Test method for dynamic anisotropy properties of solids under high temperature and medium-low strain rate loading

Anisotropy and characteristic testing technology, applied in the field of material mechanics, can solve problems such as the inability to quantitatively determine and capture the deformation and failure characteristics of the rock surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

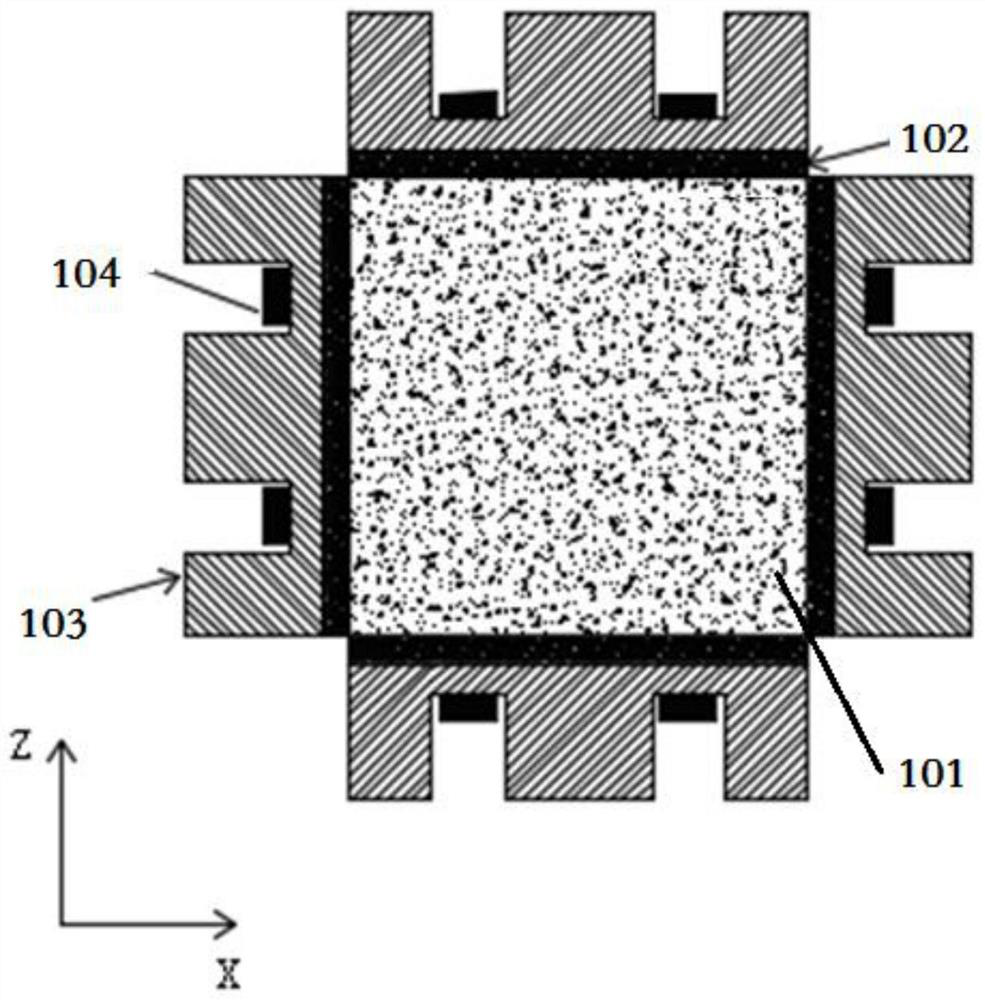

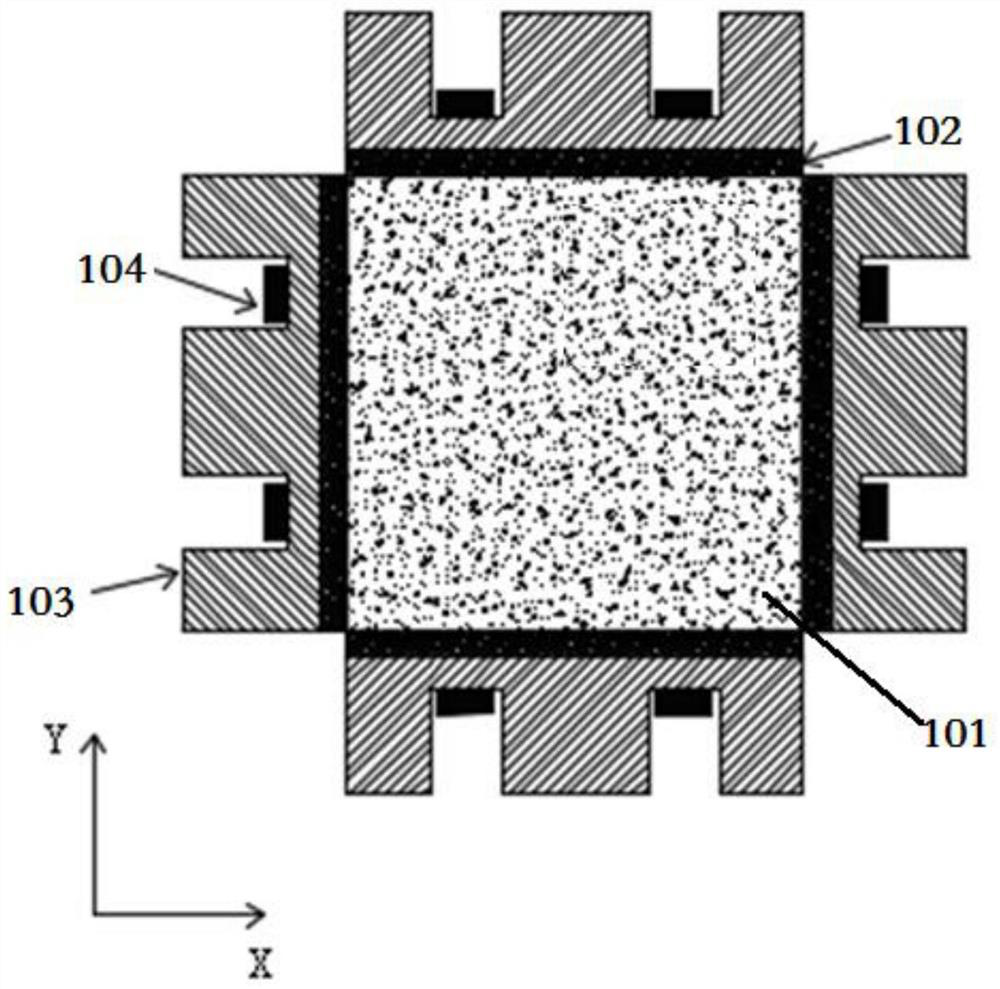

[0047] The present invention will be further described below in conjunction with the accompanying drawings.

[0048] The present invention is based on a true triaxial test system with a dynamic and static integration of medium and low strain rates, and can realize 10 -3 the s -1 to 10 1 the s -1 strain rate loading in the range.

