Method for hydrolyzing adenosine through cation exchange resin catalysis-separation coupled technology

A cation exchange, adenosine technology, applied in the field of biochemical industry, can solve the problems of heavy pollution, uneconomical, complex production route, etc., and achieve the effect of reducing production cost and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

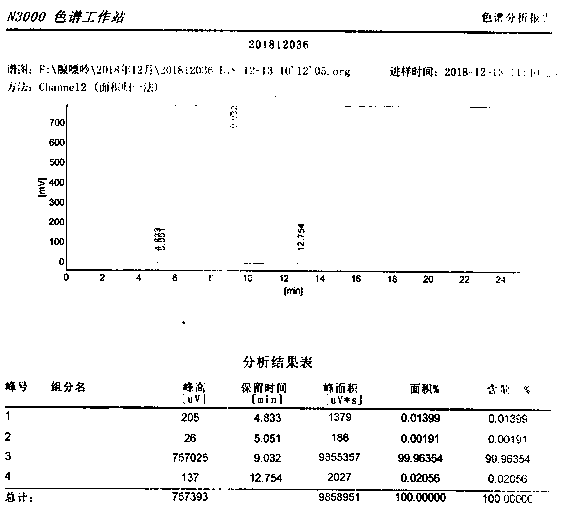

Image

Examples

Embodiment 1

[0020] Step S1: First put 450g of demineralized water into the reactor, start stirring at the same time, then put 25g of adenosine into the reactor, raise the temperature to 60°C through the jacket, then add 80g of regenerated cation exchange resin and keep it for 2 hours Make adenosine absorbed by the cation exchange resin, then adjust the temperature of the reaction system to 90-95°C, keep the reaction at 60°C for 12 hours after the solution gradually dissolves, then stop heating, and cool down to room temperature through circulating water, and the reaction The liquid is filtered through the filter tank, and the cation exchange resin adsorbed with adenine and the jellyfish solution containing D-ribose are obtained after filtration;

[0021] Step S2: Soak the cation exchange resin obtained by filtering step S1 with a molar concentration of 1mol / L sodium hydroxide solution (wherein the amount of sodium hydroxide is 22g), then filter the filtrate containing adenine obtained by t...

Embodiment 2

[0024] Step S1: First put 500g of demineralized water into the reactor, start stirring at the same time, then put 28g of adenosine into the reactor, raise the temperature to 60°C through the jacket, then add 90g of regenerated cation exchange resin, and keep it for 2 hours Make adenosine absorbed by the cation exchange resin, then adjust the temperature of the reaction system to 90-95°C, keep the reaction at 60°C for 12 hours after the solution gradually dissolves, then stop heating, and cool down to room temperature through circulating water, and the reaction The liquid is filtered through the filter tank, and the cation exchange resin adsorbed with adenine and the jellyfish solution containing D-ribose are obtained after filtration;

[0025] Step S2: Soak the cation exchange resin obtained by filtering step S1 with a molar concentration of 1mol / L sodium hydroxide solution (wherein the amount of sodium hydroxide is 25g), then filter the filtrate containing adenine obtained by ...

Embodiment 3

[0028] Step S1: First put 550g of demineralized water into the reactor, start stirring at the same time, then put 30g of adenosine into the reactor, raise the temperature to 60°C through the jacket, then add 85g of regenerated cation exchange resin and keep it for 2 hours Make adenosine absorbed by the cation exchange resin, then adjust the temperature of the reaction system to 90-95°C, keep the reaction at 60°C for 12 hours after the solution gradually dissolves, then stop heating, and cool down to room temperature through circulating water, and the reaction The liquid is filtered through the filter tank, and the cation exchange resin adsorbed with adenine and the jellyfish solution containing D-ribose are obtained after filtration;

[0029]Step S2: Soak the cation exchange resin obtained by filtering step S1 with a molar concentration of 1mol / L sodium hydroxide solution (wherein the amount of sodium hydroxide is 28g), then filter the filtrate containing adenine obtained by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com