Polyethylene composition used for geomembrane

A technology of polyethylene and composition, which is applied in the field of polyethylene composition for geomembrane, which can solve the problems of product quality and safety hazards, stress cracking of geomembrane, and the failure of normal batch production by downstream production enterprises, and achieve excellent stress cracking resistance. And anti-aging performance, the effect of meeting the requirements of production and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

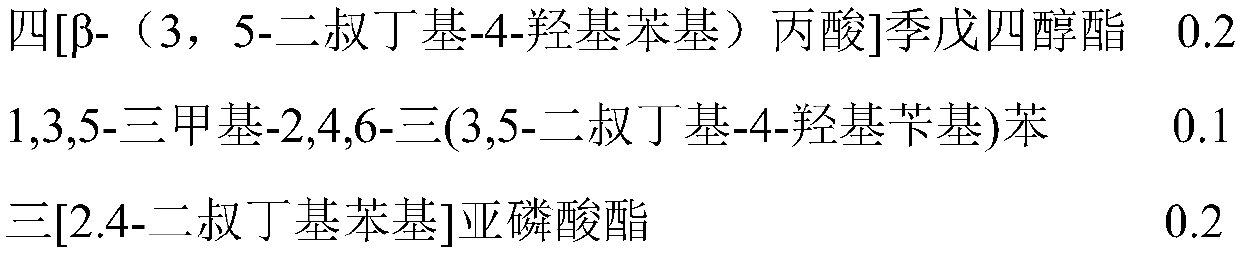

[0023] The proportion of polyethylene composition for geomembrane is as follows:

[0024] High-density polyethylene resin 70 (parts by mass, the same below)

[0025] Linear Low Density Polyethylene Resin 30

[0026] additive:

[0027]

[0028]

[0029] Among them, the density of high-density polyethylene resin is 0.949g / cm 3 , a melt flow rate of 0.4 g / 10 min (190° C., 5.0 kg weight). The density of linear low density polyethylene resin is 0.914g / cm 3 , a melt flow rate of 3.0 g / 10 min (190° C., 2.16 kg weight).

[0030] Specific preparation method: After mixing high-density polyethylene resin, linear low-density polyethylene resin and additives in a high-speed mixer for 5 minutes, the uniformly mixed material is added to a twin-screw extruder for melting, plasticization, extrusion, The composition is obtained after granulation and drying. Wherein, the aspect ratio of the screw of the twin-screw extruder is 25, the diameter of the screw is 35mm, and the processing ...

Embodiment 2

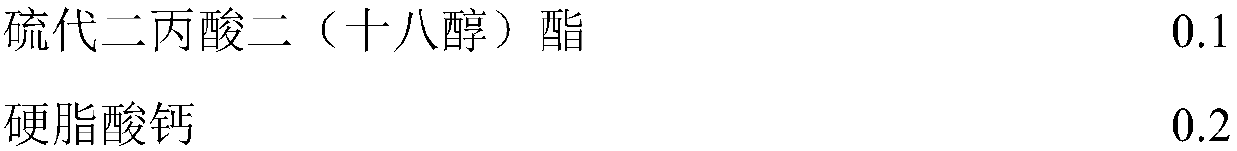

[0033] The proportion of polyethylene composition for geomembrane is as follows:

[0034] High-density polyethylene resin 80 (parts by mass, the same below)

[0035] Linear Low Density Polyethylene Resin 20

[0036] additive:

[0037]

[0038] Among them, the density of high-density polyethylene resin is 0.948g / cm 3 , a melt flow rate of 0.3 g / 10 min (190° C., 5.0 kg weight). The density of linear low density polyethylene resin is 0.918g / cm 3 , a melt flow rate of 2.0 g / 10 min (190° C., 2.16 kg weight).

[0039] Specific preparation method: After mixing high-density polyethylene resin, linear low-density polyethylene resin and additives in a high-speed mixer for 5 minutes, the uniformly mixed material is added to a twin-screw extruder for melting, plasticization, extrusion, The composition is obtained after granulation and drying. Wherein, the aspect ratio of the screw of the twin-screw extruder is 33, the diameter of the screw is 45mm, and the processing temperature ...

Embodiment 3

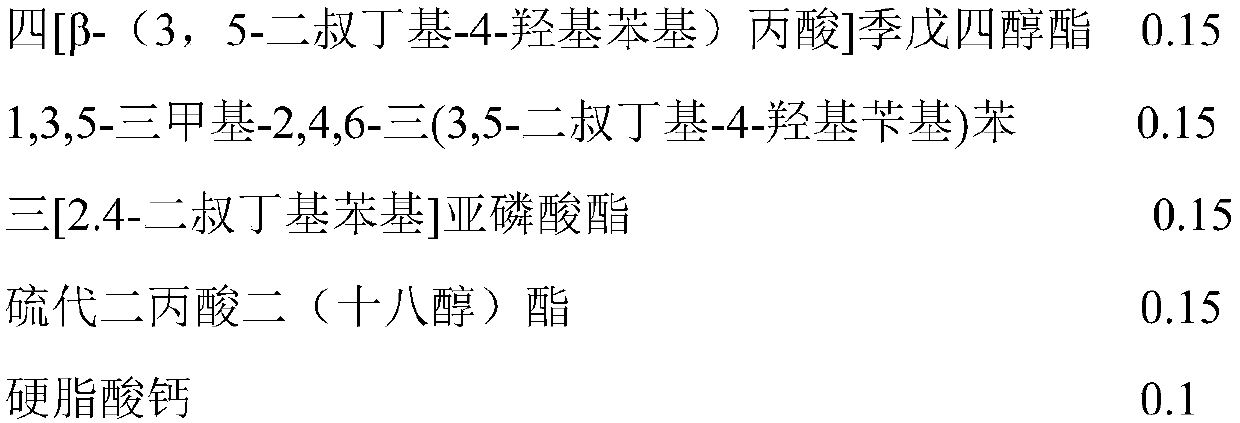

[0042] The proportion of polyethylene composition for geomembrane is as follows:

[0043] High-density polyethylene resin 90 (parts by mass, the same below)

[0044] Linear Low Density Polyethylene Resin 10

[0045] additive:

[0046]

[0047] Among them, the density of high-density polyethylene resin is 0.952g / cm 3 , the melt flow rate is 0.2g / 10min (190°C, 5.0kg weight). The density of linear low density polyethylene resin is 0.922g / cm 3 , a melt flow rate of 1.0 g / 10 min (190° C., 2.16 kg weight).

[0048] Specific preparation method: After mixing high-density polyethylene resin, linear low-density polyethylene resin and additives in a high-speed mixer for 5 minutes, the uniformly mixed material is added to a twin-screw extruder for melting, plasticization, extrusion, The composition is obtained after granulation and drying. Wherein, the aspect ratio of the screw of the twin-screw extruder is 30, the diameter of the screw is 35mm, and the processing temperature is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com