High-mechanical strength and biodegradable PLA-PHBV composite material, preparation method thereof and thin film

A technology of mechanical strength and biodegradation, which is applied in the field of PLA/PHBV composite materials and its preparation, can solve problems such as low crystallinity, lower melting temperature, and need to increase glass transition temperature, so as to improve crystallinity, reduce spherulite size, Effect of modulus and glass transition temperature increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

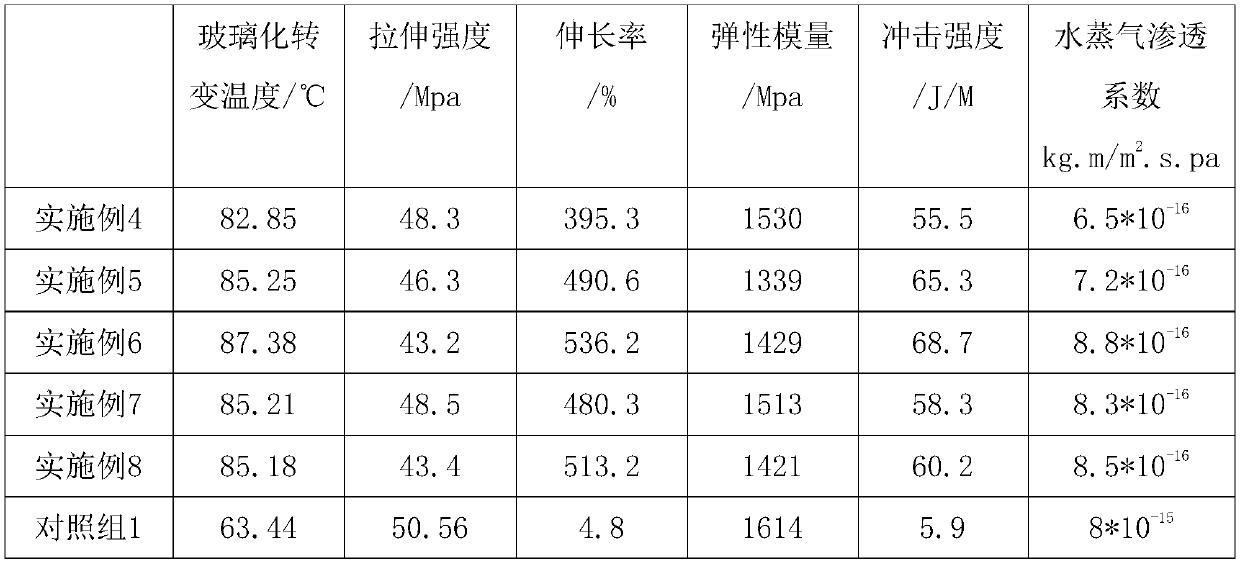

Examples

Embodiment 1

[0035] Preparation of ethylene-vinyl acetate copolymer grafted glycidyl methacrylate modified toughening agent:

[0036] Ethylene-vinyl acetate copolymer (vinyl acetate content is less than 40%) 40 parts by weight;

[0037] 10 parts by weight of glycidyl methacrylate;

[0038] Initiator dibenzoyl peroxide BPO 1 weight part;

[0039] Preparation of EVA-g-GMA:

[0040] Weigh EVA, GMA, BPO and add them to the rotational rheometer in turn, and banbury at 110-140°C and 90-130rad / min for 5-20min to prepare EVA-g-GMA. The grafted sample was dissolved in chloroform, and then precipitated with ethanol for several times and suction-filtered, and the operation was repeated three times, and then the purified product was dried in a vacuum oven at 50° C. for 24 hours.

Embodiment 2

[0042] Preparation of EVA-g-GMA:

[0043] Ethylene-vinyl acetate copolymer (vinyl acetate content is less than 40%) 50 parts by weight;

[0044] 3 parts by weight of glycidyl methacrylate;

[0045] Initiator dibenzoyl peroxide BPO 0.5 parts by weight;

Embodiment 3

[0047] Preparation of EVA-g-GMA:

[0048] Ethylene-vinyl acetate copolymer (vinyl acetate content is less than 40%) 60 parts by weight;

[0049] 5 parts by weight of glycidyl methacrylate;

[0050] Initiator dibenzoyl peroxide BPO 2 parts by weight;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com