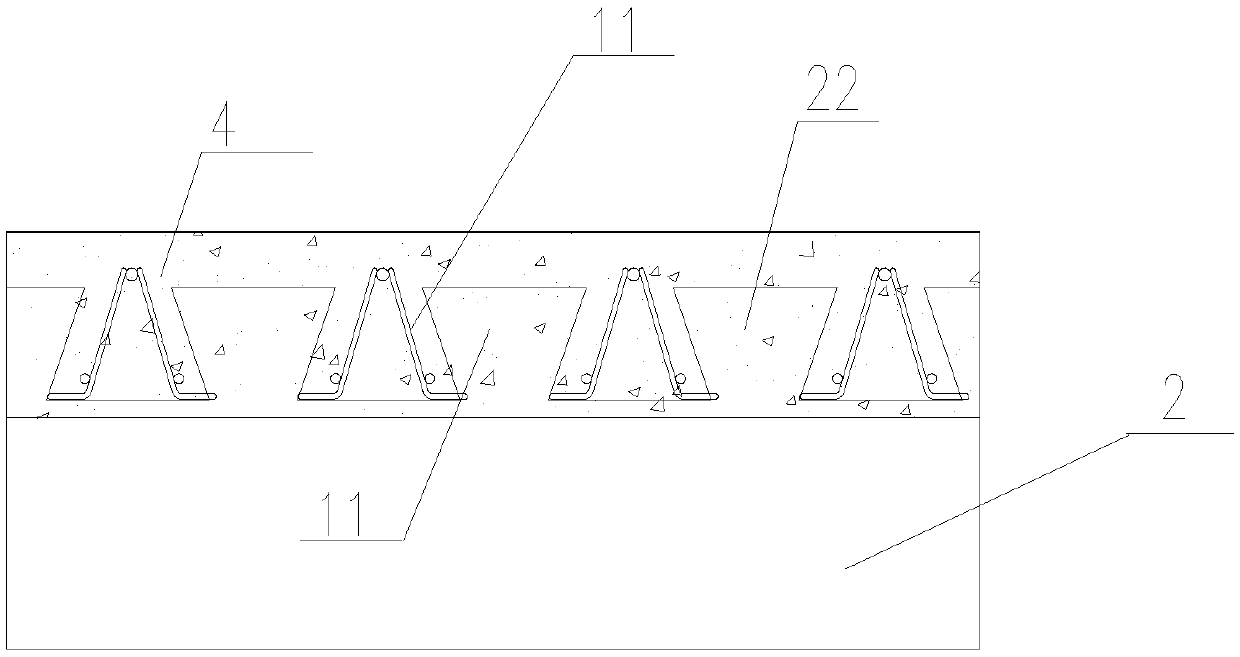

Embodiment 2

[0046] Example 2 as figure 2 As shown, the difference between this embodiment and Embodiment 1 is that: the steel beams and steel trusses are parallel to the bottom membrane, and the steel beams and steel trusses are parallel; other structures are the same as in Embodiment 1.

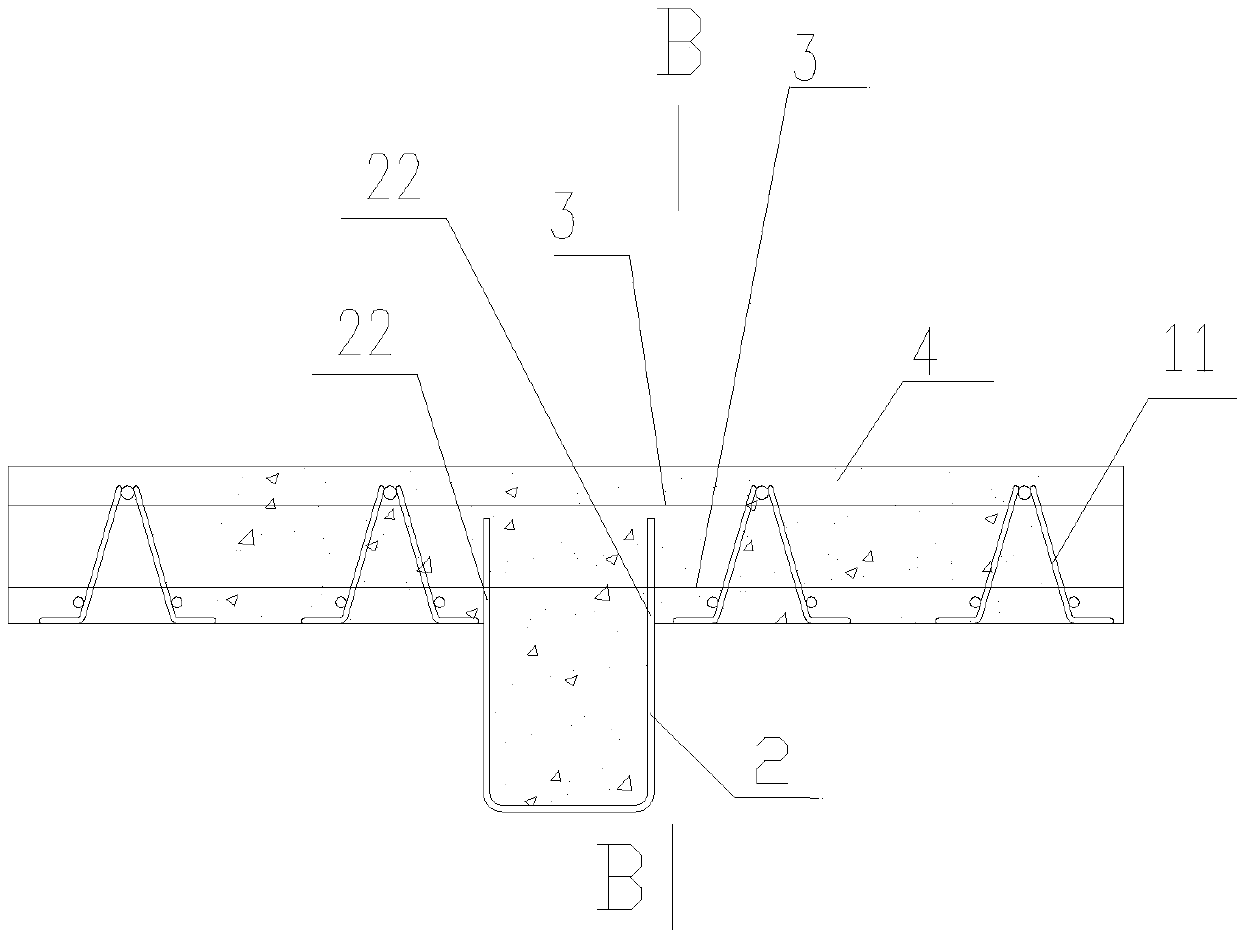

Embodiment 3

[0047] Embodiment 3 The difference between this embodiment and Embodiment 1 is that the steel girder 2 is a welded U-shaped steel girder, the steel girder 2 includes a bottom plate and two side plates, and the two opposite edges of the bottom plate along the axial direction are respectively The side plate is welded, and the three form a U-shaped steel beam, and the top edge of the side plate is provided with a trapezoidal groove.

[0048] Both the steel beam and the steel truss are parallel to the bottom membrane, and the steel beam is perpendicular to the steel truss.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com