Anti-static flame-retardant composite fabric and preparation method thereof

A flame-retardant composite and anti-static technology, which is applied in the field of fabric production, can solve problems affecting law enforcement personnel to perform tasks, affect appearance and comfort, and attack by high-temperature flames, so as to shorten the film-forming time and ensure safety and stability. , the effect of preventing static electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

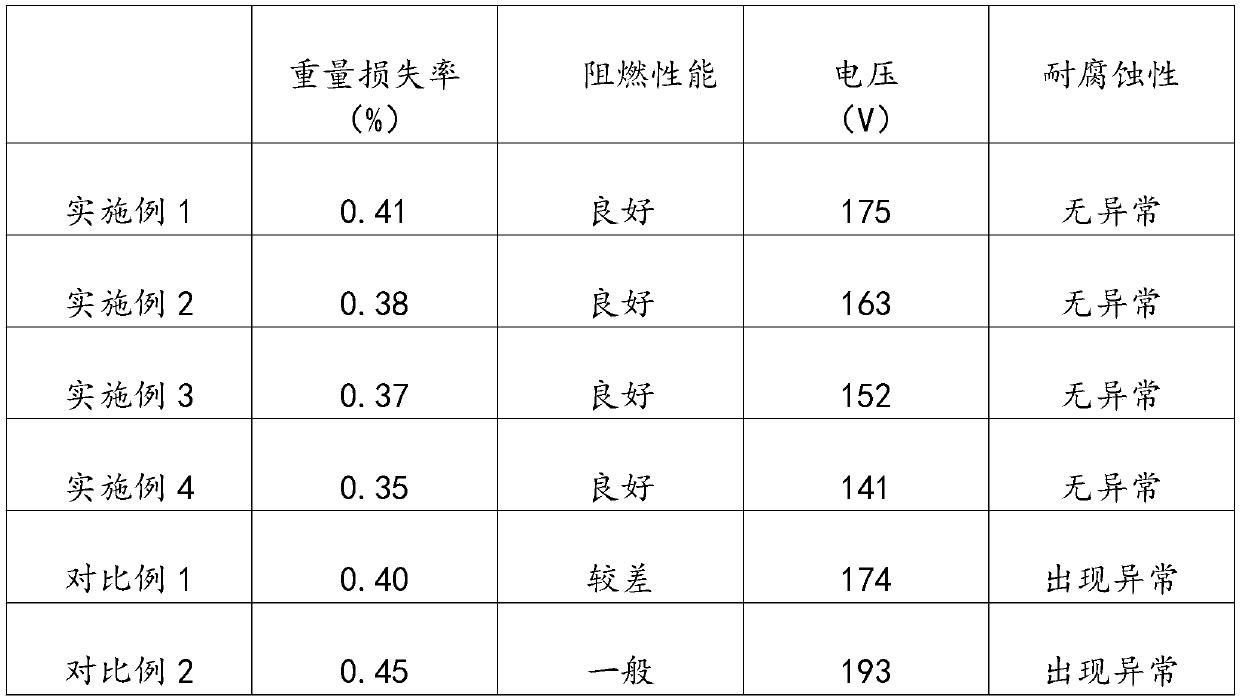

Embodiment 1

[0040] A method for preparing an antistatic flame retardant composite fabric, comprising the steps of:

[0041] Step S1, weighing the following raw materials in parts by weight: 55 parts of silk, 35 parts of ice silk, 35 parts of graphite fiber, 25 parts of modified acetate fiber, 5 parts of silicone resin, and 25 parts of flame-retardant coating;

[0042]Step S2. Mix silk and ice silk cotton for weaving. During the weaving process, control the warp spacing to 0.8 cm and the weft spacing to 1.0 cm to obtain a comfortable fabric with a warp yarn density of 80 yarns / cm and a weft yarn density of 70 yarns / cm. breathable fabric;

