Preparation method of odor-less fast-dry alkyd resin

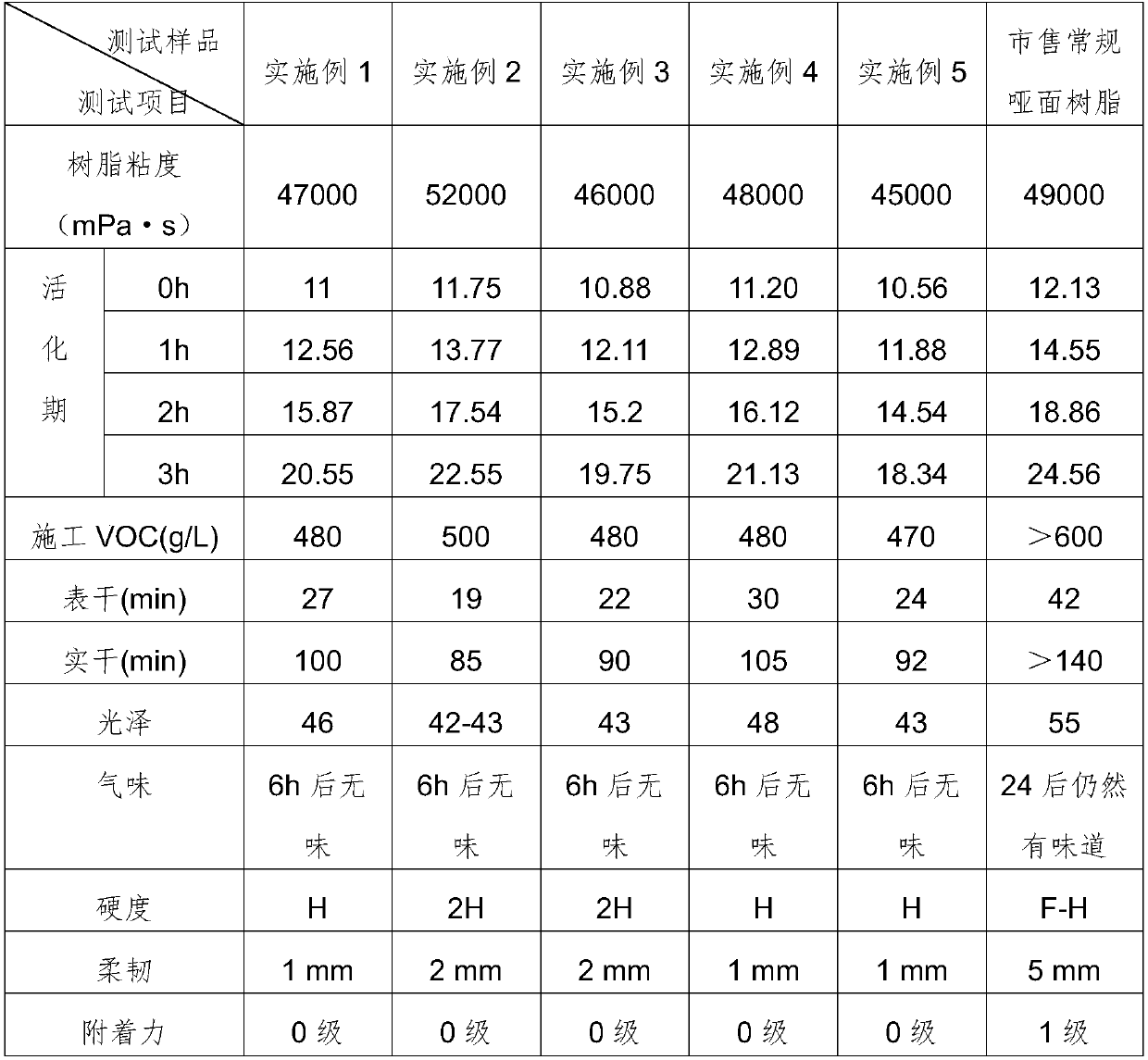

An alkyd resin and deodorizing technology, applied in coatings, polyurea/polyurethane coatings, etc., can solve the problems of long curing time, large odor residue, hard and flexible coating film, etc., and achieve good matting performance and fast deodorization Excellent speed and viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Add 10.73 parts of soybean oleic acid, 2.13 parts of benzoic acid, 9.15 parts of pentaerythritol, 0.10 parts of hypophosphorous acid, and 2.86 parts of refluxed xylene into the reactor in sequence, and slowly raise the temperature to 105°C, start stirring, continue to heat up to 210°C, and keep warm until Acid value ≤15mgKOH / g. Cool down to 150°C, add 10.73 parts of castor oil, 3.41 parts of glycerin, 26.32 parts of phthalic anhydride and 8.44 parts of trimethylolpropane, start stirring, continue to heat up to 170°C, keep warm for 1 hour, and slowly heat up to 200°C within 4 hours. ℃-220℃ heat preservation reaction until the acid value ≤ 12mgKOH / g, lower the temperature to below 145℃, dilute with 26.13 parts of xylene, continue to stir for 30min, filter and discharge the material, and obtain the net taste quick-drying alkyd resin 1. The measured solid content of clean-flavored quick-drying alkyd resin 1 is 70.3%, and the viscosity (25°C) measured by rotational viscomete...

Embodiment 2

[0033] Add 14.57 parts of talloleic acid, 8.66 parts of pentaerythritol, 0.11 parts of hypophosphorous acid, and 2.70 parts of refluxed xylene into the reactor in sequence, slowly raise the temperature to 120°C, start stirring, continue to heat up to 215°C, and keep warm until the acid value is ≤15mgKOH / g, lower the temperature to 150°C, add 10.16 parts of castor oil, 24.9 parts of phthalic anhydride and 12.69 parts of trimethylolpropane, start stirring, continue to heat up to 170°C, keep warm for 1h, and slowly heat up to 200°C within 4h, at 200°C Insulate and react at -220°C until the acid value is ≤12 mgKOH / g, lower the temperature to below 145°C, dilute with 26.2 parts of xylene, continue stirring for 40 minutes, filter, and discharge to obtain the clean-flavored quick-drying alkyd resin 2. The measured solid content of net taste quick-drying alkyd resin 2 is 70.1%, and the viscosity (25°C) measured by rotational viscometer NDJ-1 is 51000mPa·s.

Embodiment 3

[0035] Add 9.91 parts of soybean oleic acid, 11.57 parts of pentaerythritol, 0.13 parts of hypophosphorous acid, and 3.79 parts of refluxed xylene into the reactor in sequence, slowly raise the temperature to 110°C, start stirring, continue to heat up to 210°C, and keep warm until the acid value ≤ 15mgKOH / g, cool down to 150°C, add 5.51 parts of castor oil, 12.61 parts of phthalic anhydride, 14.13 parts of isophthalic acid, 13.76 parts of neopentyl glycol, 0.4 parts of maleic anhydride and 3.96 parts of adipic acid, start stirring, and continue to heat up to 170°C, Heat preservation reaction for 1 hour, slowly heat up to 200°C within 4 hours, heat preservation reaction at 200°C-220°C until acid value ≤ 10mgKOH / g, cool down to below 145°C, dilute with 24.22 parts of xylene, continue to stir for 45 minutes, filter, and release material, to obtain net flavor quick-drying alkyd resin 3. The measured solid content of net taste quick-drying alkyd resin 3 is 70.2%, and the viscosity...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com