Nb+Cr component system sleeve hot-rolled steel strip and preparation process thereof

A preparation process and casing technology, which is applied in the field of Nb+Cr composition hot-rolled steel strip for casing and its preparation technology, can solve problems such as the inability of products to meet demand, achieve improved quality advantages, ensure comprehensive performance, and broad application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

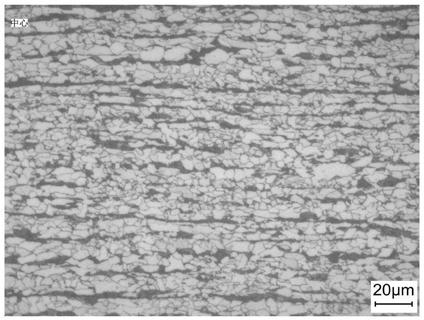

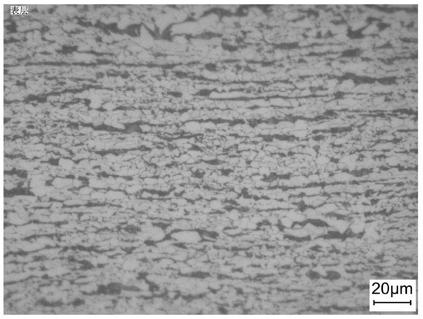

Image

Examples

Embodiment 1

[0023] Converter: Tapping temperature ≥ 1620°C, to ensure that the composition and temperature are coordinated and tapped; if the tapping temperature of the new tapping hole is based on the upper temperature limit, the tapping temperature should be increased by 10-15°C as appropriate. Add ferro-aluminum, ferrosilicon, ferromanganese, etc. for deoxidation alloying, and add ferrochrome to adjust the composition.

[0024] Refining: LF furnace slagging and desulfurization, and adding alloys such as aluminum iron, ferrosilicon, ferromanganese, and ferroniobium to adjust to the target composition range. Calcium treatment is performed after LF treatment, and the soft blowing time is guaranteed to be more than 8 minutes after calcium treatment.

[0025] Continuous casting: The liquidus temperature of this steel is 1514°C, the superheat of molten steel in the first tundish is 25-40°C, and the superheat of molten steel in other heats is 15-30°C.

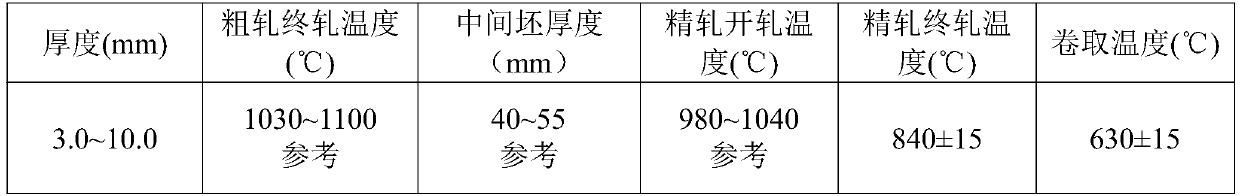

[0026] Controlled rolling and controll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com