Method and device for manufacturing metal lining of 3D printing composite material space pressure vessel

A technology of 3D printing and pressure vessels, which is applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of inability to guarantee the accuracy and organizational performance of molded products, complex manufacturing processes, etc., to ensure dimensional accuracy and material mechanical properties, reduce The effect of production cost and avoiding the influence of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

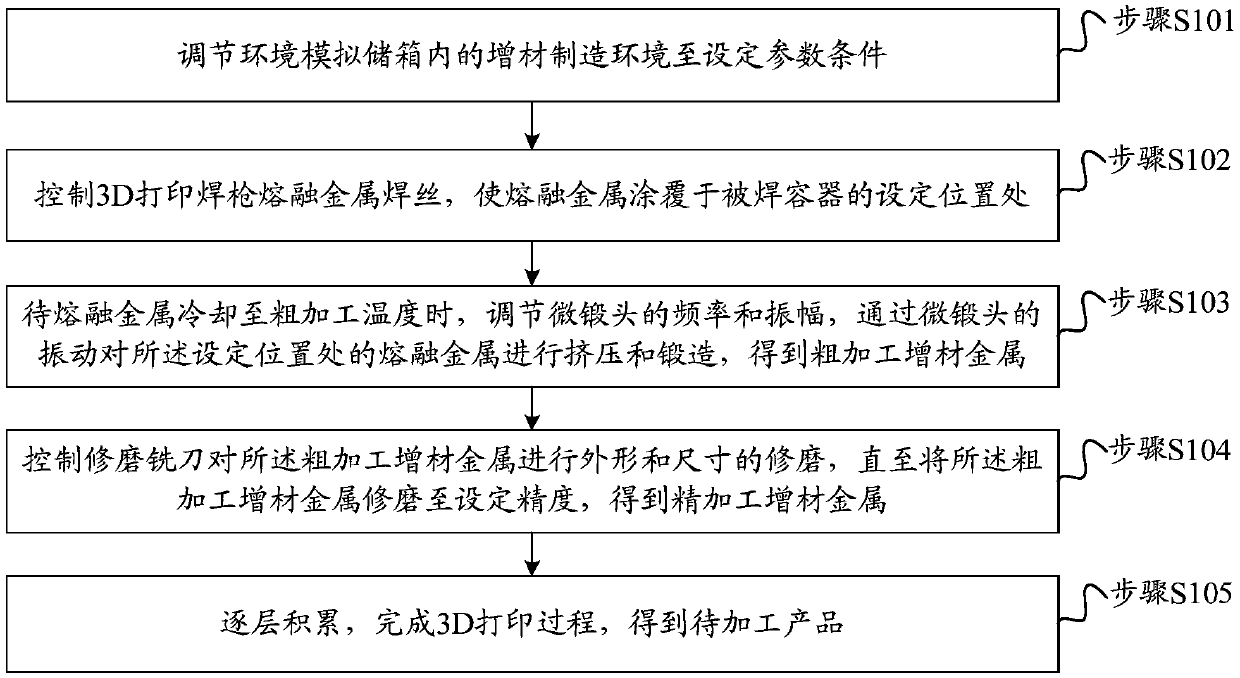

[0035] Such as figure 1 , is a flow chart of the steps of a method for manufacturing a metal lining of a 3D printed composite material space pressure vessel described in an embodiment of the present invention. The method for manufacturing a metal inner lining of a 3D printed composite material space pressure vessel includes:

[0036] Step S101, adjusting the additive manufacturing environment in the environment simulation tank to the set parameter conditions.

[0037] In this embodiment, the set parameter conditions include but not limited to: set temperature conditions, set pressure conditions and set gas filling conditions.

[0038] Preferably, the set temperature conditions can be determined according to the forging temperature range amplitude of the molten metal, the time required for forging and the cooling rate of the material, so as to ensure that the beginning and end of forging are the upper and lower limits of the forging temperature.

[0039] Preferably, the set pr...

