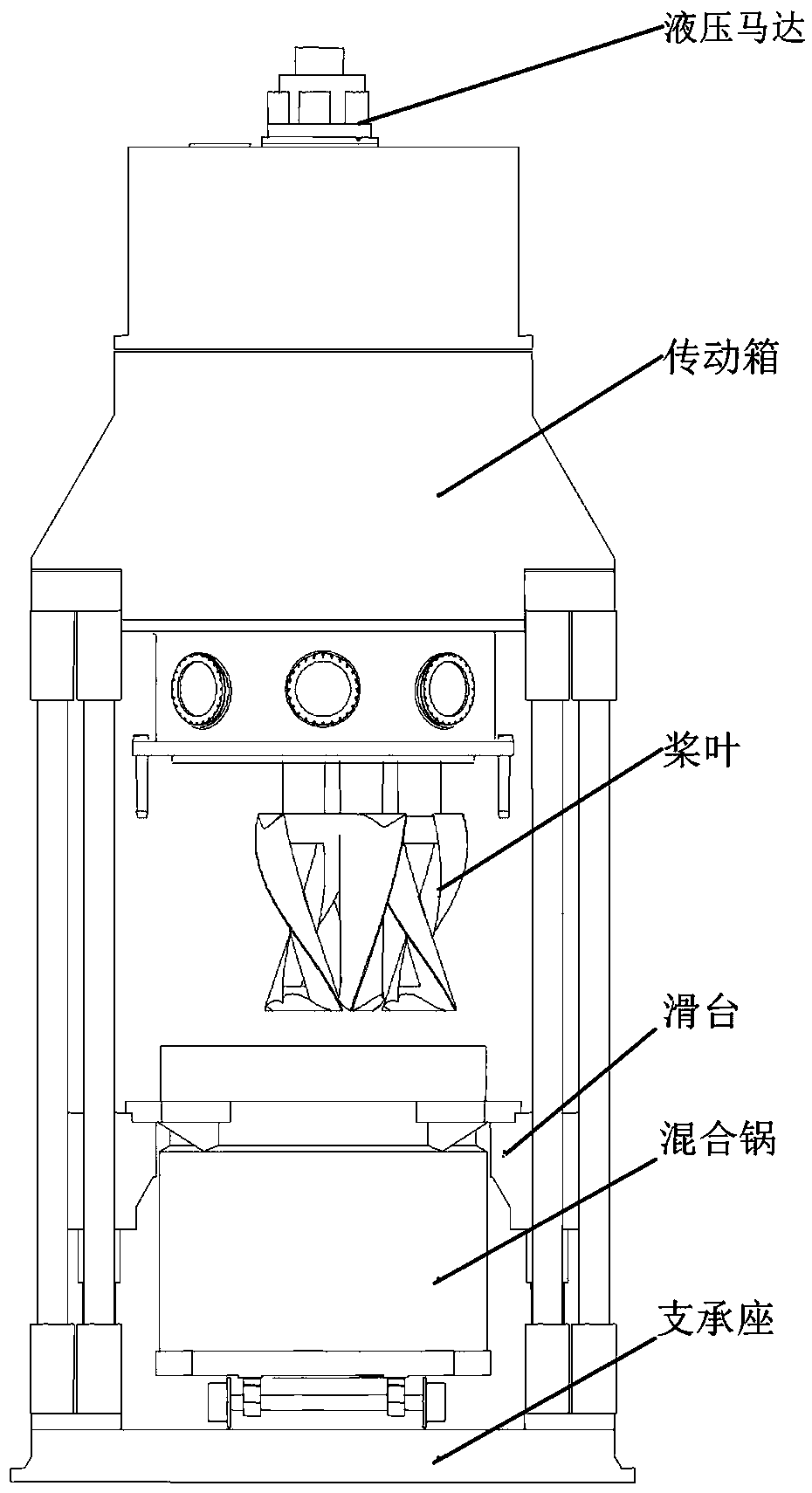

Mixing pot bottom discharge apparatus and application method thereof

A discharge device, pot bottom technology, applied in the direction of mixers, chemical instruments and methods, mixers with rotating stirring devices, etc., can solve the problem that the slurry is easy to infiltrate into the moving parts of the valve stem, the labor intensity of the operator is high, and it cannot be realized Remote control and other issues to achieve the effect of reducing slurry residue, simple structure, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the examples, but the protection scope of the present invention is not limited to the scope expressed in the examples.

