Reverse correction method for torsion and bending deformation of blisk blade

A technology of bending deformation and integral blisk, which is applied to the details of milling machine equipment, metal processing equipment, milling machine equipment, etc., can solve the problems of failure to consider the influence of torsion and bending deformation on the machining accuracy of blades, achieve small torsion angle deviation, and improve milling Effect of rigidity and small positional deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

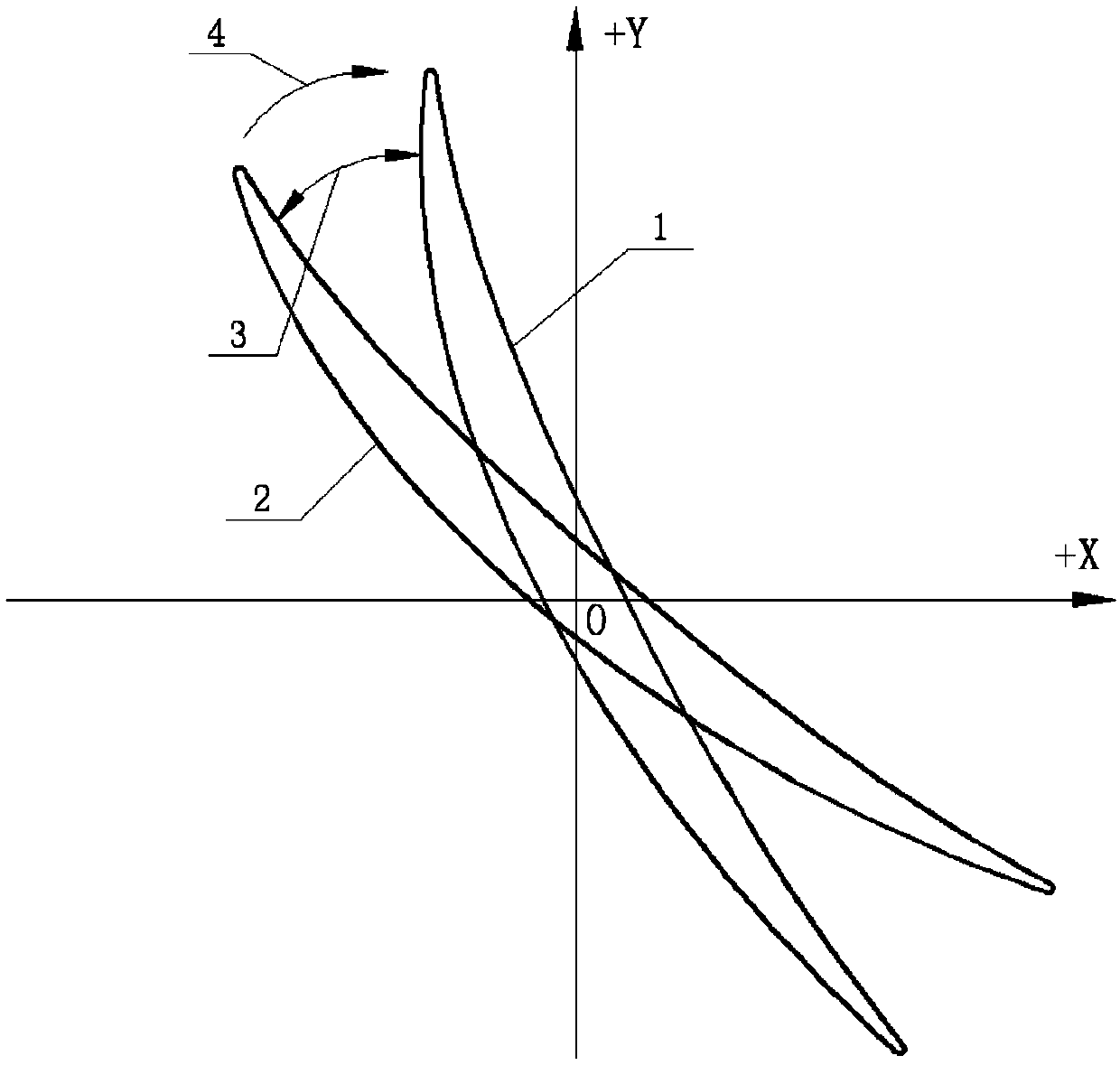

