A method for the controllable preparation of manganese oxides with different structures using manganese terephthalate dihydrate as a precursor

A technology of terephthalic acid and manganese phthalate, applied in the direction of manganese oxide/manganese hydroxide, etc., can solve the problems of single product type, destruction of complex skeleton, single reaction conditions, etc., to achieve the effect of regulating performance and improving species

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

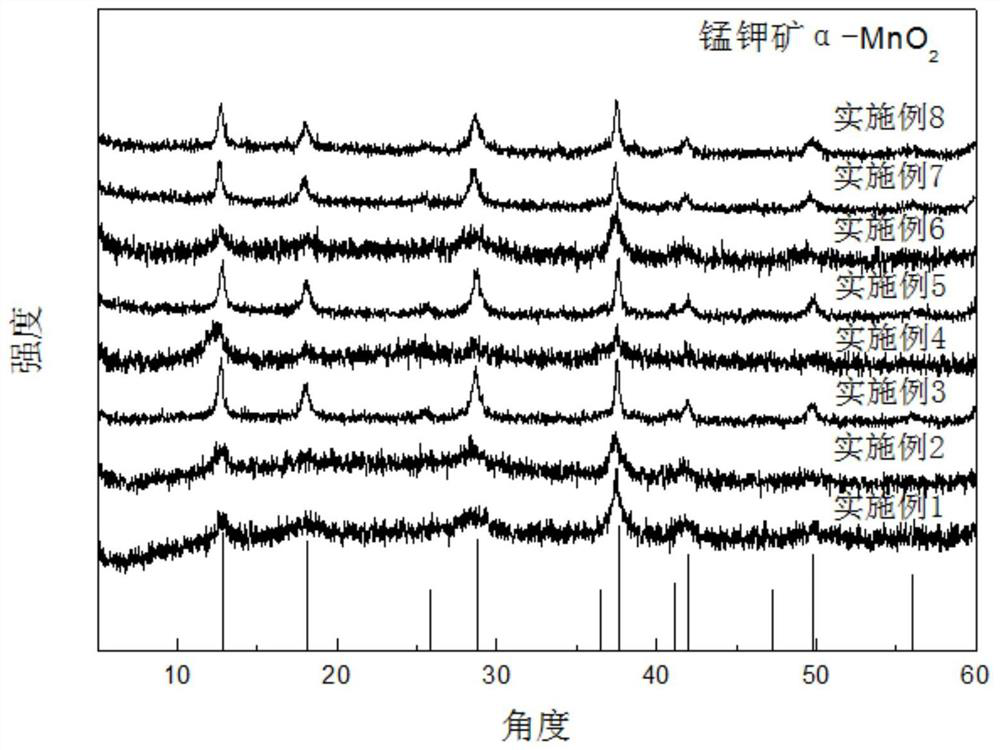

[0024] Add 0.025g (0.157mmol) of potassium permanganate and 0.080g (0.314mmol) of manganese terephthalate dihydrate into a glass bottle with a Teflon lid, and then add 10mL of H 2 SO 4 Aqueous solution, stirred and mixed evenly, left to react for 3.5 days at 85°C under airtight conditions, cooled naturally to room temperature, poured out the supernatant, washed the solid product at the bottom with 0.1mol / L NaOH aqueous solution, centrifuged, and cooled at 60°C Dry to constant weight to get 2×2 tunnel-type manganite α-MnO 2 . Depend on figure 1 It can be seen that the powder X-ray diffraction curve of the product obtained is consistent with the standard PDF card, indicating that the product is manganese ore.

Embodiment 2

[0026] Add 0.025g (0.157mmol) of potassium permanganate, 0.080g (0.314mmol) of manganese terephthalate dihydrate, and 10mL of deionized water into a glass bottle with a polytetrafluoroethylene cover, stir and mix evenly. Stand at 85°C for 3.5 days, cool to normal temperature naturally, pour out the supernatant, wash the solid product at the bottom with 0.1mol / L NaOH aqueous solution, centrifuge, and dry to constant weight at 60°C to obtain 2×2 Tunnel type manganese potash ore α-MnO 2 (See figure 1 ).

Embodiment 3

[0028] Add 0.050g (0.314mmol) of potassium permanganate and 0.080g (0.314mmol) of manganese terephthalate dihydrate into a glass bottle with a Teflon cover, then add 10mL of NaOH aqueous solution with pH=9, stir and mix well , standing at 85°C for 3.5 days under airtight conditions, naturally cooling to room temperature, pouring out the supernatant, washing the solid product at the bottom with 0.1mol / L NaOH aqueous solution, centrifuging, and drying at 60°C to constant weight, Get 2×2 tunnel type manganese α-MnO 2 (See figure 1 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com