Microporous oriented polylactic acid thin film

A microporous, polylactic acid technology, applied in other household appliances, synthetic resin layered products, chemical instruments and methods, etc., can solve problems such as affecting film performance and increasing cost, and achieve the effect of simple processing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

[0090] As shown in Table 1, laminate the original film and various auxiliary materials. The lamination method is as follows: use butyl rubber tape (leakage-proof layer) on one side of the original film to enclose a 4cm×4cm space, and set a liquid layer in this space. A protective layer is then placed over the liquid layer and the anti-leakage layer.

[0091] Then, a microporous oriented polylactic acid film was prepared by stretching using a KARO-IV biaxial stretching machine produced by Bruckner Company. When stretched, the protective layer side of the laminated film faces down.

[0092] Preheating temperature, preheating time, stretching temperature, stretching method (unidirectional, sequential bidirectional, simultaneous bidirectional), stretching ratio (MD×TD), stretching rate, heat treatment temperature and time are shown in Table 1.

[0093] The single surface of the obtained microporous oriented polylactic acid film has a microporous layer structure, and Table 1 list...

Embodiment 5

[0095] As shown in Table 1, laminate the original film and various auxiliary materials. The lamination method is as follows: use butyl rubber tape (leakage-proof layer) on one side of the original film to enclose a 4cm×4cm space, and set a liquid layer in this space. A protective layer is then placed over the liquid layer and the anti-leakage layer.

[0096] Then, a microporous oriented polylactic acid film was prepared by stretching using a KARO-IV biaxial stretching machine produced by Bruckner Company. When stretched, the protective layer side of the laminated film faces upward.

[0097] Preheating temperature, preheating time, stretching temperature, stretching method (unidirectional, sequential bidirectional, simultaneous bidirectional), stretching ratio (MD×TD), stretching rate, heat treatment temperature and time are shown in Table 1.

[0098] The single surface of the obtained microporous oriented polylactic acid film has a microporous layer structure, and Table 1 li...

Embodiment 6~11

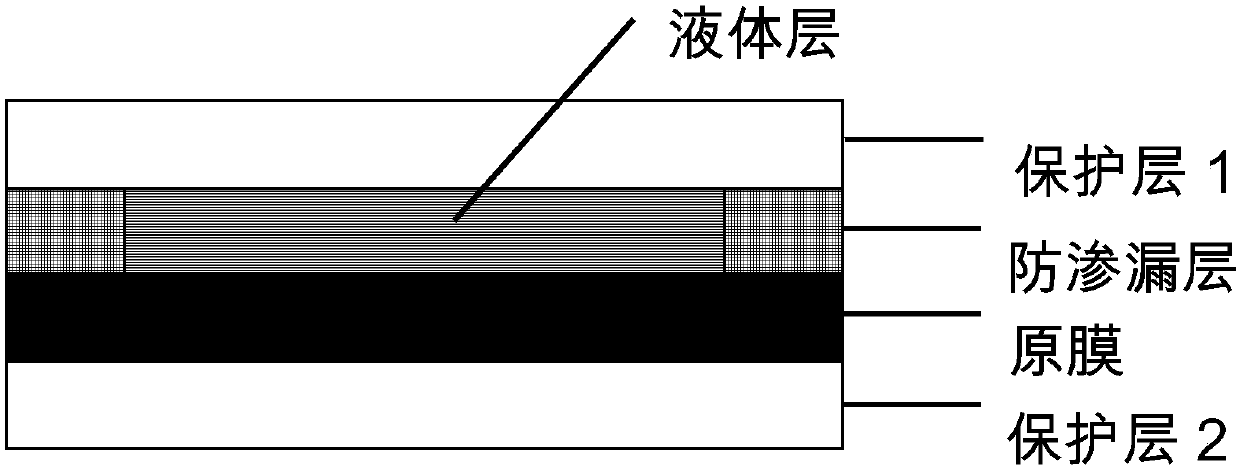

[0104] As shown in Table 2, laminate the original film and various auxiliary materials. The lamination method is as follows: use butyl rubber tape (leakage-proof layer) on one side of the original film to enclose a 4cm×4cm space, and set a liquid layer in this space. Then a protective layer 1 is set above the liquid layer and the anti-leakage layer, and then a protective layer 2 is set on the other side of the original film.

[0105] Then, a microporous oriented polylactic acid film was prepared by stretching using a KARO-IV biaxial stretching machine produced by Bruckner Company. When stretching, the protective layer 1 side of the laminated film faces upward.

[0106] Preheating temperature, preheating time, stretching temperature, stretching method (unidirectional, sequential bidirectional, simultaneous bidirectional), stretching ratio (MD×TD), stretching rate, heat treatment temperature and time are shown in Table 2.

[0107] A single surface of the obtained microporous o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com