Visible light waveband metamaterial perfect absorber and self-assembling preparation method thereof

A perfect absorption and metamaterial technology, applied in the field of visible light band metamaterial perfect absorber and its self-assembly preparation, can solve the problems of low average absorption rate and narrow working bandwidth, and achieve effective regulation of characteristics and stable and reliable self-assembly method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

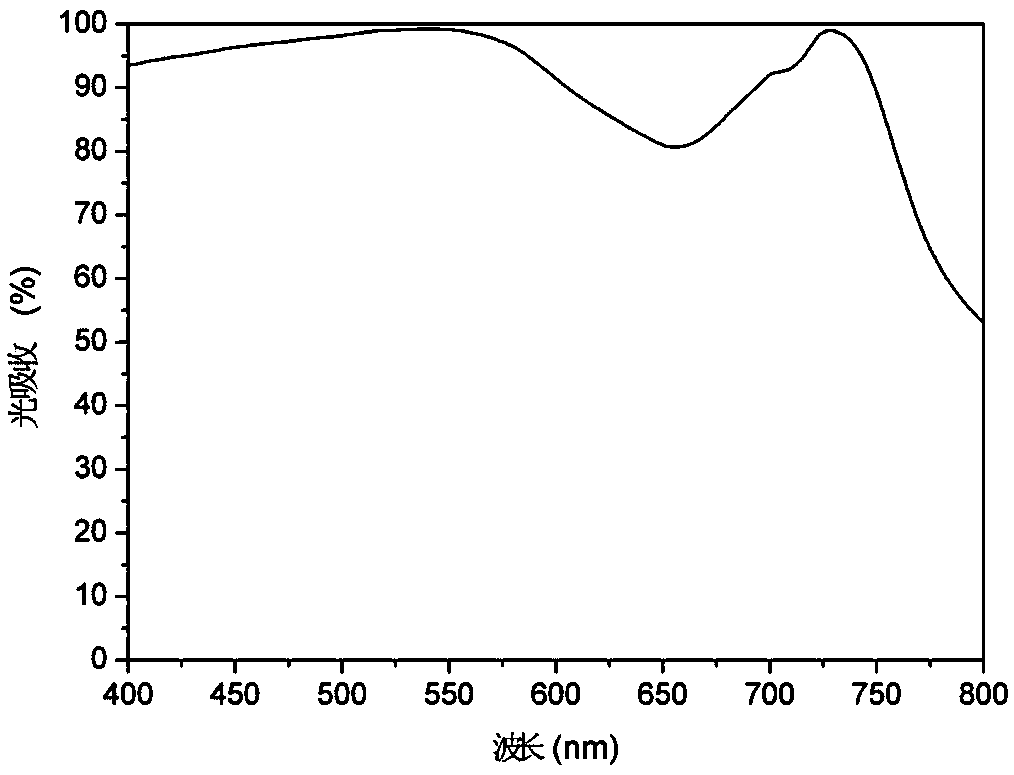

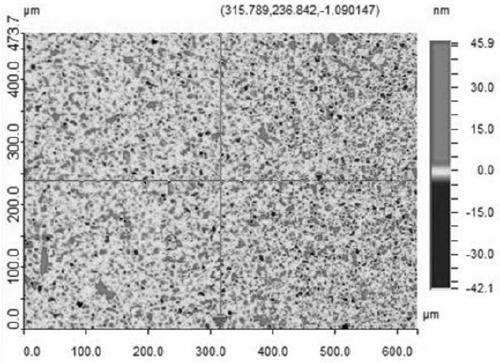

[0019] Place the clean substrate in the vacuum coating system, and plate 80nm thick Al film and 30nm thick SiO from bottom to top respectively. 2 dielectric film, which will subsequently be pre-coated with Al-SiO 2 The film substrate was vertically immersed in a 10mM concentration of positively charged colloidal Aunanoctahedron solution for 36 hours to obtain the upper layer of Au nanoctahedron with a coverage rate of 22%, washed and dried, and finally obtained the desired metamaterial absorber and carried out related structure and performance tests. Test characterization.

