UV light-cured wood coating and preparation method thereof

A technology of wood coatings and mixtures, applied in the field of coatings, which can solve problems such as strong odor and damage, and achieve the effect of good viscosity and fast curing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

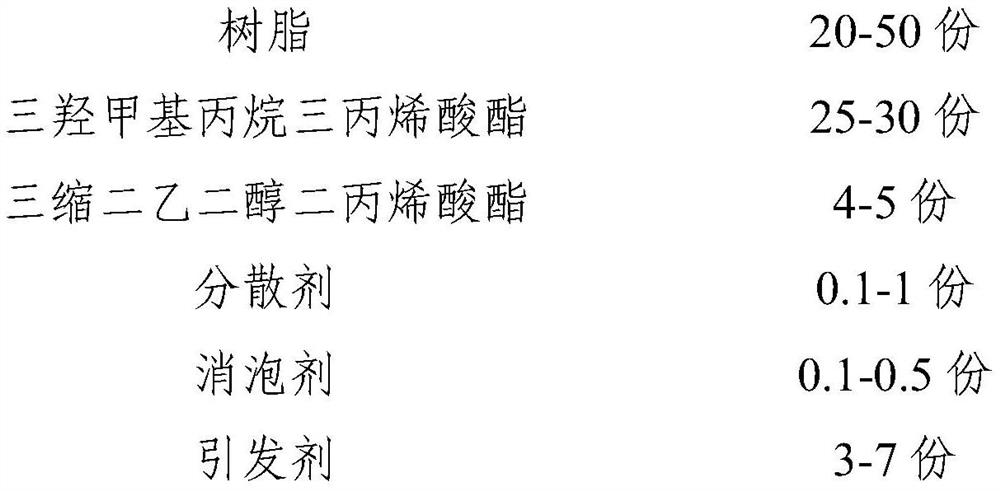

[0039] Present embodiment provides a kind of wood coating, by weight, its formula is as follows:

[0040]

[0041] Present embodiment provides the preparation method of above-mentioned woodware coating simultaneously, comprises the steps:

[0042] (1) Disperse epoxy acrylate 621-100, TMPTA, TPGDA, TPO and active amine at 1500r / min for 15min to obtain mixture I;

[0043] (2) Disperse the mixture I, dispersant and defoamer at 1200r / min for 8min to obtain mixture II;

[0044] (3) Disperse the mixture II and talcum powder at 1200r / min for 20min to obtain.

Embodiment 2

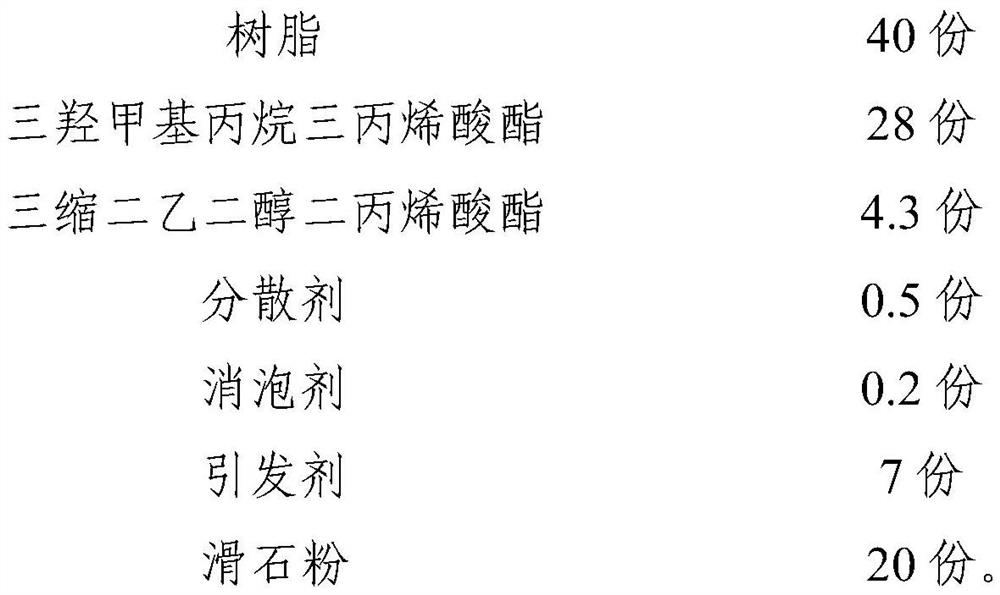

[0046] Present embodiment provides a kind of wood coating, by weight, its formula is as follows:

[0047]

[0048] Present embodiment provides the preparation method of above-mentioned woodware coating simultaneously, comprises the steps:

[0049] (1) Disperse modified bisphenol A epoxy acrylate 6100D-85, TMPTA, TPGDA, PBZ and active amine at 1500r / min for 15min to obtain mixture I;

[0050] (2) Disperse the mixture I, dispersant and defoamer at 1200r / min for 8min to obtain mixture II;

[0051] (3) Disperse the mixture II and talcum powder at 1200r / min for 20min to obtain.

Embodiment 3

[0053] Present embodiment provides a kind of wood coating, by weight, its formula is as follows:

[0054]

[0055]

[0056] Present embodiment provides the preparation method of above-mentioned woodware coating simultaneously, comprises the steps:

[0057] (1) Disperse epoxy acrylate 621-100, TMPTA, TPGDA, OMBB and active amine at 1500r / min for 15min to obtain mixture I;

[0058] (2) Disperse the mixture I, dispersant and defoamer at 1200r / min for 8min to obtain mixture II;

[0059] (3) Disperse the mixture II and talcum powder at 1200r / min for 20min to obtain.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com