A kind of preparation method of metal single atom catalyst

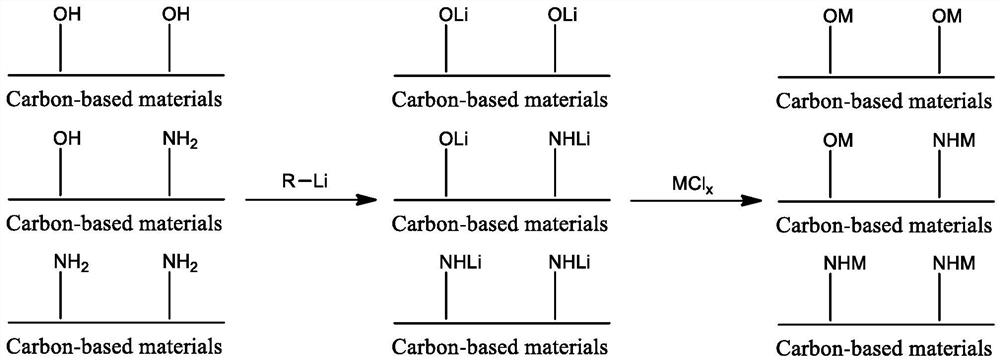

A catalyst and metal technology, applied in the field of preparation of metal single-atom catalysts, can solve problems such as difficulty in controlling metal dispersion, achieve metal atom dispersion and controllable active sites, high metal atom loading concentration, simple and practical preparation method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: the preparation of Ag single-atom catalyst

[0033] Step 1, 1 g of aminated g-C 3 N 4 Add it to 20ml of anhydrous ether, add 0.25ml of 1.6M methyllithium ether solution dropwise to it under nitrogen atmosphere, stir while adding, keep the temperature of the system at -78°C during the dropwise addition, and place in nitrogen atmosphere after the dropwise addition Stir and react at 25°C for 8 hours, then filter, and the filter cake is washed and dried with anhydrous ether to obtain an intermediate product;

[0034] Step 2, disperse the obtained intermediate product and 65 mg AgCl in 20 ml of anhydrous ether under a nitrogen atmosphere, and stir and react at 25° C. for 8 hours to obtain a mixture of Ag single-atom catalyst and lithium chloride;

[0035] In step 3, the mixture described in step 2 is fully dissolved in water and then filtered, and the filter cake is dried at 50° C. to obtain the Ag single-atom catalyst with a loading capacity of 4%.

[0036] ...

Embodiment 2

[0040] Embodiment 2: the preparation of Cu single-atom catalyst

[0041] Step 1, add 1g of hydroxylated fullerene to 20ml of anhydrous n-hexane, add 0.5ml of 2.5M n-butyl lithium ether solution dropwise to it under nitrogen atmosphere, stir while adding, and maintain the system during the dropping process The temperature is -78°C. After the dropwise addition, stir and reflux at 60°C under a nitrogen atmosphere for 6 hours, then filter, and the filter cake is washed and dried with anhydrous n-hexane to obtain an intermediate product;

[0042] Step 2, disperse the obtained intermediate product and 124 mg CuCl in 20 ml of anhydrous n-hexane under a nitrogen atmosphere, and stir and reflux at 60 ° C for 6 h to obtain a mixture of Cu single-atom catalyst and lithium chloride;

[0043] In step 3, the mixture described in step 2 is fully dissolved in water and then filtered, and the filter cake is dried at 100° C. to obtain the Cu single-atom catalyst with a loading capacity of 7%. ...

Embodiment 3

[0047] Embodiment 3: the preparation of Co single-atom catalyst

[0048] Step 1, add 1g of graphene oxide to 20ml of anhydrous furan, add 0.34ml of 16% tert-butyl lithium pentane solution dropwise to it under nitrogen atmosphere, stir while adding, and maintain the system temperature at -78°C during the dropping process °C, after the dropwise addition, stir and reflux at 80 °C for 4 hours under a nitrogen atmosphere, then filter, and the filter cake is washed and dried with anhydrous furan to obtain an intermediate product;

[0049] Step 2, the intermediate product obtained with 66mg CoCl 2 Disperse in 20ml of anhydrous furan under a nitrogen atmosphere, stir and reflux at 80°C for 4h to obtain a mixture of Co single-atom catalyst and lithium chloride;

[0050] In step 3, the mixture described in step 2 is fully dissolved in water and then filtered, and the filter cake is dried at 150° C. to obtain the Co single-atom catalyst, wherein the loading amount is 2%.

[0051] The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com