Antistatic agent with flame retarding performance, as well as preparation method and application thereof

A technology of antistatic agent and flame retardant performance, applied in the field of antistatic agent and its preparation, can solve the problems of skin harmfulness, poor heat resistance, poor resin compatibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

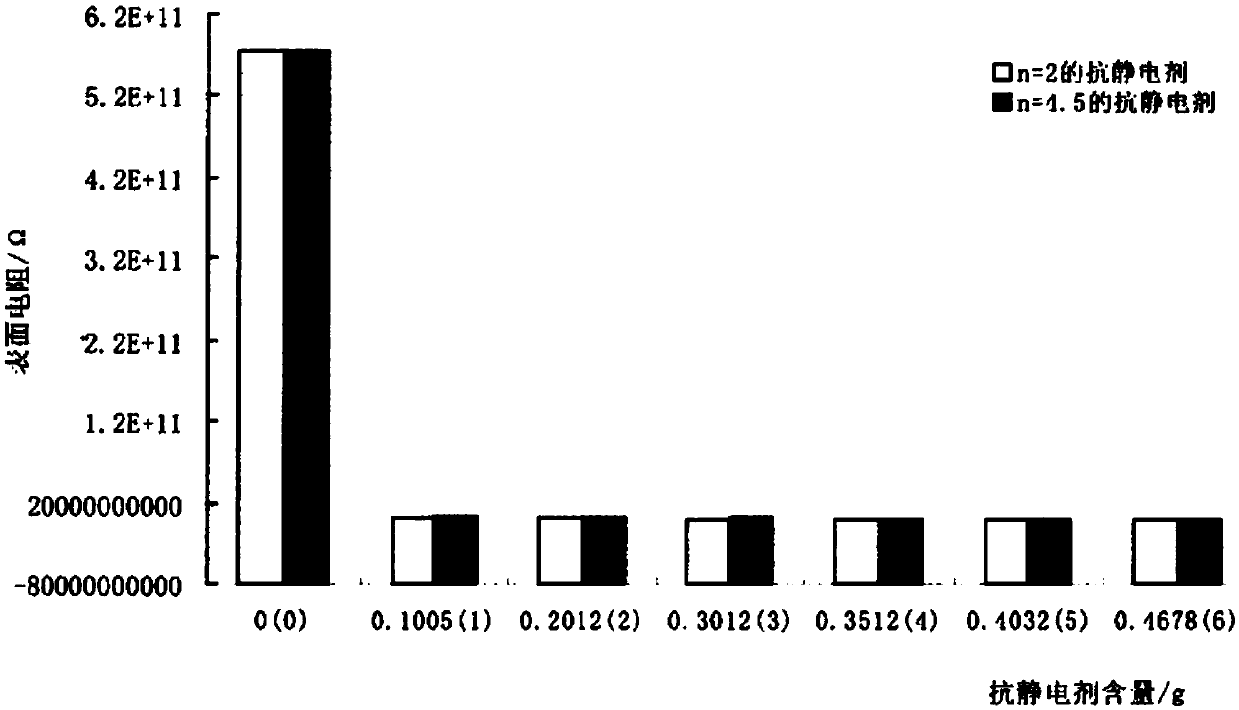

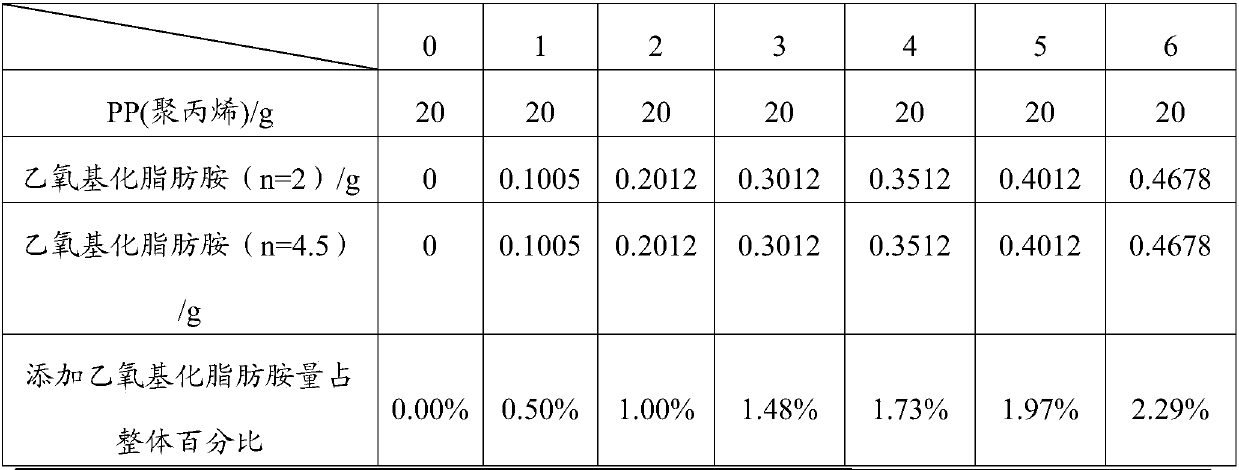

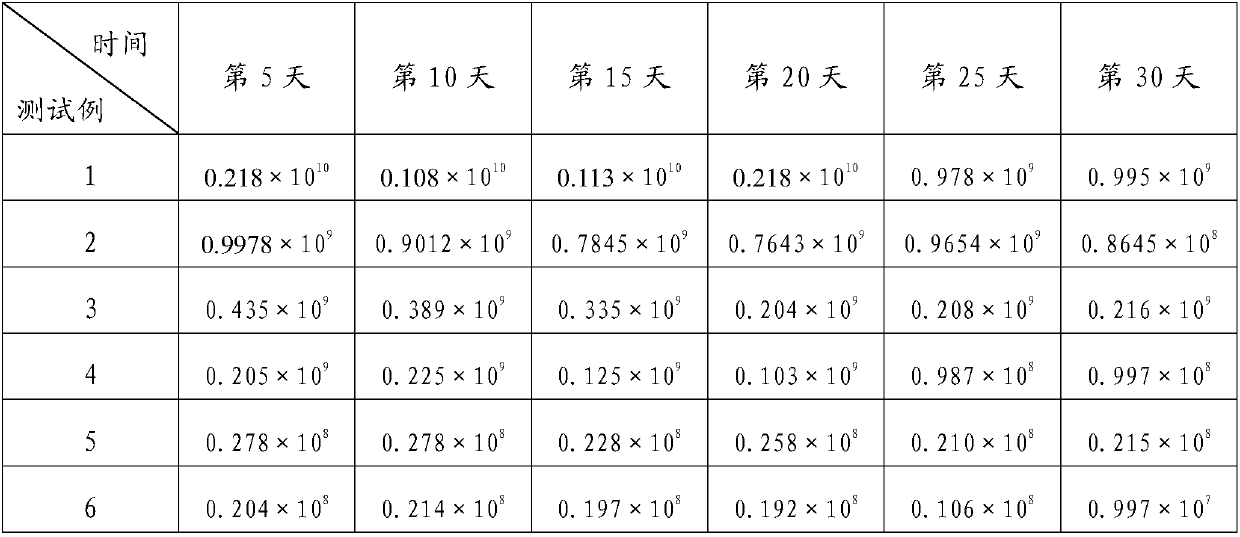

Examples

preparation example Construction

[0031] In one embodiment, a kind of preparation method of antistatic agent with flame retardant property, comprises the steps:

[0032] Under normal pressure, fatty amine and ethylene oxide are used as raw materials and hydrochloric acid is used as catalyst to synthesize ethoxylated fatty amine; the reaction formula is as follows:

[0033] RNH 2 +2C 2 h 4 O→RN(CH 2 CH 2Oh) 2 ;

[0034] RN(CH 2 CH 2 Oh) 2 +(m+n-2)C 2 h 4 O→RN(CH 2 CH 2 O) m H(CH 2 CH 2 O) n H; among them, CH 2 CH 2 The addition number n=2 of the O group, m is the polymerization addition number, which is naturally generated;

[0035] The antistatic agent with flame retardant properties is obtained by borate reaction of ethoxylated fatty amine and boric acid, and the reaction formula is as follows:

