Vacuum pump bottle

A vacuum pump and packaging bottle technology, applied in the field of packaging, can solve the problems of affecting the use effect of packaging bottles, unable to achieve sealing, and unable to discharge normally, and achieve the effect of simple structure, low manufacturing cost, and not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

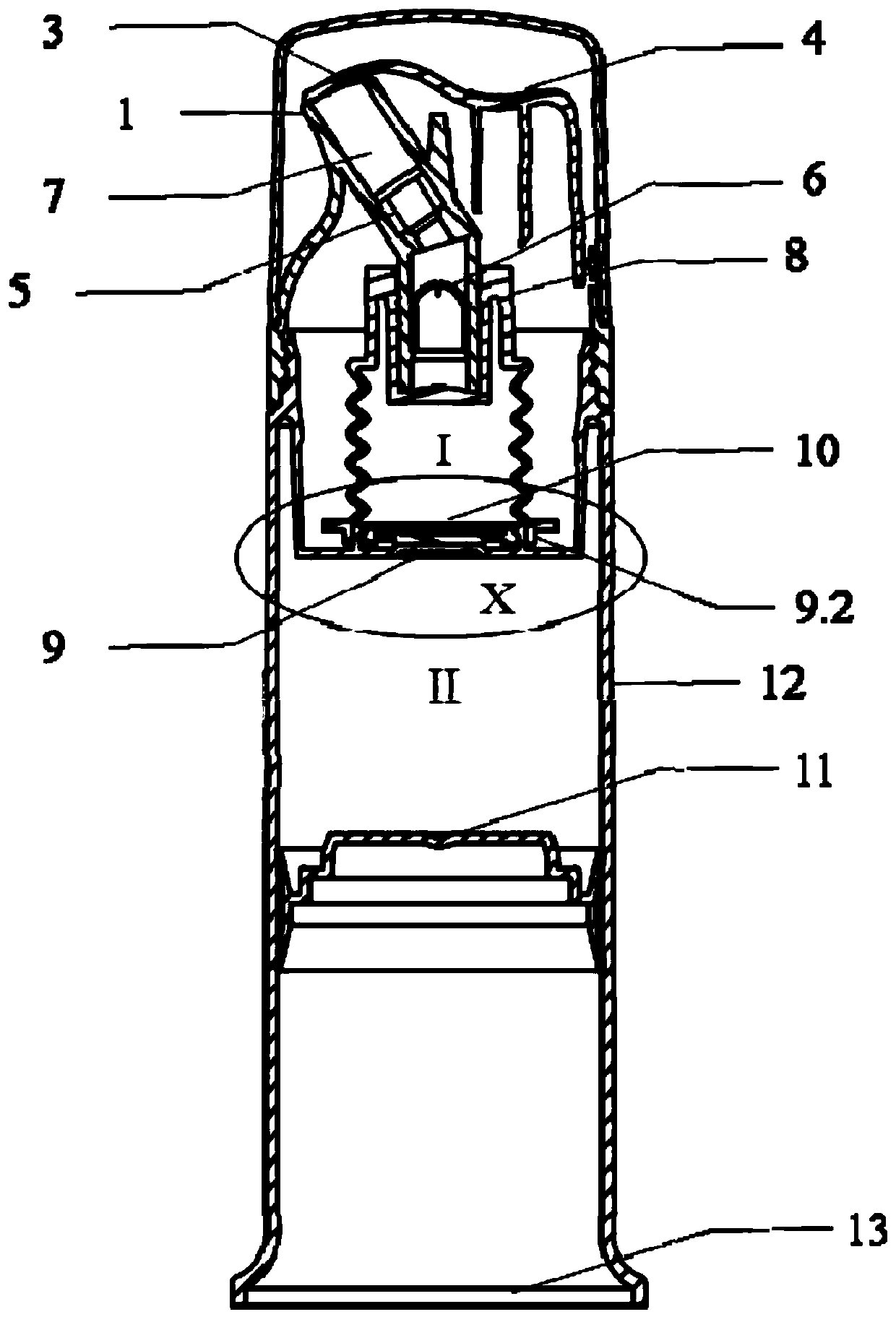

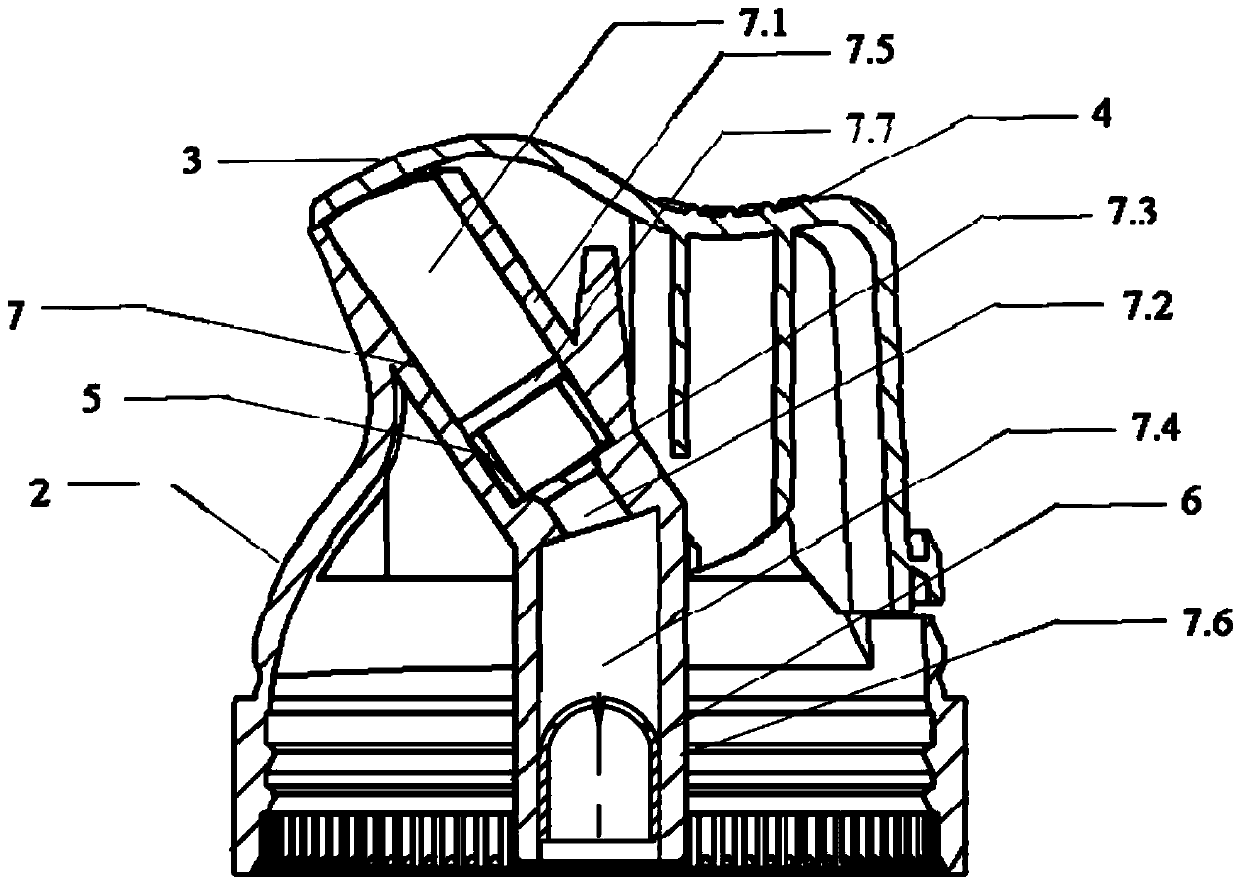

[0065] A vacuum-pumped packaging bottle, such as figure 1 with figure 2 As shown, it includes a pump head 1, an elastic body 8, a sealing pair, a cylindrical bottle body 12, a piston 11 and a base 13;

[0066] The pump head 1 is installed on the top of the cylindrical bottle body 12, the base 13 is installed on the bottom of the cylindrical bottle body 12, the piston 11 is installed at the bottom of the cylindrical bottle body 12, and the elastic body 8 is fixed on the bottom of the cylindrical bottle body 12. The upper part, the sealing pair is fixed in the middle part between the piston 11 and the elastic body 8 in the cylindrical bottle body 12; the discharge pipe 7, the elastic body 8 and