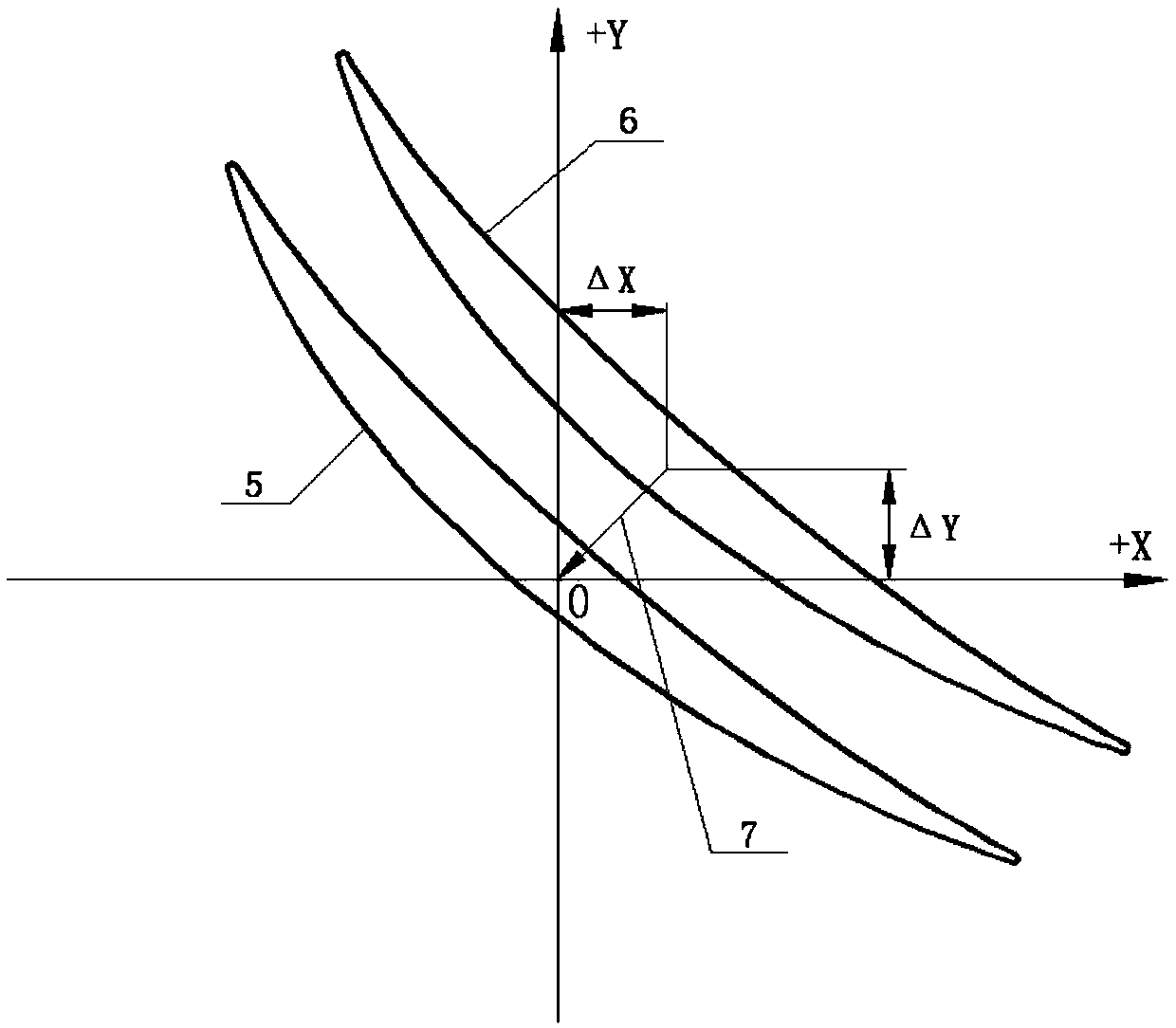

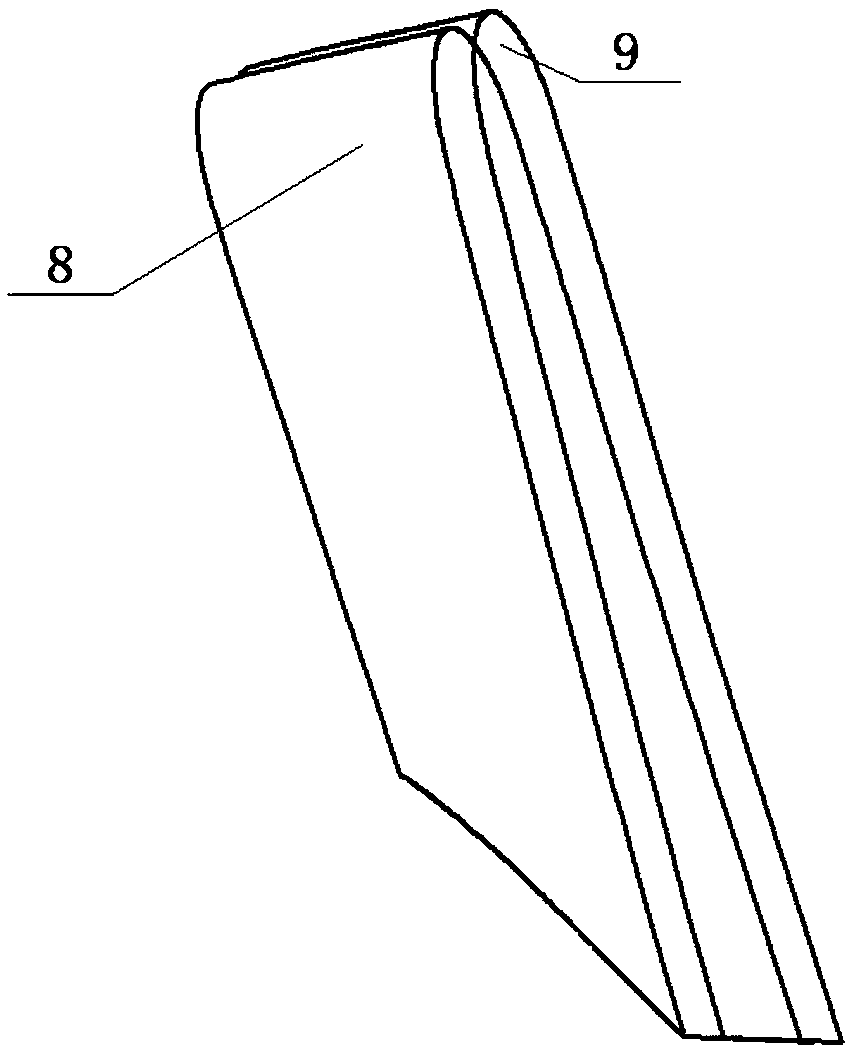

[0035] Such as Figure 1-5The invention is shown for controlling the torsional and bending deformation of a blisk during milling. The overall blisk blade is made of titanium alloy material with relatively low hardness, the blade span length is 133mm, the minimum distance between adjacent blades is about 18mm, and the front and rear edges R is 1.2mm. 7 to blade section S 21 Can be tested. Proceed as follows:

[0036] Step 1: Analyze the deformation characteristics of the blade;

[0037] The overall blisk blade belongs to the cantilever structure, and there is continuity in the deformation of the blade entity. The blade deformation of the overall blisk has the following characteristics: from the blade root to the blade tip, the torsional deformation of the blade increases gradually, the air intake edge twists to the back side of the blade, and the exhaust edge twists to the blade pot side; the bending deformation of the blade gradually increases. Large, leaf pots curved lat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com