Taper thread milling cutter with internal cooling structure

A technology of thread milling cutter and cooling structure, which is applied in the direction of thread cutting tools, manufacturing tools, metal processing equipment, etc., can solve the problems of high manufacturing cost, poor processing quality, and low finish of workpieces, achieve high thread processing accuracy, and eliminate common The effect of poor performance and strong universal interchangeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

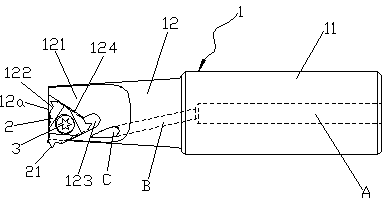

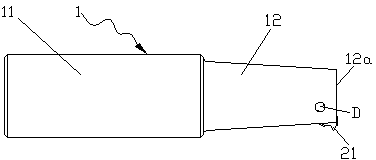

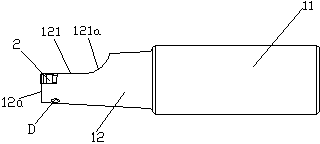

[0022] Figure 1 to Figure 6 Shown is the structural representation of the present invention.

[0023] The reference signs are: main liquid inlet channel A, directional inclined flow channel B, liquid injection port C, threaded mounting hole D, cutter body 1, cylindrical shank 11, tapered column rod 12, front end plane 12a, cut surface Platform 121 , smooth curved surface 121 a , positioning recessed area 122 , extension groove 123 , first side wall 124 , milling insert 2 , cutting edge 21 , and special screw 3 .

[0024] Such as Figure 1 to Figure 6 As shown, the tapered thread milling cutter with internal cooling structure of the present invention includes a tool holder body 1, which is composed of an integrally formed cylindrical handle 11 and a tapered column rod part 12, and the front end of the tapered column rod part 12 The milling s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com