Acrylic color changing film manufacturing method

A manufacturing method, acrylic technology, applied in the direction of film/sheet adhesive, adhesive type, pressure-sensitive film/sheet, etc., can solve the problems of poor metal adhesion and decreased appearance of color-changing film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

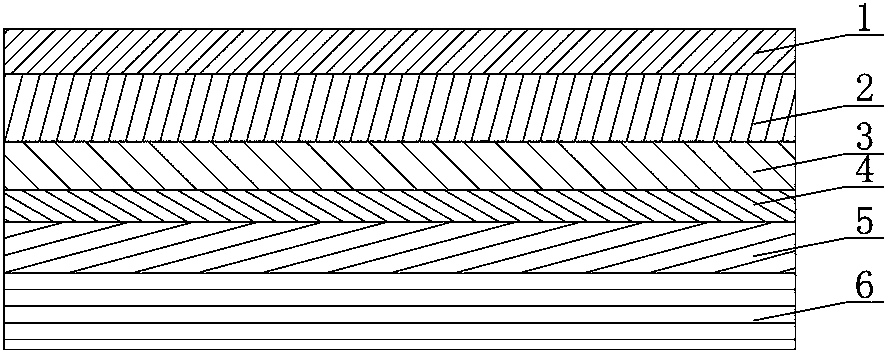

Image

Examples

Embodiment 1

[0040] A method for manufacturing an acrylic color-changing film, comprising the following steps:

[0041] (a) Take a substrate layer, take ethyl acrylate, methyl methacrylate, 2-hydroxyethyl methacrylate, 2-aminoethyl methacrylate, ethyl acetate, AIBN initiator and mix them at a ratio of 35:50 : 5:1:140:1 weight ratio put into the blender and stir evenly to form mixture A;

[0042] (b) Pour 40% by weight of the mixture A into the reactor A, then raise the temperature of the reactor A to 80 degrees Celsius, and then pour the remaining 60% by weight of the mixture A at a uniform speed within 120 minutes Dropwise into the reactor A, after the 60% by weight of the mixture A is added dropwise, the reactor A is incubated for 90 minutes;

[0043] (c) Take the AIBN initiator and ethyl acetate and stir them evenly at a weight ratio of 0.1:60 to form a mixture B, the weight ratio of the mixture B to the mixture A is 1:3, uniformly and uniformly to the said mixture within 50 minutes A...

Embodiment 2

[0059] A method for manufacturing an acrylic color-changing film, comprising the following steps:

[0060] (a) Take a substrate layer, take ethyl acrylate, methyl methacrylate, 2-hydroxyethyl methacrylate, 2-aminoethyl methacrylate, ethyl acetate, AIBN initiator and press 37.5:52.5 : The weight ratio of 7.5:3:145:1.5 is put into the blender and stirred evenly to form mixture A;

[0061] (b) Pour 40% by weight of the mixture A into the reactor A, then raise the temperature of the reactor A to 80 degrees Celsius, and then pour the remaining 60% by weight of the mixture A at a uniform speed within 120 minutes Dropwise into the reactor A, after the 60% by weight of the mixture A is added dropwise, the reactor A is incubated for 90 minutes;

[0062] (c) Take the AIBN initiator and ethyl acetate and stir them evenly at a weight ratio of 0.55:70 to form a mixture B, the weight ratio of the mixture B to the mixture A is 1:3.5, uniformly and uniformly to the said mixture within 50 min...

Embodiment 3

[0078] A method for manufacturing an acrylic color-changing film, comprising the following steps:

[0079] (a) Take a base material layer, take ethyl acrylate, methyl methacrylate, 2-hydroxyethyl methacrylate, 2-aminoethyl methacrylate, ethyl acetate, AIBN initiator and press 40:55 : 10:5:150:2 weight ratio put into the blender and stir evenly to form mixture A;

[0080] (b) Pour 40% by weight of the mixture A into the reactor A, then raise the temperature of the reactor A to 90 degrees Celsius, and then put the remaining 60% by weight of the mixture A at a uniform speed within 125 minutes Dropwise into the reactor A, after the 60% by weight of the mixture A is added dropwise, the reactor A is incubated for 95 minutes;

[0081] (c) Take the AIBN initiator and ethyl acetate and stir them evenly at a weight ratio of 1:80 to form a mixture B, the weight ratio of the mixture B to the mixture A is 1:4, uniformly and evenly to the said mixture within 55 minutes Add the mixture B d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com