Embodiment 2

[0021] Place the clean substrate in a vacuum coating system, and plate a 60nm thick Al film and a 10nm thick SiO film from bottom to top. 2 dielectric film, which will subsequently be pre-coated with Al-SiO 2 The film substrate was vertically immersed in a 10mM concentration of positively charged colloidal Aunanoctahedron solution for 24 hours to obtain the upper layer of Au nanoctahedron with a coverage rate of 17%. After washing and drying, the desired metamaterial absorber was finally obtained and the relevant structures and properties were analyzed. Test characterization.

Embodiment 3

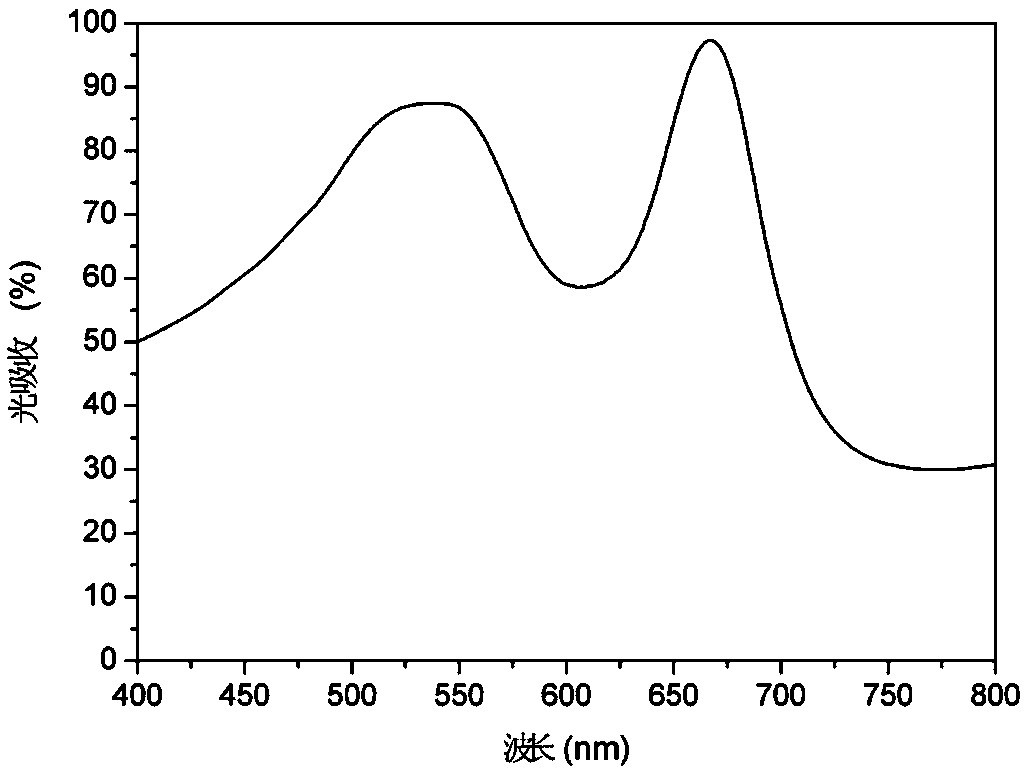

[0023] Place the clean substrate in a vacuum coating system, and plate a 70nm thick Al film and a 50nm thick SiO film from bottom to top. 2 dielectric film, which will subsequently be pre-coated with Al-SiO 2 The film substrate was vertically dipped in a colloidal Aunanoctahedron solution with a positive charge on the surface at a concentration of 10 mM for 60 hours to obtain the upper layer of Au nanoctahedron with a coverage rate of 30%, washed and dried, and finally obtained the desired metamaterial absorber and carried out related structure and performance tests. Test characterization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com