Photo-curing 3D printer and 3D printing method

A 3D printer and 3D printing technology, applied in the field of 3D printing, can solve the problems of printing tomographic printing failure, elevated curing surface, difficult center material, etc., to improve the success rate of printing, avoid reciprocating motion, and avoid the effect of size change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

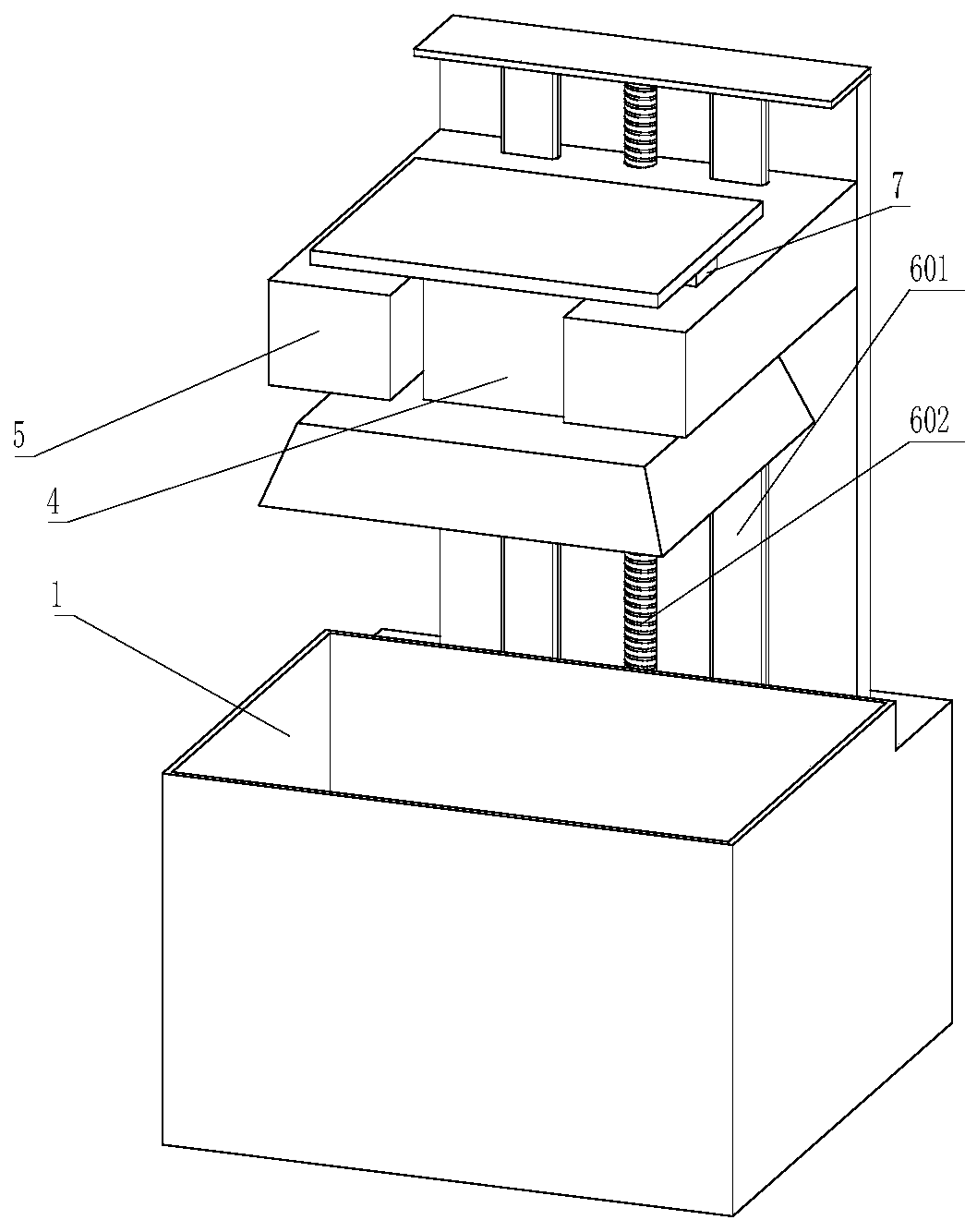

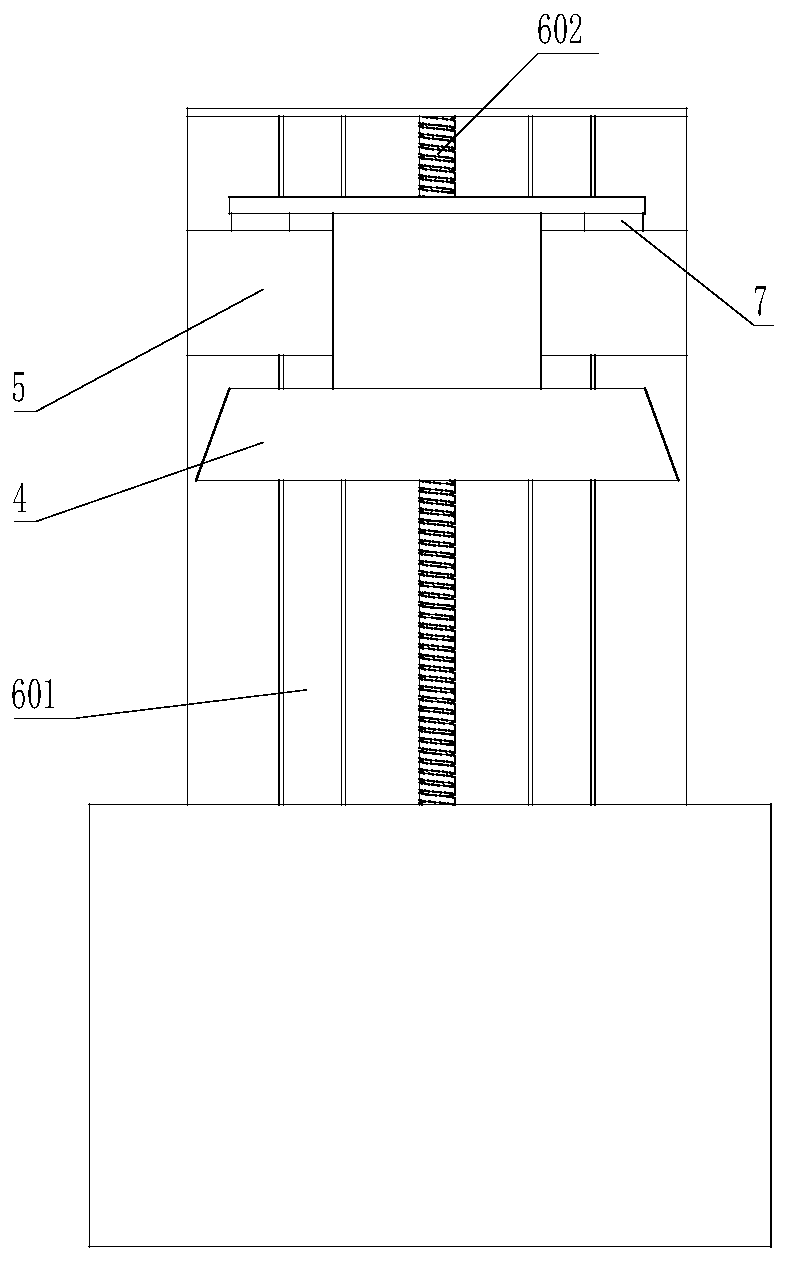

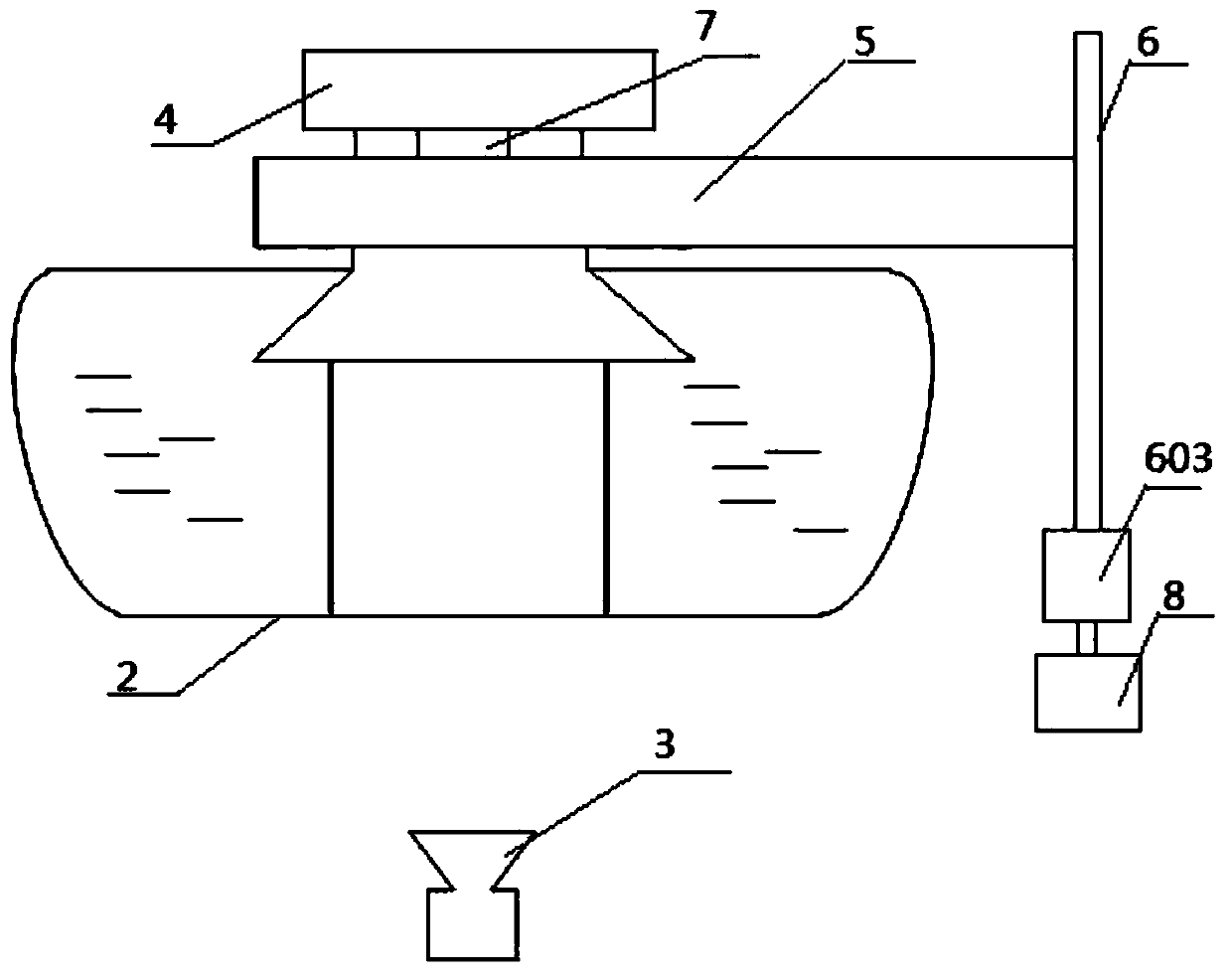

[0039] Such as Figure 1 to Figure 5 As shown, the light-curing 3D printer includes a container 1 filled with photosensitive resin. The bottom of the container 1 is a light-transmitting film 2. The bottom of the container 1 is provided with an optical machine 3. A printing platform 4 is provided above the container 1. The