Method for manufacturing flange bolting-welding hybrid connection assembly type beam-column joints

A hybrid connection, beam-column joint technology, applied in the direction of building, building structure, etc., can solve the problems of high requirements for component and joint machining accuracy, inconvenient floor installation, and difficult to meet, etc., to reduce the possibility of fire, convenient and convenient. The effect of floor installation and easy positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

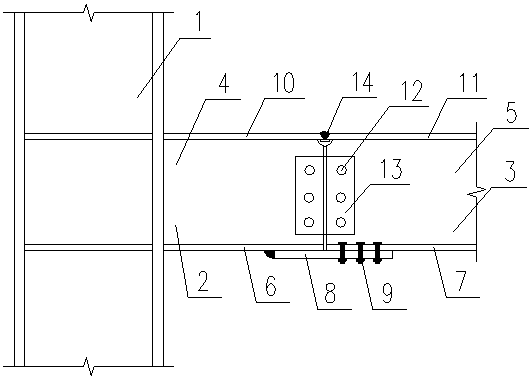

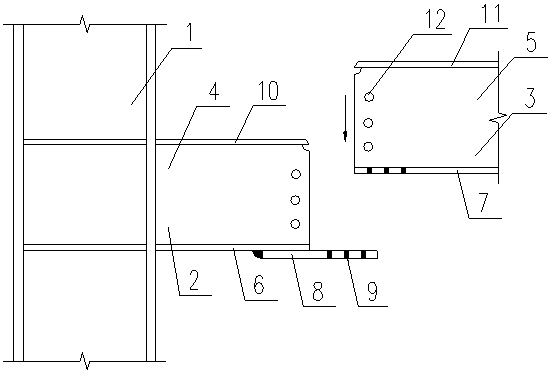

[0046] A flange bolt-welding hybrid connection assembled beam-column joint, comprising a steel column 1, a cantilever beam 2, a frame beam 3, a splicing plate 8, and a node plate 13, the steel beam is composed of a cantilever beam 2 and a frame beam 3, and a steel column 1 , Steel beams (2, 3) are made of H-beam, the section size of steel beams (2, 3) is H300 × 160 × 8 × 10mm, the section size of steel column 1 is H250 × 250 × 9 × 14mm, and the steel is Q345B. Bolts (9, 12) are made of 10.9-grade M20 friction type high-strength bolts. According to the "Code for Design of Steel Structures" (GB20017-2003), the pre-tightening force of the high-strength bolts is P=155kN, and the friction coefficient is 0.5.

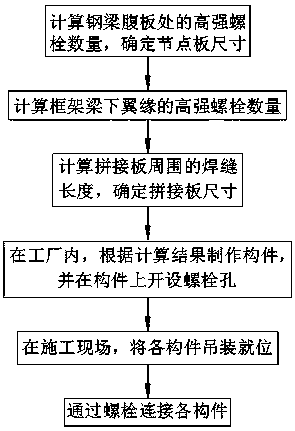

[0047] A method for manufacturing a flanged-welded hybrid-connected assembled beam-column joint, comprising the following steps:

[0048] (1) Preliminarily assume the width b of the splice plate 8 arranged on the lower flange of the steel beam (2, 3) p =160+4×10=200mm, thick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com