the sealing pair form a closed discharge chamber (cavity 1), and the sealing pair , the piston 11 and the cylindrical bottle body 12 form a closed material storage chamber (chamber II);

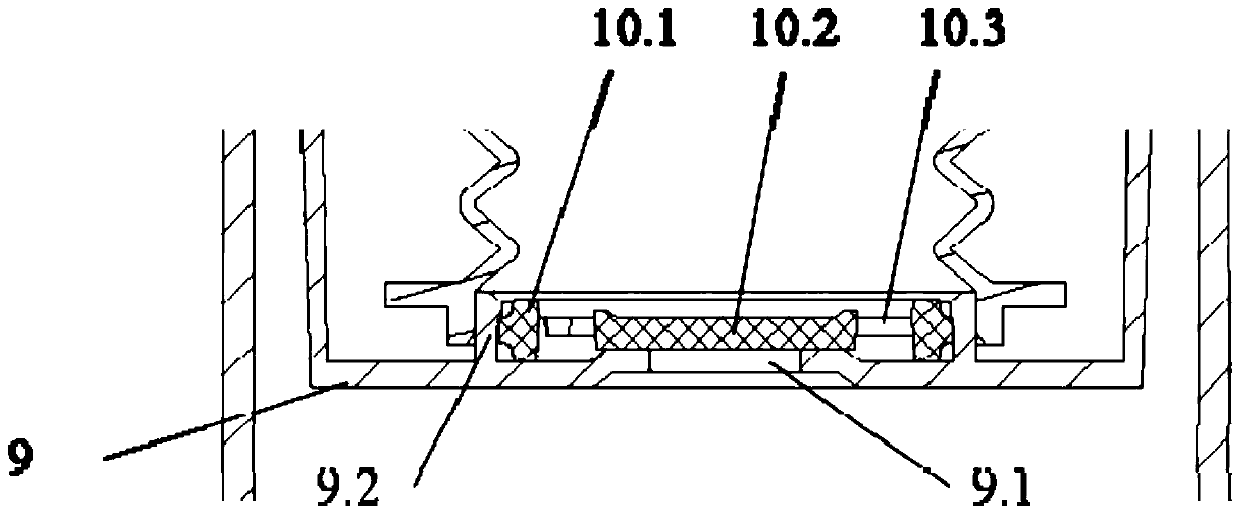

[0067] The sealing pair is mainly composed of a sealing seat 9 and an elastic sealing sheet 10 fix...

Embodiment 2

[0088] A vacuum-pumped packaging bottle, which is basically the same as Embodiment 1, except that the shape of the through hole c in the pump head and the cover body, the through hole c is similar to the shape of a truncated cone, and the difference between it and the shape of a truncated cone is that the busbar It is an arc, and its one-way valve is a flip valve, such as Figure 7-10 As shown, the cover body is a spherical structure, and a part of the cover body cut with a plane has the same shape and size as the through hole c.

Embodiment 3

[0090] A vacuum-pumped packaging bottle, which is basically the same as Embodiment 1, except that the pump head, as shown in Figure 26, is not provided with a cross valve, but only with a flip valve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com