Preparation method and application of ferroporphyrin modified mesoporous silica composite material

A technology of mesoporous silica and composite materials, which can be used in chemical instruments and methods, oxidized water/sewage treatment, medical preparations with inactive ingredients, etc., and can solve the problem that catalysts cannot be used as loaded drug delivery systems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Example 1, preparation of porphyrin iron modified mesoporous silica composite material

[0044] The preparation method of the porphyrin iron modified mesoporous silica composite material of the present embodiment comprises the following steps:

[0045] S1. Prepare and obtain SBA-15;

[0046] S2. APTES-SBA-15 was prepared by using SBA-15 prepared in S1;

[0047] S3, take porphyrin iron (FeIX), evenly disperse it in dimethyl sulfoxide (DMSO) solution, add APTES-SBA-15 prepared in S2, keep stirring at constant temperature, centrifuge to remove supernatant, wash and dry, Obtain FeIX-SBA-15, which is porphyrin iron modified mesoporous silica composite material.

[0048] In S3, the specific process of constant temperature and continuous stirring is: 70 ° C ± 5 ° C constant temperature oil bath continuous stirring for 8 ± 1 hours; the specific process of centrifugation is: 5000 ± 500 rpm centrifugation for 5 ± 1 minutes; the washing The specific process is: first wash with wa...

Embodiment 2

[0055] Embodiment 2, preparation load doxorubicin composite material

[0056] The preparation method of this embodiment loaded doxorubicin composite material comprises the following steps:

[0057] T1, using Example 1 to prepare and obtain porphyrin iron modified mesoporous silica composite material, namely FeIX-SBA-15;

[0058] T2. Take doxorubicin hydrochloride (DOX), dissolve it in deionized water and stir evenly to obtain a DOX solution; wherein, the concentration of the DOX solution is 2 ± 1 mg / ml;

[0059] T3. Take the FeIX-SBA-15 obtained in T1, and disperse it into the DOX solution, and keep stirring at a constant temperature; wherein, the specific process of the constant temperature and continuous stirring is: keep stirring in a constant temperature water bath at 37°C±5°C for 24±2 hours ;

[0060] T4. Centrifuge the solution obtained in T3, remove the supernatant, wash and dry, and the resulting product is DOX / FeIX-SBA-15, which is the loaded doxorubicin composite m...

Embodiment 3

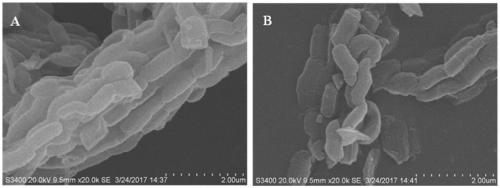

[0061] Embodiment 3, scanning electron microscope analysis

[0062] The DOX / FeIX-SBA-15 of SBA-15 and embodiment 2 is done scanning electron microscope analysis, and the result is as follows figure 1 shown.

[0063] It can be seen from the figure that the shape of SBA-15 is regular and short rod-shaped. After modification and loading of DOX, the short rod-shaped regular structure does not change significantly, indicating that the morphology of SBA-15 will not be changed during the preparation of composite materials. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com