Scum fishing and smashing machine

A pulverizer and scum technology, applied in the field of machinery, can solve the problems of mechanical treatment of sundries, inconvenient transportation and effective waste utilization, etc., and achieve the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

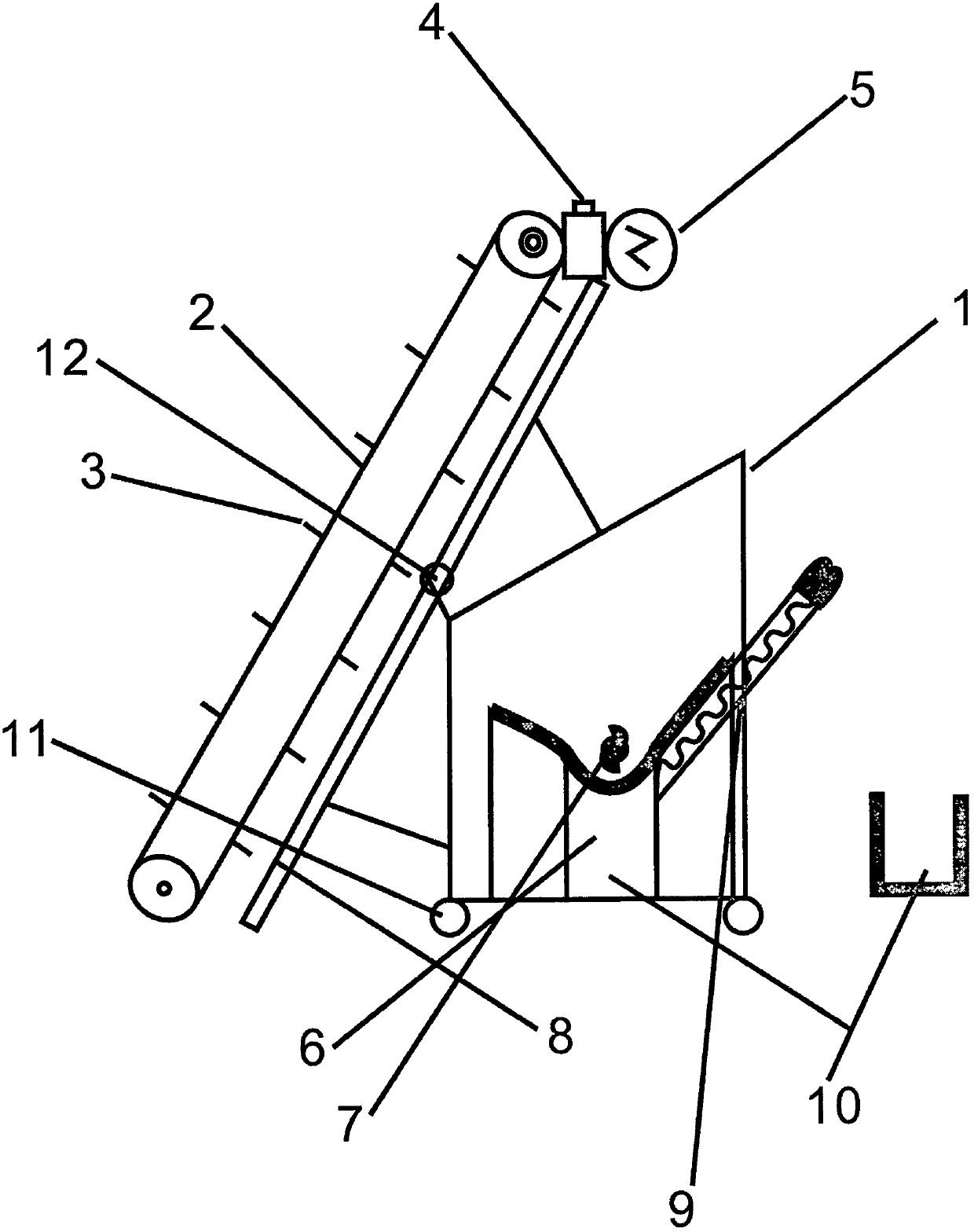

[0012] The scum salvage pulverizer of the present invention is through 1, bracket; 2, rubber belt; 3, a plurality of grasping claws; 4, reducer; 8. Adjustable slideway; 9. Compacting auger; 10. Slag truck or ship; 11. Mobile rail wheel; 12. It is composed of adjustable support points.

[0013] Described 2 rubber belts are to use the belt of certain width to be wound into the rotation belt of two-way operation, and more than 3 grasping claws are housed on the belt, and the claws will inevitably claw the floating objects to the belt with the turning top and then backward 6 crushing slides during transshipment. road.

[0014] Described 6 shredding chute is to send to 10 slag trucks or ship after the sundries that fall into are shredded by 7 augers and transported to 9 compacting augers for compaction.

[0015] The 8 adjustable slideways are for supporting the belt and adjusting the up and down distance of the belt so that the azimuth can be adjusted.

[0016] Described 11 movin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com