printing platform 4 passes through the platform bracket 5. A lifting mechanism 6 is connected, and the lifting mechanism 6 is electrically connected with a printing control module for controlling the lifting speed. The platform support 5 is provided with a pressure sensor 7 for detecting the pressure of the printing platform 4, and the lifting mechanism 6 is connected with a sensor for detecting the displacement of the lifting mechanism. The displacement detection part is a code disc 8, and the pressure sensor 7 and the displacement detection part are electrically connected to the printing control module.

[0040] The lifting mechanism includes a line rail 60...

Embodiment 2

[0042] Such as Figures 1 to 5 As shown, based on the 3D printer in Embodiment 1, the 3D printing method comprises the following steps:

[0043] Force measurement step: set the expected force S of the light-transmitting film, the expected force S is the maximum draft force that the light-transmitting film 2 can withstand without falling off and rebounding from the solidified surface, and calculate the actual draft of the light-transmitting film in real time The force F enters the speed adjustment step; the force measurement step includes the following sub-steps:

[0044] 1-1: Calculate the gravity G of the printing platform 4;

[0045] 1-2: The pressure sensor 7 reads the current pressure N, and the actual draft force F of the transparent film 2 is the difference between the current pressure N and the gravity G of the printing platform 4 . During the printing process, when the printing platform 4 rises and draws the mold, the pressure detected by the pressure sensor 7 is the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com