Fish quality maintaining and conditioning processing method

A processing method and fish meat technology, which are applied in food mechanical processing, food ingredients as humectants, food freezing, etc., can solve the problems of strong fishy or earthy smell, flavor deterioration and spoilage, which affect the development of processing industry, etc. , to achieve high muscle texture, improve the ability to resist freezing and denaturation, and maintain the effect of texture characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

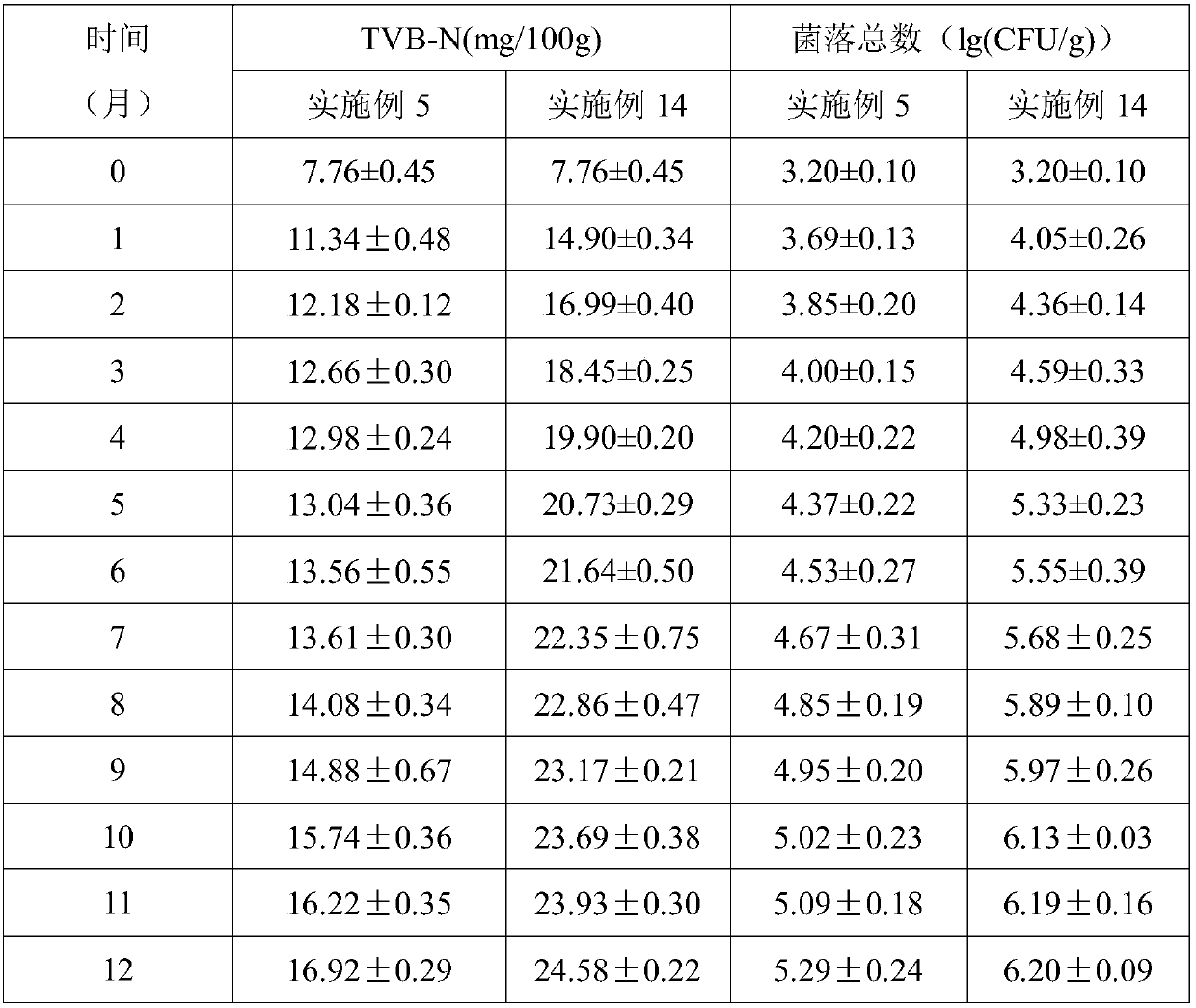

Examples

Embodiment 1

[0043] Embodiment 1: Frozen conditioning silver carp fillet processing

[0044] 1) Silver carp pretreatment: commercially available silver carp is rested in 20°C water for 12 hours, and then transferred to -1.5°C ecological ice-warm water, in which the concentration of CO in the ecological ice-warm water is 0.25ppm. The mass ratio of ice-warm water is 1:10, and the resting time is 12 hours, so that the muscle fibers of the fish will contract cold, and the sarcomeres of the myofibrils will change from the stretched state of 2.30 μm to the contracted state of 2.10 μm.

[0045] 2) Pre-treatment of silver carp: kill the live silver carp that has undergone resting treatment, remove the scales, head and viscera, take the fish body, wash, drain, cut into fish fillets with a thickness of 3-4 mm, and weigh heavy, spare.

[0046] 3) Pulse breathing tumbling of fish fillets and coating solid film on the surface of fish meat: Weigh 1000kg silver carp fillets and put them into a vacuum tu...

Embodiment 2

[0048] Embodiment 2: processing of frozen conditioning silver carp fillets

[0049] 5) Silver carp pretreatment: commercially available silver carp is kept in 25°C water for 12 hours, and then transferred to -1.5°C ecological ice-warm water, in which the concentration of CO in the ecological ice-warm water is 0.25ppm. The mass ratio of ice-warm water is 1:2, and rest for 3 hours, so that the muscle fibers of the fish will contract cold, and the sarcomeres of the myofibrils will change from the stretched state of 2.30 μm to the contracted state of 2.00 μm.

[0050] 6) Pre-treatment of silver carp: Kill the live silver carp that has undergone resting treatment, remove the scales, heads and viscera, take the fish body, wash, drain, cut into fish fillets with a thickness of 3-4 mm, and weigh them. heavy, spare.

[0051] 7) Pulse breathing tumbling of fish fillets and coating and solid film on the surface of fish meat: Weigh 1000kg silver carp fillets and add them to the vacuum tu...

Embodiment 3

[0053] Embodiment 3: the making of frozen conditioning bighead carp fillets

[0054] 1) Pretreatment of bighead carp: commercially available bighead carp is kept in 23°C water for 15 hours, and then transferred to -2°C ecological ice-warm water, where the concentration of CO in the ecological ice-warm water is 0.10ppm. The mass ratio of ice-warm water is 1:5, and the resting time is 18 hours, so that the muscle fibers of the fish will contract cold, and the sarcomeres of the myofibrils will change from the stretched state of 2.30 μm to the contracted state of 1.90 μm.

[0055] 2) Pre-treatment of bighead carp: kill the pre-treated live bighead carp, remove the scales, head and viscera, take the body part, wash, drain, cut into fish fillets with a thickness of 3-4mm, weigh them, spare.

[0056] 3) Pulse-type breathing tumbling of bighead carp fillets and coating and solid film on the surface of fish meat: Weigh 1000kg bighead carp fillets and put them into a vacuum tumbler, ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com