Method for treating hexavalent chromium in solid wastes

A solid waste, hexavalent chromium technology, applied in the direction of the protection device against harmful chemicals, etc., can solve the problems of poor treatment effect, small treatment capacity, large consumption of acid and alkali, etc. Reagent consumption, mild reaction conditions, and avoidance of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

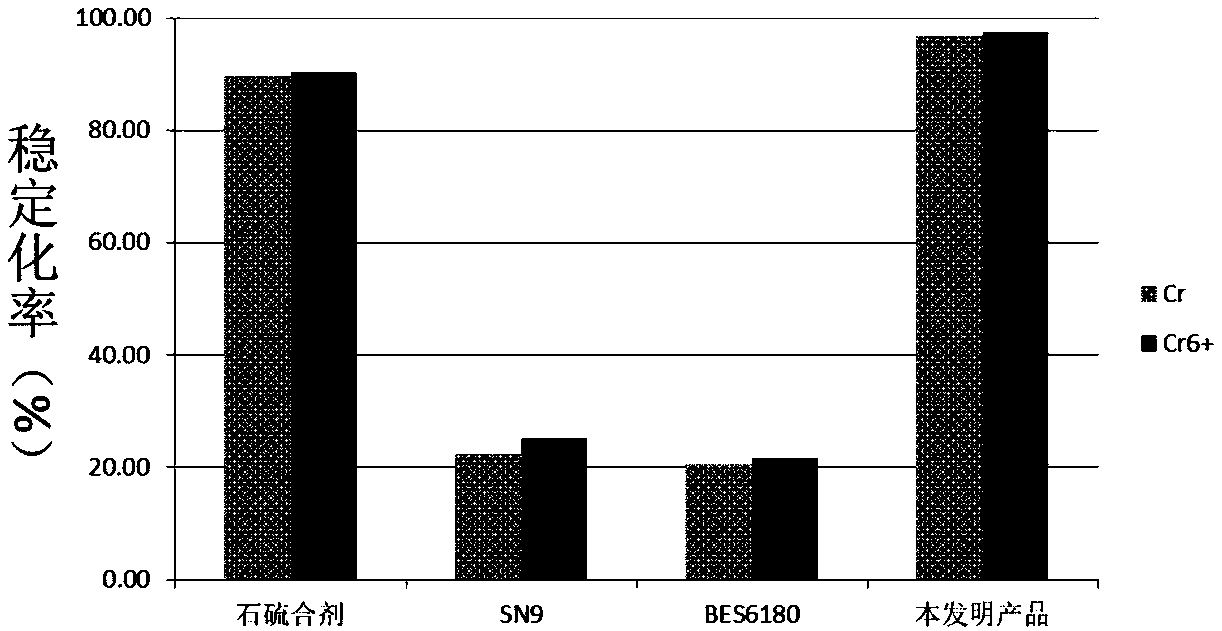

[0040] Example 1 Heavy metal stabilization treatment method for heavy metal dust in a waste incineration power plant along the coast

[0041] Take dust from a waste incineration power plant in the coastal area, divide it into 4 groups, each group is 100g, and add 4g of lime sulfur, SN9 heavy metal stabilizer, BES6180 heavy metal stabilizer and hydrogenated disulfide shown in formula I to the 4 groups of samples. Carboxylate heavy metal stabilizer, in formula I, R 1 is an alkyl group with less than 8 C atoms, R 2 for H, M for Na + , add 25g of water and stir evenly to make a fly ash solidified sample, and cure for 24 hours.

[0042] According to HJ / T300-2007, the leaching toxicity test was carried out on the cured sample after stabilization treatment, and the leaching toxicity results are shown in Table 1.

[0043] Table 1 The leaching toxicity of heavy metal dust stabilized in a coastal waste incineration power plant

[0044]

[0045]As can be seen from Table 1, the hea...