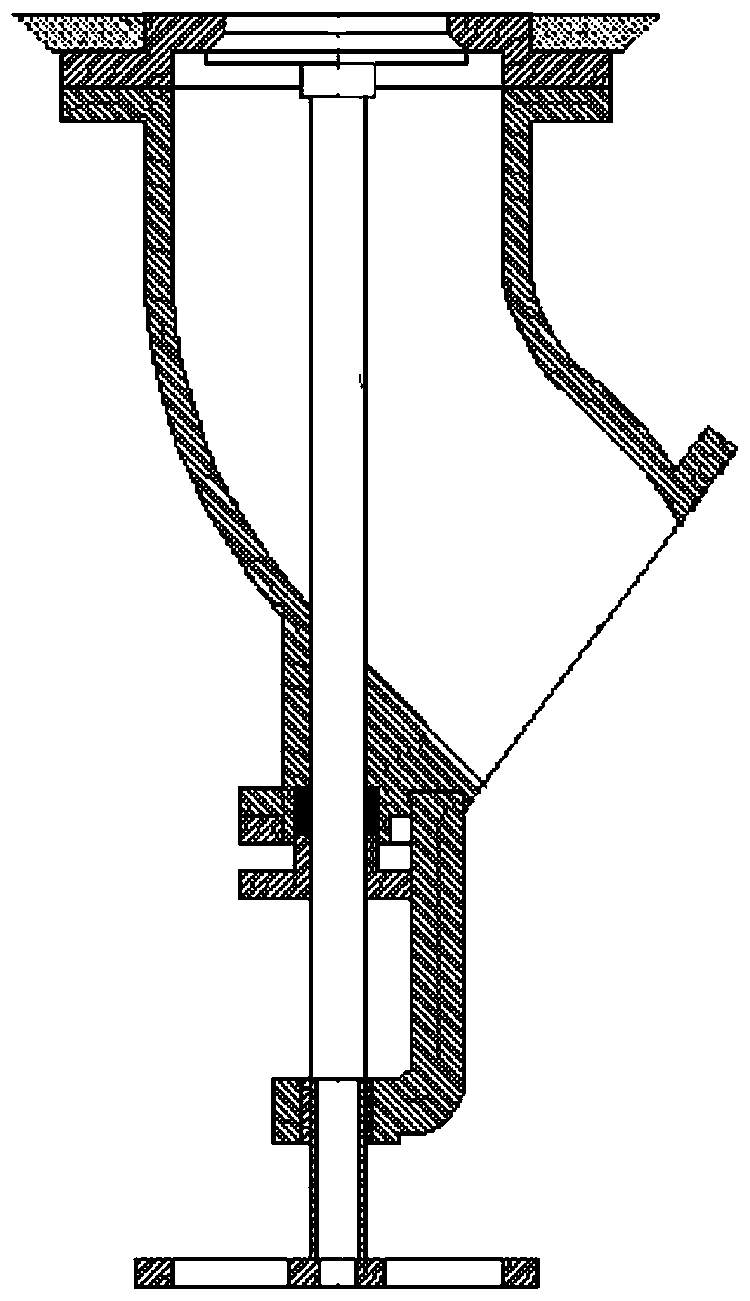

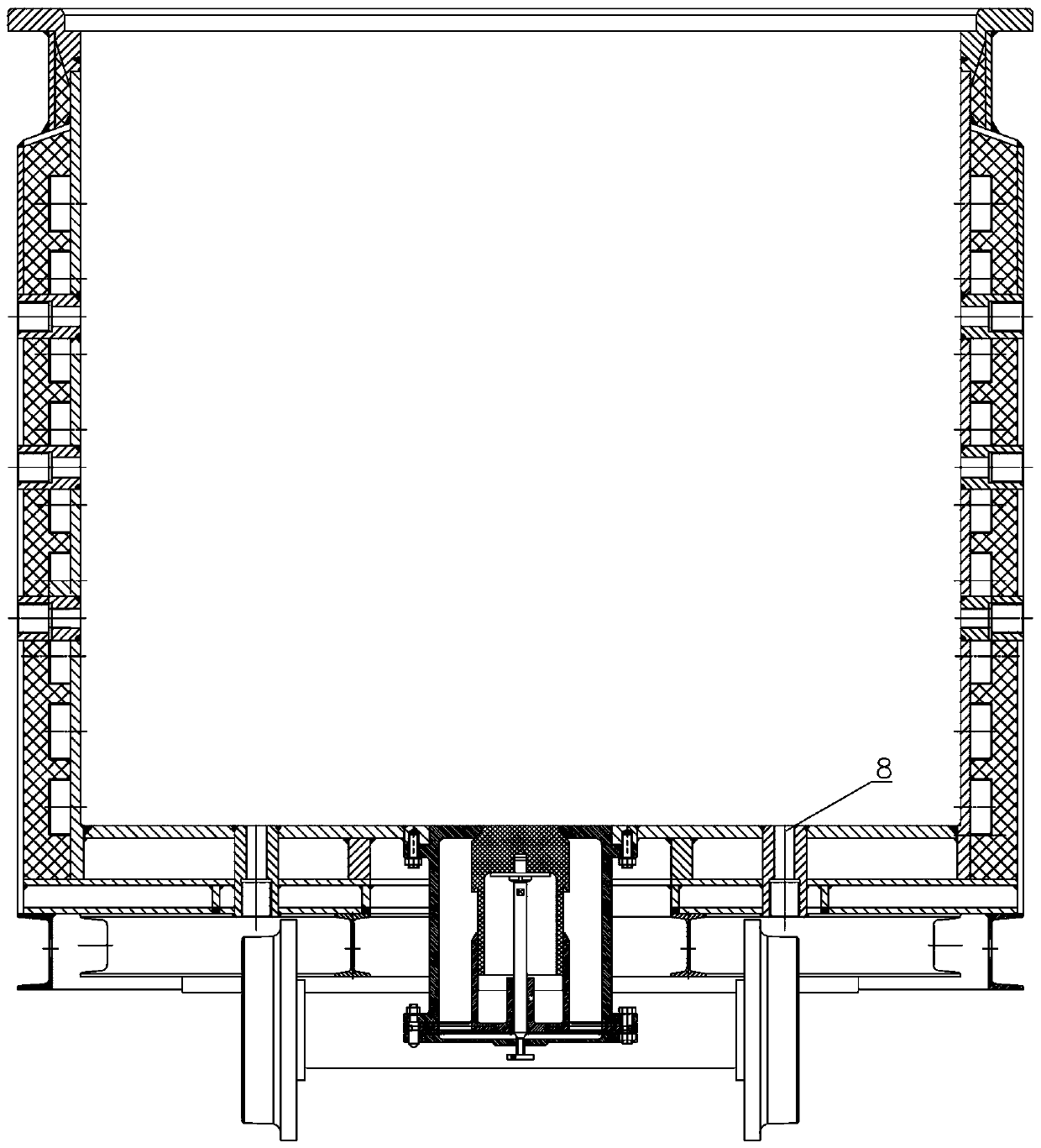

[0032] Such as Figure 3-9 As shown, a mixing pot bottom discharge device includes a mixing pot 8, a valve body 7 is installed at the bottom of the valve body, and the center of the top plate of the valve body is provided with a discharge port 9, which is blocked by a valve core 5 at the discharge port. The lower part of the core is connected to the valve core seat 3 through the ejector rod 4, and a protective cover 1 is provided under the valve core seat 3. The lower edge of the valve body, the edge of the valve core seat and the edge of the protective cover are connected and fixed, and the ejector rod runs through the valve. The back of the core seat is located above the protective cover, and the center of the protective cover is provided with a hole, and fastening bolts are i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com