Mixture applied to hole injection layer and organic light emitting device thereof

A technology of organic light-emitting devices and hole injection layers, which is applied in the fields of electric solid-state devices, semiconductor devices, semiconductor/solid-state device manufacturing, etc., to achieve the effects of low driving voltage, high efficiency, and simple manufacturing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

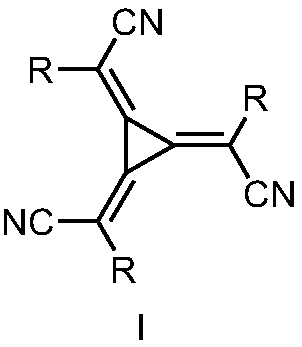

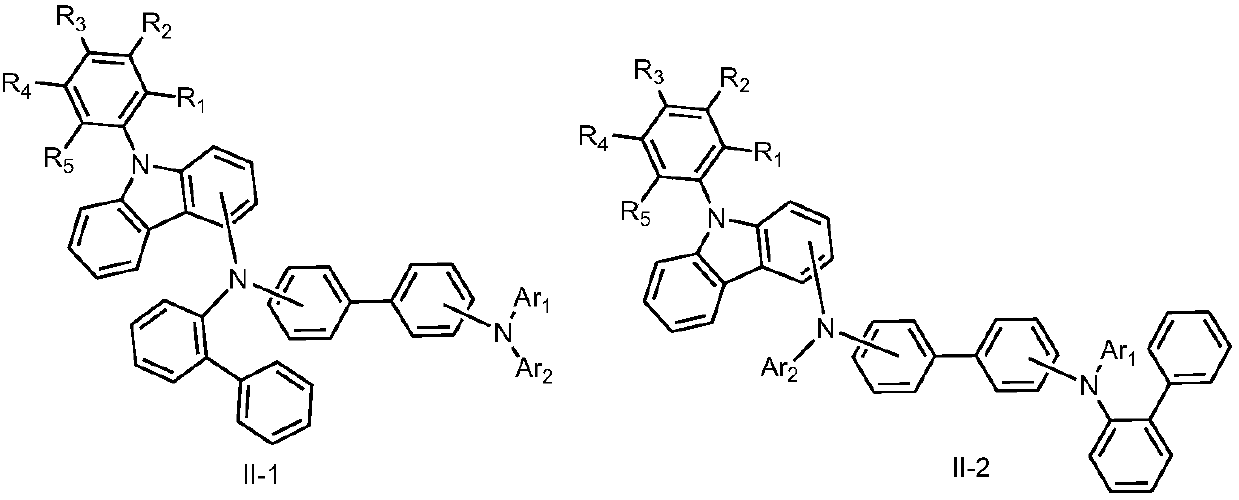

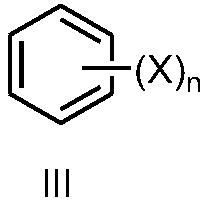

Method used

Image

Examples

Embodiment 1

[0067] Embodiment 1: the preparation of compound TM8

[0068]

[0069] Add NaH (1.6 g, 16 mmol) into 40 mL of ethylene glycol dimethyl ether, and slowly drop it into 10 mL of pentafluorophenylacetonitrile (4 g, 20 mmol) in ethylene glycol dimethyl ether with stirring in an ice bath. The ice bath was removed, and the reaction solution was gradually warmed up to room temperature, and reacted at room temperature for 15 minutes. The reaction liquid was cooled to 0°C again, and a solution of tetrachlorocyclopropene (0.9 g, 5 mmol) in 10 mL of ethylene glycol dimethyl ether was slowly added dropwise into the reaction liquid. The reaction solution gradually turned dark red, warmed up to room temperature, and continued to stir for 24 h. After the reaction, pour the reaction solution into 1.2L of ice water, adjust the pH value of the resulting mixture to 1 with concentrated hydrochloric acid (add about 24ml of hydrochloric acid), then extract with 3×50ml of chloroform, combine the ...

Embodiment 2

[0071] Embodiment 2: the preparation of compound TM10

[0072]

[0073] Compound 1-2 in Example 1, ie, pentafluorophenylacetonitrile, was replaced by equimolar compound 2-2, and the other steps were the same to obtain compound 10. Mass Spectrum m / z: 800.75 (calculated: 800.98). Theoretical element content (%)C 30 f 21 N 3 : C, 44.97; F, 49.79; N, 5.24 The measured element content (%): C, 44.98; F, 49.77; N, 5.25. The above results confirmed that the obtained product was the target product.

Embodiment 3

[0074] Embodiment 3: the preparation of compound 1

[0075]

[0076] Synthesis of Intermediate A1

[0077] Tri-tert-butylphosphine (3 mL of a 1.0M solution in toluene, 7.32 mmol), palladium acetate (0.4 g, 1.83 mmol) and sodium tert-butoxide (22.8 g, 238 mmol) were added to bis-(4-biphenyl) A solution of the amine (58.7 g, 183 mmol) and 4-bromo-4-iodobiphenyl (65.5 g, 183 mmol) in degassed toluene (500 mL), and the mixture was heated at reflux for 2 hours. The reaction mixture was cooled to room temperature, diluted with toluene and filtered through celite. The filtrate was diluted with water and extracted with toluene, and the combined organic phases were evaporated under vacuum. The residue was filtered through silica gel (heptane / dichloromethane) and crystallized from isopropanol. Intermediate A1 was obtained (90.7 g, 90% of theory).

[0078] Mass Spectrum m / z: 551.13 (calculated: 551.12). Theoretical element content (%)C 36 h 26 BrN: C, 78.26; H, 4.74; Br, 14.46;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com