Embodiment 2

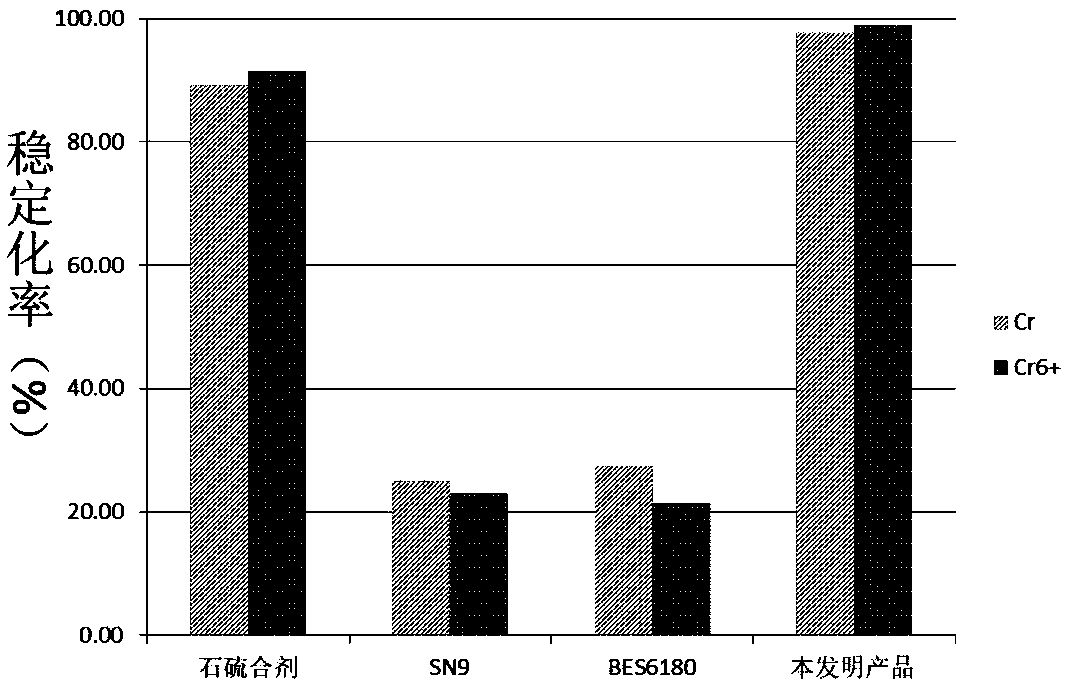

[0048] Embodiment 2 The heavy metal stabilization treatment method of industrial solid waste in North China

[0049] Take the northern industrial solid waste and divide it into 4 groups, each group of 100g, add 4g of lime sulfur, SN9 heavy metal stabilizer, BES6180 heavy metal stabilizer and hydrogenated dithiocarboxylate shown in formula I to the 4 groups of samples Heavy metal stabilizer, R in formula I 1 for H, R 2 is H or an alkyl group with less than 8 C atoms, and M is NH 4 + ; Add 25g of water and stir evenly to make a solidified fly ash sample, and cure for 24 hours at a curing temperature of 20-25°C.

[0050] According to HJ / T300-2007, the leaching toxicity test is carried out on the stabilized solid waste, and the leaching toxicity is detailed in Table 2.

[0051] Table 2 Leaching Toxicity of Heavy Metal Stabilization Treatment of Solid Waste in North Industries

[0052]

[0053] As can be seen from the data in table 2, adopt the industrial solid waste Cr and...

Embodiment 3

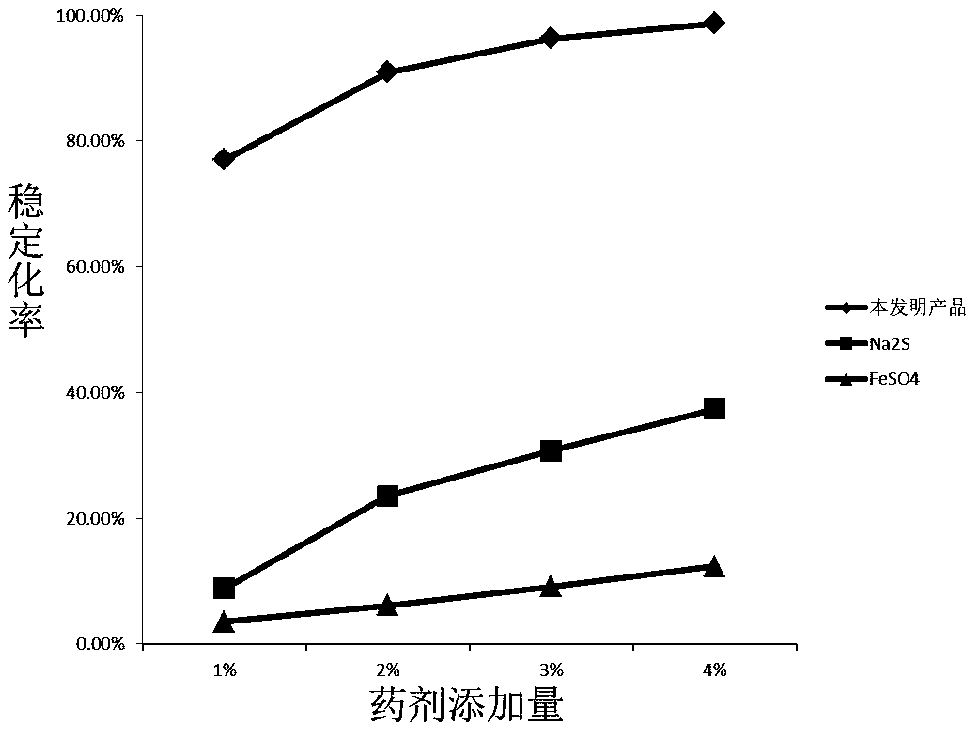

[0055] Example 3 Stabilization treatment method of waste incineration fly ash in a waste incineration power plant in Guangdong

[0056] In order to compare different additions of reducing agents on Cr and Cr 6+ The reduction effect of waste incineration fly ash from a waste incineration power plant in Guangdong was taken and divided into 12 groups, each group 100g.

[0057] Add different concentrations (mass fraction 1%, 2%, 3%, 4%) of sodium sulfide, FeSO 4 ·H 2 O and the hydrogenated dithiocarboxylate heavy metal stabilizer shown in formula I of the present invention, R 1 for H, R 2 for H, for M

[0058] K + , treatment for comparison, add 30g of water to make a solidified block, curing time 24 hours.

[0059] According to HJ / T300-2007, the leaching toxicity test of the stabilized solidified block is carried out, and the relevant leaching toxicity is shown in Table 3.

[0060] Table 3 Leaching toxicity of waste incineration fly ash stabilization treatment in a waste i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com