Daptomycin fermentation culture medium and preparation method thereof

A fermentation medium and technology of daptomycin, applied in the field of daptomycin fermentation medium and its preparation, can solve the problems of high raw material cost and low yield of Streptomyces roseospora, and achieve low price, convenient transportation and storage , the effect of chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] The impact of embodiment 1 maltodextrin dosage on daptomycin output

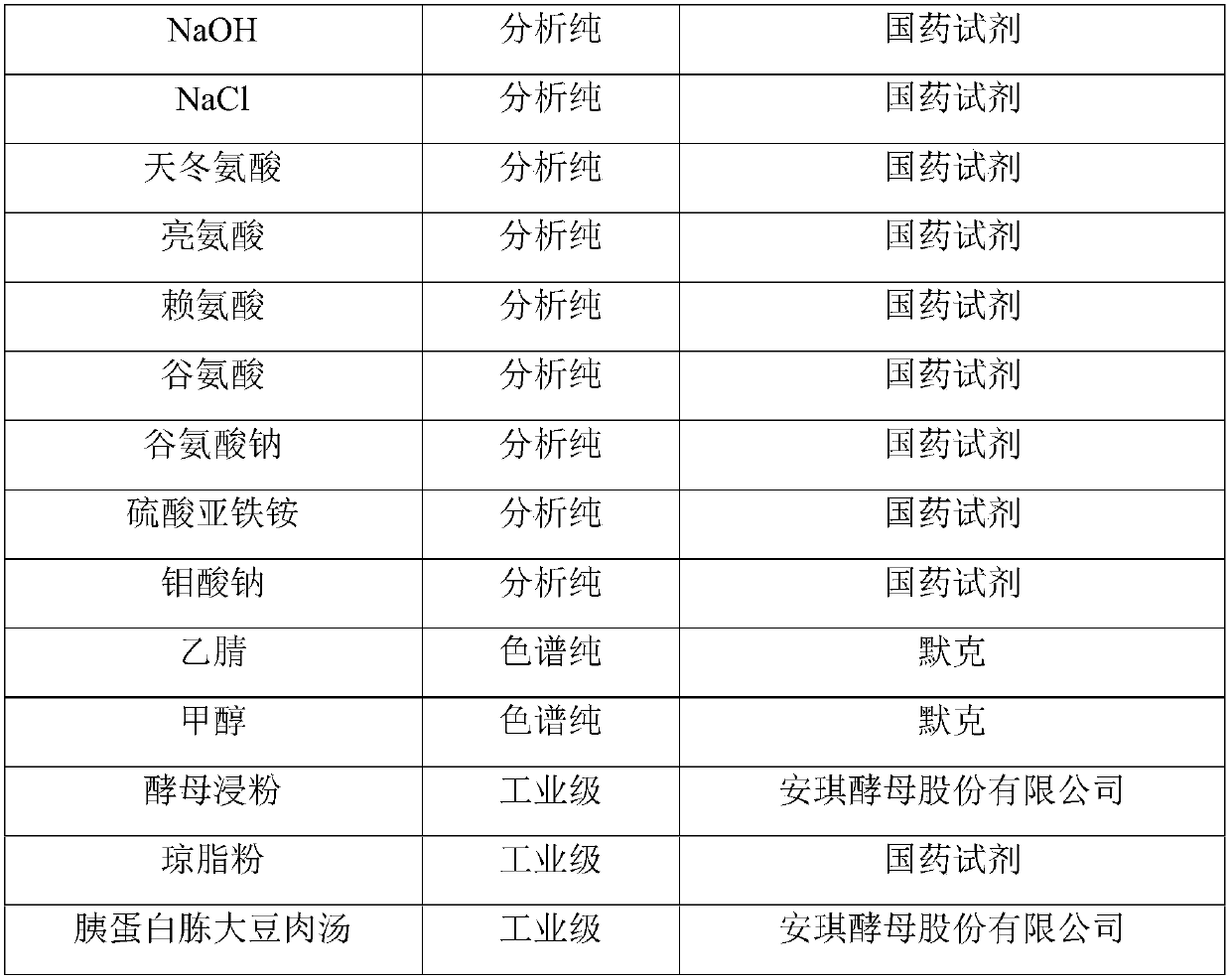

[0056] The carbon sources in the fermentation medium are maltodextrin and glucose, the dosages are 7.2g / 100mL and 1.8g / 100mL respectively, and the remaining components are durian yeast powder 1.65g / 100mL, ferrous ammonium sulfate 0.086g / 100mL, Adjust to 7.5. The medium components are shown in the table below:

[0057]

[0058] According to the formulas of the above-mentioned fermentation media, the shake flasks were fermented for 5 days, and the fermentation units were measured by high performance liquid phase. According to the above experimental results, when the dosages of maltodextrin and glucose are 7.2g / 100mL and 1.8g / 100mL respectively, the daptomycin fermentation unit can maintain the same level as the existing fermentation unit and can reduce the production cost.

Embodiment 2

[0064] The impact of embodiment 2 carbon source type on daptomycin output

[0065] The carbon source in the fermentation medium is 7.2g / 100mL maltodextrin, the remaining components are Durian yeast powder 1.65g / 100mL, ferrous ammonium sulfate 0.086g / 100mL, and the pH is adjusted to 7.5. Add 1.8g / 100mL of another carbon source on the basis of maltodextrin, and the components of each medium are shown in the table below:

[0066]

[0067]

[0068] According to the formulas of the above-mentioned fermentation media, the shake flasks were fermented for 5 days, and the fermentation units were measured by high performance liquid phase. According to the above experimental results, on the basis of maltodextrin, molasses or brown sugar can also be added as a carbon source to reduce costs and further increase production. When molasses is added, the fermentation unit of daptomycin is the highest.

[0069] The impact of comparative example 2 sucrose on daptomycin yield

[0070] The...

Embodiment 3

[0073] The influence of embodiment 3 carbon source ratio on daptomycin output

[0074] The amount of carbon source in the fermentation medium is 9g / 100mL, the carbon source types are maltodextrin and molasses, the remaining components are durian yeast powder 1.65g / 100mL, ferrous ammonium sulfate 0.086g / 100mL, and the pH is adjusted to 7.5. Change the ratio of maltodextrin and molasses, and the components of each medium are shown in the table below:

[0075]

[0076] According to the formulas of the above-mentioned fermentation media, the shake flasks were fermented for 5 days, and the fermentation units were measured by high performance liquid phase. According to the above experimental results, on the basis of cost control, when the amount of maltodextrin is 7.5g / 100mL and the amount of molasses is 1.5g / 100mL, the fermentation unit of daptomycin is the highest.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com