[0036] 2RN (CH 2 CH 2 O) m H(CH 2 CH 2 O) n H+B(OH) 3 →RN(CH 2 CH 2 O) m (CH 2 CH 2 O) n BRN (CH 2 CH 2 O) m (CH 2 CH 2 O) n H+3H 2 O.

[0037] In order to further illustrate ...

Embodiment

[0086] 1. Under normal pressure, use dodecylamine and ethylene oxide as raw materials and hydrochloric acid as a catalyst to synthesize ethoxylated dodecyl / octadecylamine. Specific steps: (1) Add 185g of dodecylamine and excess hydrochloric acid (catalyst) into a three-necked flask, turn on the magnetic heating stirrer to heat, and at the same time, pass in nitrogen to purge the device for about 30 minutes, and when the temperature rises to 100 At ℃, turn off the nitrogen gas, then slowly introduce ethylene oxide gas, and adjust the flow rate so that the flow rate is 14ml / min. When the temperature rises to about 120°C, keep the temperature basically unchanged. After the reaction lasts for 6 hours, stop feeding ethylene oxide gas, let the reaction continue for 30 minutes, and then the reaction system cools down naturally; (2) When the temperature drops to about 80°C , Nitrogen gas was passed into and purged for 20 minutes to remove the remaining ethylene oxide gas in the reacto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com