Super-power-density diesel engine with sequential intervention type composite combustion systems

A combustion system and power density technology, applied to combustion engines, internal combustion piston engines, mechanical equipment, etc., can solve problems such as poor reliability and unstable combustion, and achieve the effects of ensuring reliability, improving combustion rate, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

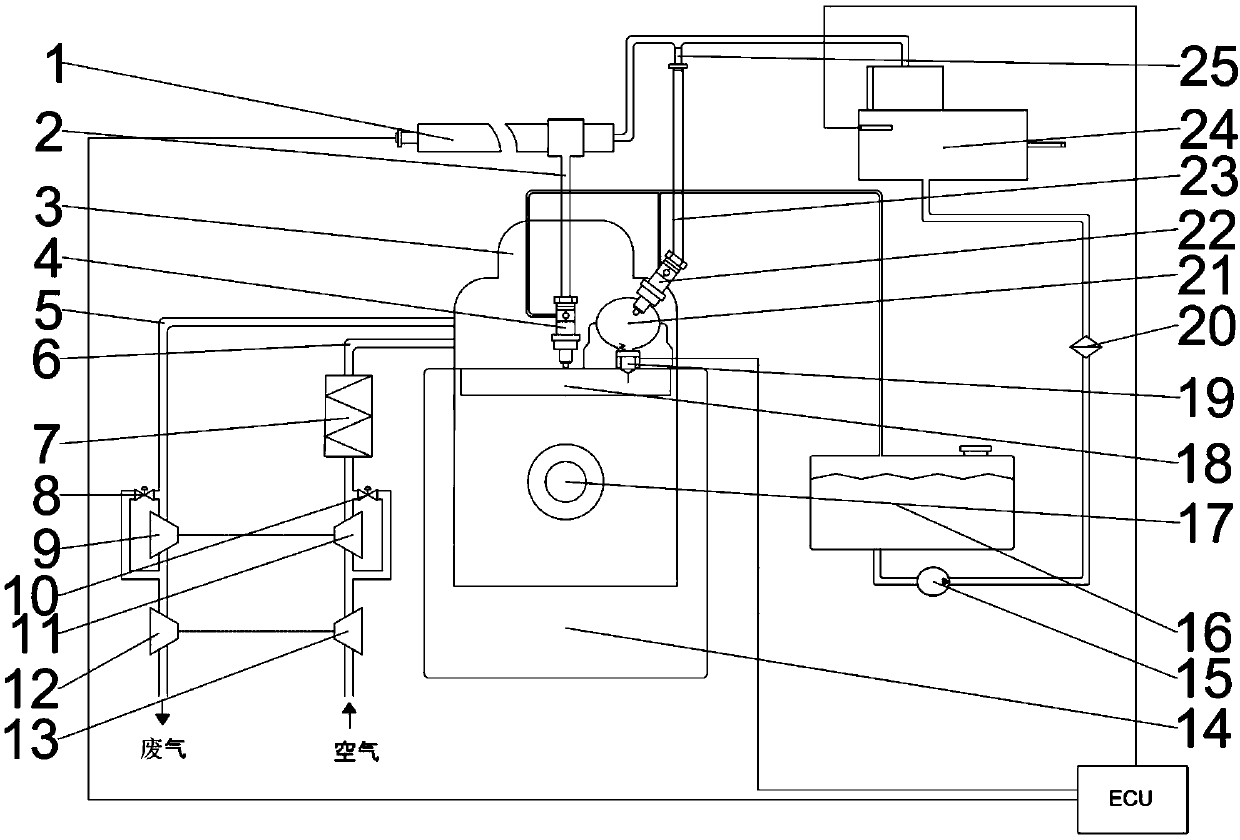

[0015] The present invention is described in detail below in conjunction with accompanying drawing:

[0016] like figure 1 As shown, when the non-combat state is in non-combat state, the auxiliary combustion system is closed, and it works in the mainstream ultra-high pressure electronically controlled high-pressure direct-injection diesel engine mode, that is, the pressure-accumulated common rail fuel injection system, which includes 1. Common rail pipe 2. High pressure fuel pipe 3 .Cylinder head 4. Main combustion chamber fuel injector 14. Cylinder block 15. Low-pressure fuel supply pump 16. Fuel tank 17. Piston 18. Main combustion chamber 19. Hydraulic valve 20. Filter 21. Sub-combustion chamber 22. Sub-combustion chamber Injection nozzle 23. High-pressure oil pipe 24. High-pressure oil supply pump, which can adopt 4.0 pressure ratio, 23-16 compression ratio, and 1.3 excess coefficient. Considering economy, heat load and mechanical load, the power rise is controlled at about...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com