Embodiment 2

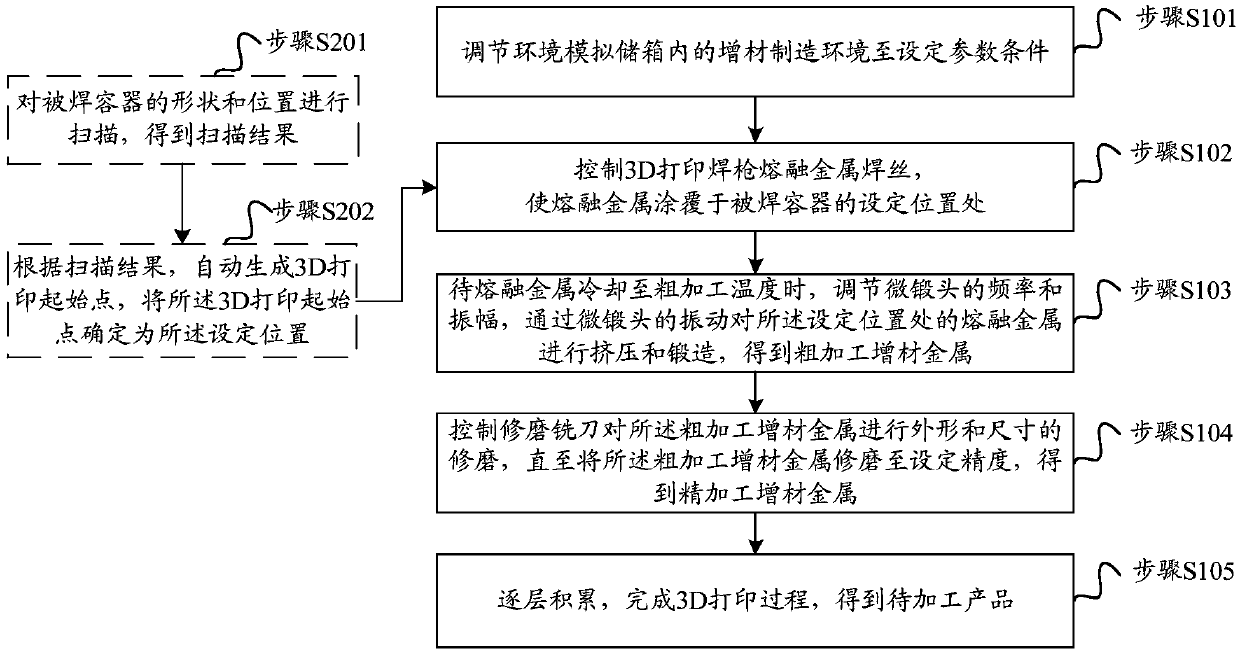

[0051] Such as figure 2 , is a flow chart of the steps of another 3D printing composite material space pressure vessel metal lining described in the embodiment of the present invention. The 3D printing composite space pressure vessel metal lining production method may also include:

[0052] Step S201, scanning the shape and position of the container to be welded to obtain a scanning result.

[0053] Step S202, automatically generate a 3D printing starting point according to the scanning result, and determine the 3D printing starting point as the set position.

Embodiment 3

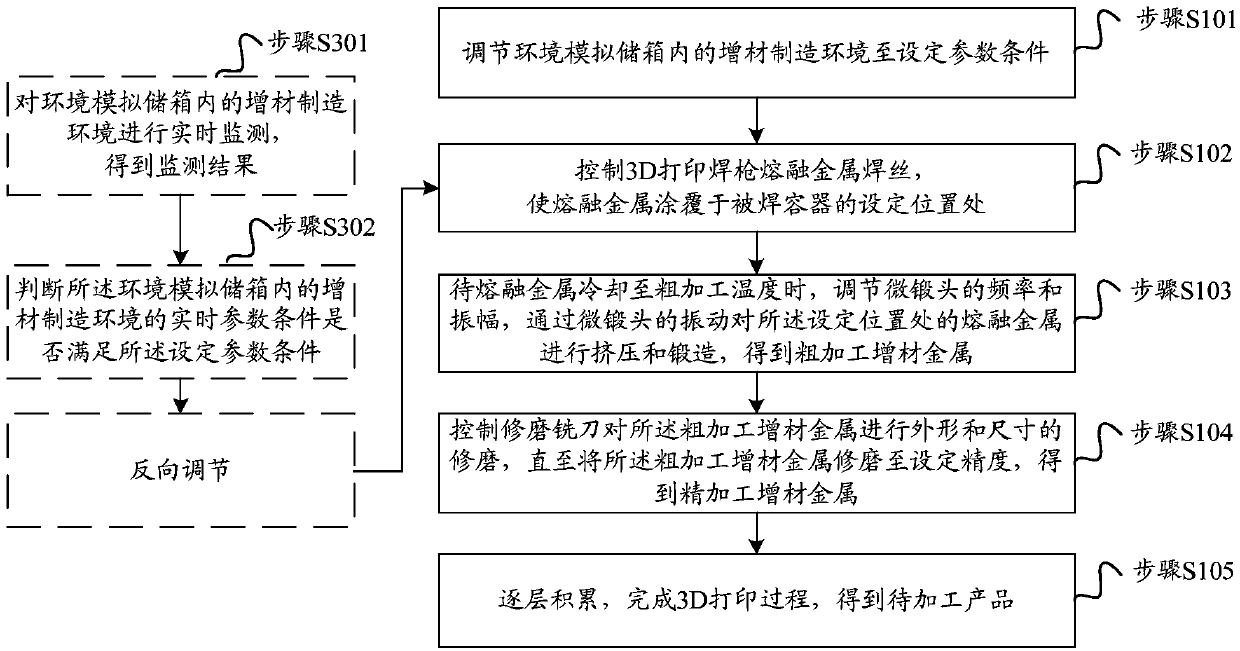

[0055] Such as image 3 , is a flow chart of the steps of another 3D printing composite material space pressure vessel metal lining described in the embodiment of the present invention. The 3D printing composite space pressure vessel metal lining production method may also include:

[0056] In step S301, the additive manufacturing environment in the environment simulation tank is monitored in real time, and the monitoring result is obtained.

[0057] Step S302, according to the monitoring result, it is judged whether the real-time parameter condition of the additive manufacturing environment in the environmental simulation tank satisfies the set parameter condition.

[0058] In this embodiment, if the real-time parameter conditions of the additive manufacturing environment in the environmental simulation storage tank do not meet the set parameter conditions, reverse adjustments (such as reverse heating, reverse cooling, reverse inflation or Reverse operations such as reverse ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com