Method for recovering metal from laterite-nickel ore leaching liquid and producing magnesium salt by using resin adsorption method

A technology of laterite nickel ore and resin adsorption, applied in the direction of improving process efficiency, can solve the problems of low recovery rate of valuable metals, increased production cost, sulfide pollution, etc., and achieves low regeneration cost, long service life, and high purity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

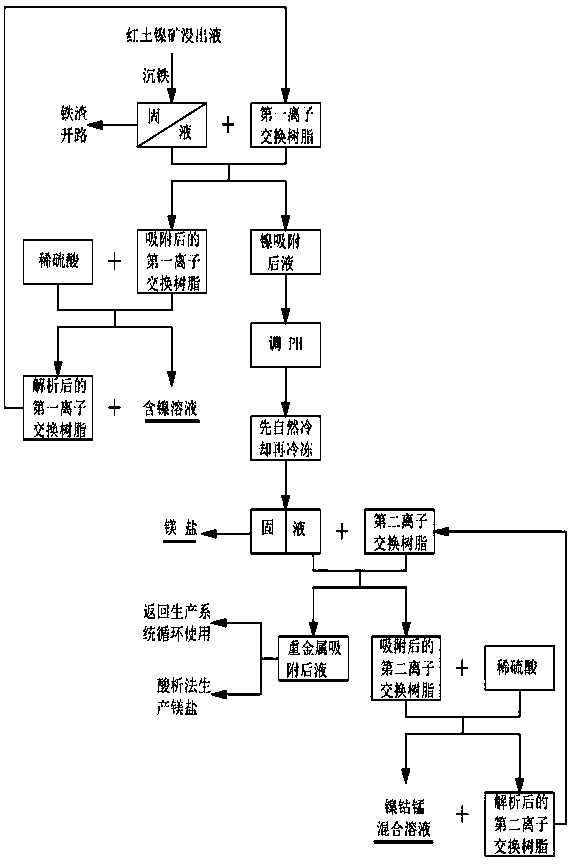

[0024] see figure 1 , the resin adsorption method of the present invention recovers metals in laterite nickel ore leaching solution and produces magnesium salts, comprising the following steps: (1) The laterite nickel ore leaching solution undergoes iron precipitation and solid-liquid separation to obtain iron slag and iron-deposited solution. (2) The iron-precipitated liquid passes through the first ion exchange resin to selectively adsorb nickel to obtain the nickel-adsorbed liquid and the first ion-exchange resin after adsorption; the pH of the iron-precipitated liquid is 2-5; the components of the iron-precipitated liquid And its concentration is: nickel 2g / L-10g / L, cobalt<0.5g / L, manganese<0.5g / L, iron<0.01g / L, magnesium 50g / L-80g / L. The first ion-exchange resin is the corresponding hydrogen-type resin after the LSC-930 resin is converted to hydrogen-type, and the first ion-exchange resin preferentially adsorbs nickel. (3) Analyze the first ion exchange resin after adsor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com