Enveloping type reinforcing method of underground structure

An underground structure and enveloping technology, which is applied in underground chambers, earthwork drilling, wellbore lining, etc., can solve the problems of large waste discharge, long construction period, and poor quality of reinforcement, and achieve high operating efficiency, Solve the impact of tunnel safety and strengthen the effect of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

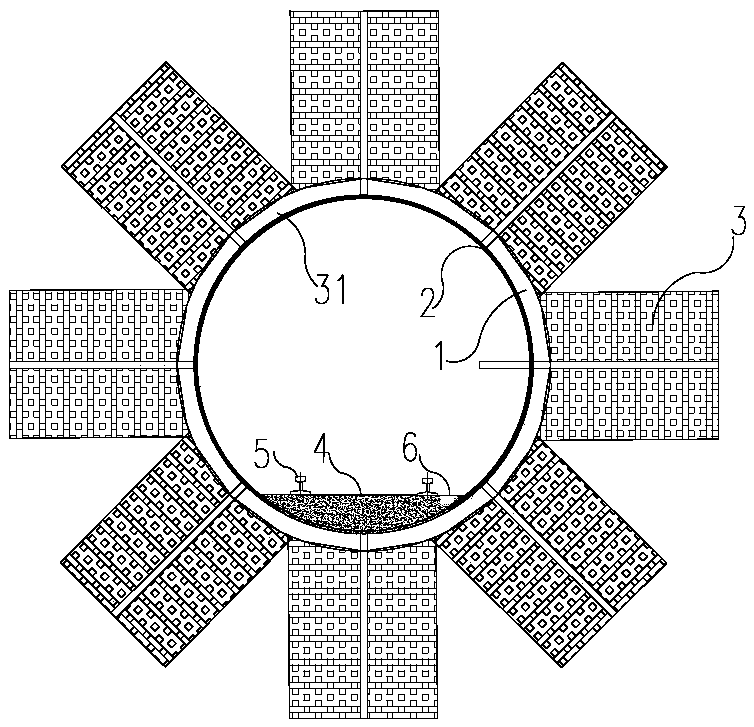

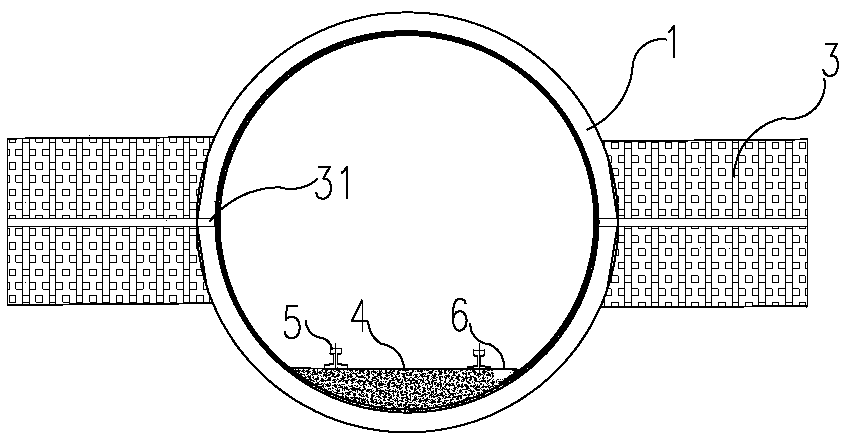

[0033] figure 1 Shown is a schematic diagram of an enveloping reinforcement method for underground structures, and the formed jet grouting reinforcements are continuously distributed. It can be seen from the figure that the enveloping reinforcement structure of the tunnel lining and the underground structure is composed of the tunnel lining and the underground Structural structure 1, steel plate lining 2 and displacement jet grouting reinforcement 3 distributed in the formation outside the tunnel.

[0034] The high-pressure jet grouting piles 3 distributed along the outer circumference of the tunnel are distributed in a continuous overlapping manner, which has the effects of water stop and uniform ground reinforcement.

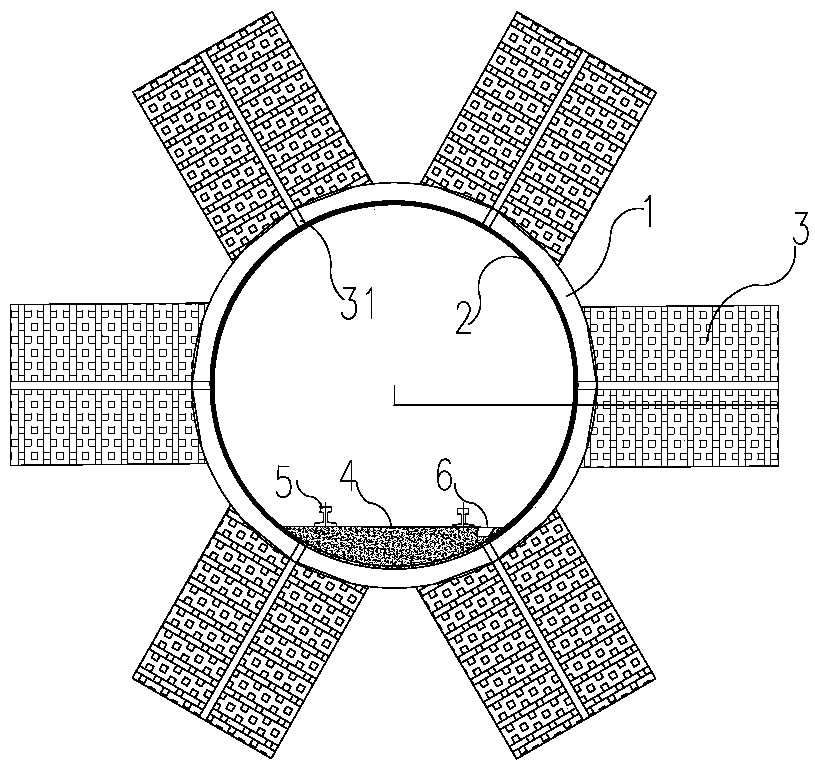

[0035] figure 2 In th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com