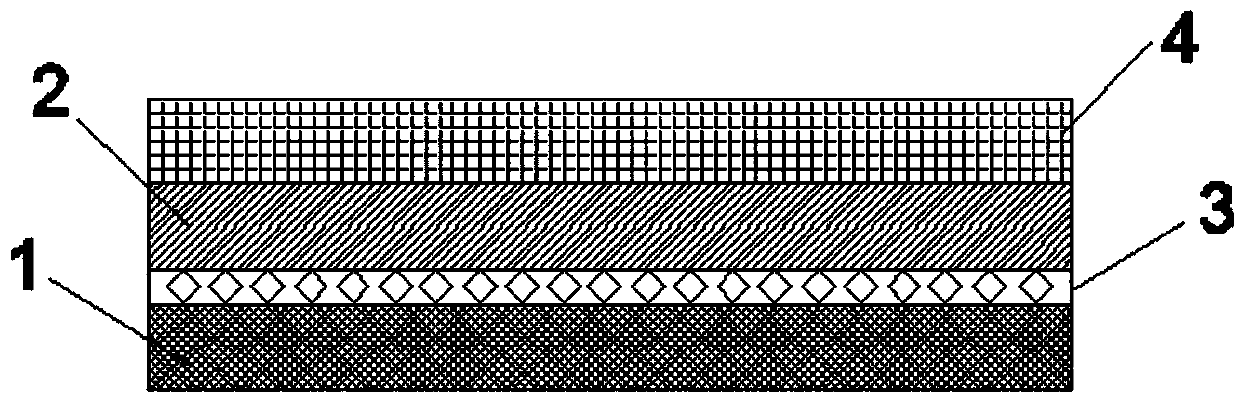

[0043] Step S3, making the first fabric layer and the second fabric layer from the air-permeable fabric blended with silk and ice silk, and the first fabric layer is used as the base fabric layer;

[0044] Step S4, the graphite fiber is twisted into a conductive yarn with a twist of 20 twists / 5cm and the modified acetate fiber, and the conductive yarn i...

Embodiment 2

[0052] A method for preparing an antistatic flame retardant composite fabric, comprising the steps of:

[0053] Step S1, weighing the following raw materials in parts by weight: 58 parts of silk, 38 parts of ice silk, 38 parts of graphite fiber, 26 parts of modified acetate fiber, 8 parts of silicone resin, and 27 parts of flame-retardant coating;

[0054] Step S2. Mix silk and ice silk cotton for weaving. During the weaving process, control the warp spacing to 0.8 cm and the weft spacing to 1.0 cm to obtain a comfortable fabric with a warp yarn density of 80 yarns / cm and a weft yarn density of 70 yarns / cm. breathable fabric;

[0055] Step S3, making the first fabric layer and the second fabric layer from the air-permeable fabric blended with silk and ice silk, and the first fabric layer is used as the base fabric layer;

[0056] Step S4, the graphite fiber is twisted into a conductive yarn with a twist of 20 twists / 5cm and the modified acetate fiber, and the conductive yarn ...

Embodiment 3

[0064] A method for preparing an antistatic flame retardant composite fabric, comprising the steps of:

[0065] Step S1, weighing the following raw materials in parts by weight: 60 parts of silk, 45 parts of ice silk, 45 parts of graphite fiber, 28 parts of modified acetate fiber, 13 parts of silicone resin, and 30 parts of flame-retardant coating;

[0066] Step S2. Mix silk and ice silk cotton for weaving. During the weaving process, control the warp spacing to 0.8 cm and the weft spacing to 1.0 cm to obtain a comfortable fabric with a warp yarn density of 80 yarns / cm and a weft yarn density of 70 yarns / cm. breathable fabric;

[0067] Step S3, making the first fabric layer and the second fabric layer from the air-permeable fabric blended with silk and ice silk, and the first fabric layer is used as the base fabric layer;

[0068] Step S4, the graphite fiber is twisted into a conductive yarn with a twist of 20 twists / 5cm and the modified acetate fiber, and the conductive yarn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com