[0049]The present invention is based on a true triaxial test system with medium and low strain rate dynamic and static integration. Aiming at the difficulty in obtaining test data, especially the phenomenon that the internal dynamic mechanical parameters of the sample cannot be monitored, the present invention provides a solid dynamic measurement system under high temperature and medium and low strain rate loading. Test methods for item heterogeneity and non-uniformity.

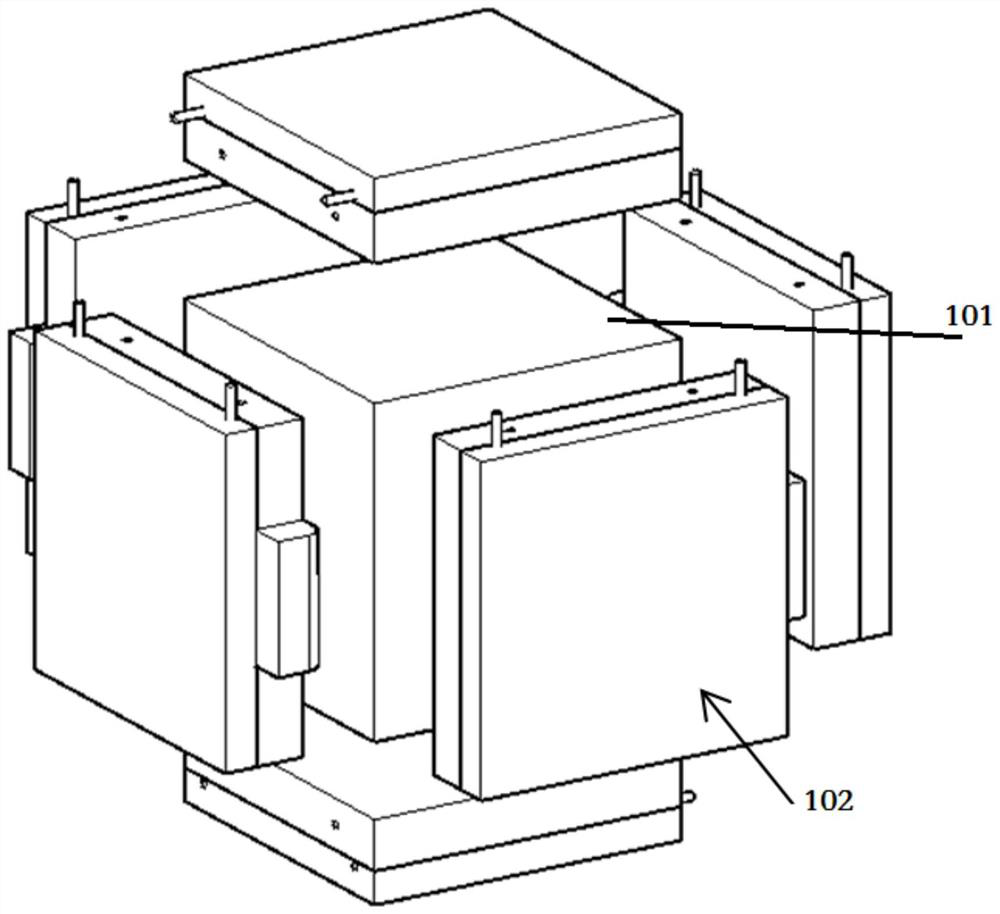

[0050] The device of the present invention includes a heating plate 102 , a rigid pressing plate 103 and an acoustic emission sensor 104 .

[0051] The heating plate 102 is att...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com